To remove the cover of solar road studs, follow these steps: 1. Identify the type of cover, 2. Use appropriate tools, 3. Execute careful lifting, 4. Inspect for damage. The cover of solar road studs typically serves as protection for the internal components of the studs. It is important to handle this process delicately to avoid damaging the stud itself, as well as to ensure safety during removal. Start by identifying whether the cover is secured with screws, clips, or simply pressure-fitted. Use the necessary tools, such as a screwdriver or pry bar, to assist in the removal. When lifting the cover, focus on even pressure to prevent any fractures or cracks in the plastic casing. After removal, check for any structural damage to both the cover and the stud, as this can affect functionality. Adhering to these guidelines ensures efficient removal and maintains the integrity of the solar road studs.

1. INTRODUCTION TO SOLAR ROAD STUDS

Solar road studs, often referred to as solar pavement markers or solar LED road studs, have gained considerable popularity as a form of roadway safety and guidance. These devices operate without requiring external power sources, harnessing solar energy through integrated photovoltaic cells. Their use primarily revolves around enhancing visibility in low-light conditions, thus significantly contributing to road safety.

The objective behind their development stems from an essential need for effective traffic management systems that facilitate ease of navigation, particularly at night or during adverse weather conditions. Solar road studs serve not only practical purposes but also align with sustainable energy practices, offering an environmentally friendly alternative to traditional roadway lighting systems. Understanding their construction, functionality, and maintenance procedures are vital for those responsible for installation and upkeep.

2. COMPONENTS OF SOLAR ROAD STUDS

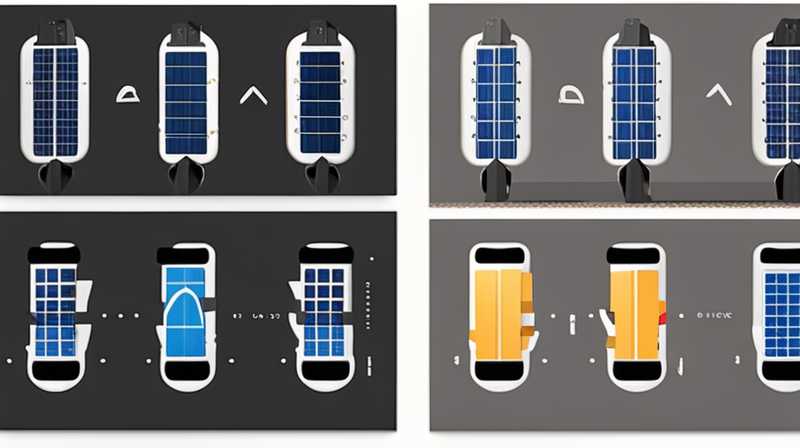

Examining the individual elements that comprise solar road studs reveals complexities in their design and engineering. These components can range from the solar cells, batteries, and LED lights to the protective covers and internal circuitry. Each part has been meticulously crafted to endure various environmental challenges, such as harsh weather conditions and physical stress from vehicular traffic.

The solar cells act as energy converters, transforming sunlight into electrical energy that charges an internal battery, typically lithium-ion. In optimal sunlight conditions, these batteries can charge completely, providing enough power to the LED lights for several hours of illumination during the night. This uninterrupted operation not only increases visibility for drivers but also enhances safety for pedestrians. Furthermore, quality solar road studs utilize durable materials for their housing and protective covers, ensuring that they remain intact despite exposure to elements like rain, snow, and extreme temperatures.

3. IMPORTANCE OF MAINTENANCE

Regular maintenance of solar road studs is essential for preserving their functionality and effectiveness. Maintenance encompasses various actions, including inspections, cleaning, and repairs, all of which contribute to the longevity of these crucial devices. A routine examination can help identify issues early on, such as misaligned studs, battery failures, or damaged covers, preventing complete system failures that might compromise road safety.

Cleaning is another vital aspect, as debris, dirt, and grime can obstruct the solar panels, hampering their ability to receive sunlight. This can lead to decreased charging efficiency, ultimately affecting the LED output. By ensuring the surface of solar road studs remains clear, one helps maximize the amount of solar energy harvested. In the case of damage or wear and tear, timely repairs can restore their functionality and extend their lifecycle, reducing the need for replacements and minimizing waste.

4. TOOLS REQUIRED FOR REMOVAL

Removing the cover of solar road studs requires specific tools to assist in the process. Screwdrivers, often flathead or Phillips, are commonly necessary to remove screws that may be securing the covers. Additionally, pry bars or plastic wedges might be beneficial for covers that are fitted tightly or glued into place, ensuring that removal does not lead to damage.

Having the right set of tools on hand will facilitate a smoother and more efficient removal process. It is also advisable to use gloves for protection during this operation, as cuts and scrapes can occur if one is not careful about the sharp edges of the stud or its cover. Furthermore, a multimeter can be employed afterward to assess the functionality of the internal components, ensuring that no damage has occurred during the removal procedure.

5. STEP-BY-STEP REMOVAL PROCESS

To efficiently and safely remove the cover from solar road studs, one must follow a systematic method that minimizes risks and ensures optimal results. Start by examining the solar road stud to identify how the cover is secured. If it contains screws, use the appropriate screwdriver to remove them gently. Be careful not to strip the heads of the screws, as this could complicate the removal.

Once all fasteners have been removed, or if it appears to be a pressure-fitted cover, use the pry bar or plastic wedge to carefully lift the edge of the cover. Using excessive force can break the cover or damage the stud itself, so it is crucial to apply steady, even pressure. As the cover begins to lift, work along the perimeter, ensuring that all areas are released. This step-by-step process will not only safeguard the structural integrity of all concerned components but will also streamline future maintenance procedures.

6. ADDRESSING COMMON ISSUES

During the removal of covers from solar road studs, various challenges may arise that require attention. One frequent issue is the occurrence of rusted screws or fasteners that may not easily turn or lift out. In such cases, utilizing penetrating oil can help loosen the screws, allowing for easier removal.

Another concern is the risk of cracking or damage as the cover is pried away. To mitigate this, it’s advantageous to deploy a methodical approach, applying pressure uniformly along the edges rather than concentrating on one spot alone. If the cover does become damaged, it’s essential to assess if it can be repaired or if a replacement is needed. Keeping spare covers or kits on hand can aid in swiftly addressing these situations, ensuring that the solar road stud remains operational without prolonged downtime.

7. PRACTICE SAFE PROCEDURES

Safety is a critical component when undertaking the removal of solar road stud covers, as improper handling can lead to injuries or further damage to the studs. Prior to beginning the process, ensure that the area surrounding the stud is clear of obstacles and traffic to prevent accidents.

Wearing suitable personal protective equipment, including gloves and safety glasses, can reduce the likelihood of injuries during this task. Moreover, it is advisable to inform other individuals in the vicinity of the operation being carried out. Identifying potential hazards and avoiding distractions significantly contribute to a safer working environment, ensuring that the removal process can proceed smoothly and efficiently.

8. FINAL INSPECTION AND MAINTENANCE

Upon successful removal of the cover, a thorough inspection of both the cover and the internal components of the solar road stud must be conducted. Look for signs of wear, corrosion, or damage to ensure functionality remains intact. Checking the battery levels and the condition of the solar cells is crucial, as this can determine whether any further action is warranted.

If damage is present, assess whether repairs can be made or if the replacement of parts is necessary. After any required cleaning and repairs, reattach the cover properly, ensuring all screws and fasteners are securely tightened. Following the maintenance and reinstallation process, conducting a test to verify functionality is essential for confirming effective illumination and performance, thus ensuring continued road safety.

FAQs

WHAT ARE SOLAR ROAD STUDS MADE OF?

The materials utilized in the manufacture of solar road studs contribute to their durability and functionality. Typically, they are constructed from high-impact resistant plastic, which protects against adverse weather and physical stress. Additionally, many also have aluminum or stainless steel components to enhance structural integrity. The internal parts consist of LED lights and lithium batteries, providing efficient illumination and longevity. These materials are specifically chosen to withstand harsh environmental conditions, ensuring that solar road studs maintain optimal performance over extended periods.

HOW LONG DO SOLAR ROAD STUDS LAST?

Solar road studs have a notable lifespan, which is influenced by several factors. On average, their longevity spans from 3 to 5 years depending on usage conditions, the quality of materials, and maintenance practices. Regular upkeep, such as cleaning and timely repairs, can extend their operational life by minimizing wear and tear. Furthermore, the efficiency of the solar cells and batteries plays a significant role; adequately charged batteries generally provide consistent brightness through various weather conditions. Overall, with optimal care, these devices can remain functional for an impressive duration.

CAN I INSTALL SOLAR ROAD STUDS MYSELF?

The installation of solar road studs can be performed by individuals with some expertise in outdoor electrical applications and safety protocols. However, to ensure proper placement and functionality, it is often recommended to consult with professionals. Factors to consider include ensuring adequate solar exposure for energy efficiency and adhering to local traffic regulations. If taking the DIY approach, familiarizing oneself with the installation guidelines and precautions is essential to minimize risks and errors. Ultimately, consulting experienced individuals can significantly enhance the chances of success in the implementation process.

The removal and maintenance of solar road studs require careful consideration and adherence to specific procedures. Understanding the importance of diligent inspections, practical tools, and safe practices can significantly enhance the efficacy of these devices in contributing to road safety. The intricate design of solar road studs, coupled with conscientious maintenance, leads to optimal functioning, ensuring clear visibility for drivers and pedestrians alike. Climate conditions, regular upkeep, and timely repairs will ultimately dictate the longevity and performance of such systems. Thus, being proactive in their care not only extends their operational life but also plays a vital role in safeguarding the communities they serve. Through a commitment to excellence in handling these essential road safety features, one can ensure that solar road studs remain a reliable asset in promoting safe navigation and reducing accidents on roadways.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-cover-of-solar-road-studs/