1. To effectively remove the copper head of a solar energy special tube, several steps must be followed: 1) Ensure safety protocols by wearing gloves and safety goggles, 2) Disconnect the solar tube from the system to prevent accidents, 3) Utilize appropriate tools such as a wrench or pliers to loosen the copper fittings, 4) Carefully detach the copper head while keeping the tube steady, 5) Inspect both the tube and copper head for any damage post-removal. Proper techniques and tools are critical for successful removal and prevention of injury or damage.

1. UNDERSTANDING THE STRUCTURE OF SOLAR ENERGY SPECIAL TUBES

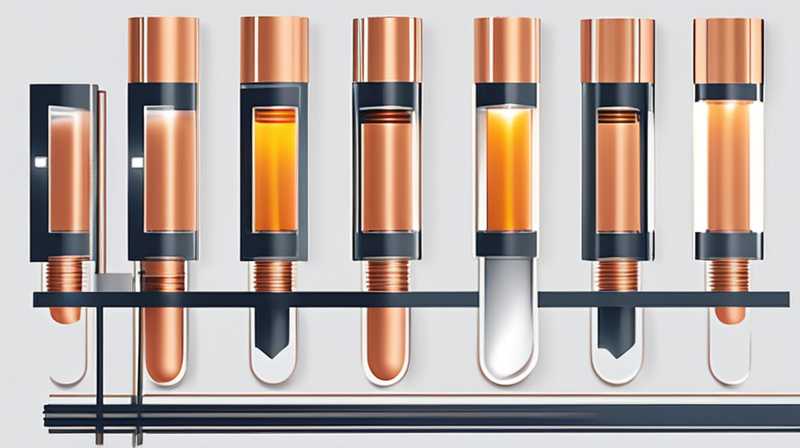

Solar energy special tubes, often employed in solar thermal systems, consist of various components that work synergistically to capture and convert sunlight into usable energy. The copper head is a crucial element, often designed to facilitate heat exchange efficiently. It allows the energy collected by the solar tube to transfer to a fluid, typically water, which is then used for heating purposes.

The construction of these tubes usually varies slightly depending on the manufacturer and application, but the core components remain similar. A robust glass envelope forms the outer layer, encapsulating an inner layer that is generally composed of selective coatings tailored for optimal solar absorption. The copper head attaches at one end of the tube, enhancing conductivity and ensuring that collected thermal energy is efficiently passed on.

In evaluating the structure, one must appreciate that the copper head is not just a functional component but also a critical point for maintenance. Understanding its role can ease the process of removal and replacement, should it become necessary. This knowledge facilitates a more adept handling during the disassembly process.

2. IMPORTANT TOOLS AND PREPARATION

Before embarking on the task of detaching the copper head from the solar energy special tube, having the right set of tools is imperative. The correct equipment not only aids in executing the task effectively but also ensures safety throughout the operation. Commonly required tools include adjustable wrenches, pliers, and sometimes a heat source if the fittings have become particularly stubborn due to corrosion or over-tightening.

Preparation is equally vital for a successful disassembly. Start by examining the system layout and identifying potential obstructions. It’s advisable to have a clean workspace, preferably with enough lighting to facilitate detailed inspection and manipulation of small components. Additionally, ensuring that you wear gloves and safety goggles can protect against accidental injuries that might arise from sharp edges or metal fragments.

Moreover, documenting the current setup can provide a reference point. Taking photos of the tube and copper head before beginning the removal process aids in reassembly and can be beneficial for troubleshooting. This preparatory step can save time and effort when reattaching or replacing the parts.

3. SAFETY CONSIDERATIONS

Prioritizing safety during the disassembly process cannot be overstated. Copper heads and solar tubes can contain residual fluids or pressures that pose hazards. As such, disconnecting the system from power sources and allowing it to cool down is a necessary step before starting. The inherent risks associated with disconnecting and handling these components underscore the importance of following safety protocols meticulously.

A well-organized approach can mitigate risks significantly. Using quality personal protective equipment (PPE) like gloves, goggles, and even dust masks can protect individuals from harmful substances or debris. It is crucial to inspect all tools before use to ensure they are in good working condition, as malfunctioning equipment can lead to accidents.

In case of injury or an unexpected event, having a first-aid kit nearby can provide immediate aid. Understanding the potential risks associated with the removal of the copper head allows for more informed decision-making, ultimately fostering a safer work environment.

4. DISCONNECTING THE SOLAR TUBE

Once the necessary preparations have been made and safety measures are in place, the next step involves disconnecting the solar tube from the overarching system. Start by turning off any pumps or electronic valves associated with the solar energy system to ensure that no fluid can accidentally leak during the process. It’s imperative to have a contingency plan ready should any unexpected issues arise during disconnection.

Gently loosening the fittings with an adjustable wrench is advisable. Applying even pressure ensures that no damage occurs to the copper head or the treads on the solar tube. If the fittings resist initial turns, utilizing penetrating oil may assist in breaking the bond created by corrosion. Patience is critical during this phase, as rushing could risk damaging the copper head or the threading on the tube.

When adequately loosened, carefully pull the tube away from the copper head, maintaining a firm grip. This action should be done with consideration to not introduce any unnecessary strain to connected parts, as this could result in further complications. The disconnection procedure lays the groundwork for the subsequent removal of the copper head, which can now be executed more straightforwardly.

5. REMOVING THE COPPER HEAD

Having successfully disconnected the solar tube, removing the copper head is the next endeavor. At this stage, one must ensure the area is free of any debris or obstacles that could interfere. First, assess the condition of the copper head and the surrounding area for any signs of damage or corrosion that could have developed over time, as this might require additional steps to handle properly.

Using pliers, grasp the copper head securely and gently twist while applying constant tension to pull it away from the base. It is essential to maintain control during this process, as any sudden movements can lead to breaks or cracks in either the copper head or the solar tube. Should the copper head remain tight, carefully applying heat with a heat gun may loosen any tight fittings caused by thermal expansion.

As the copper head detaches, one should continue monitoring for any unusual signs, such as fluid leakage or minor fractures within the tubing. Thoroughly inspecting both components post-removal will further inform any future actions regarding the installation of a new or replacement head.

6. POST-REMOVAL INSPECTION AND CLEANUP

After successfully detaching the copper head, it is critical to inspect both components thoroughly. This inspection serves multiple purposes, including identifying any wear or damage that may impact performance. For the copper head, examining the welding points and the integrity of the copper material is essential. Look for signs of corrosion or significant wear that might indicate the need for replacements ahead of reassembly.

Simultaneously, the tube should be assessed for any obstructions or residue that could hinder a proper seal upon reinstallation. Cleaning any applicable areas ensures a smooth reattachment process in future steps. Use a wet cloth to wipe down the area and remove any dust or debris, which might have accumulated during the disconnection and removal processes.

Finally, the workspace must be properly tidied up to prevent any stray tools or components from causing accidents later. Ensuring everything is in order minimizes risks and sets a professional standard for future maintenance or installations related to the solar energy system. This thorough approach fosters clarity and prepares one for the reinstallation phase ahead.

7. REINSTALLATION OF THE COPPER HEAD (IF NECESSARY)

Should the replacement of the copper head become necessary, preparing for reinstallation is equally as vital as its removal. Ensure that all materials and measurements align with the new copper head’s specifications. Compatibility with existing components ensures no alterations are required during reattachment, thus streamlining the process.

Before reinstallation, applying sealant to the threads of the copper head can enhance the connection and prevent leaks. Properly tightening the fittings while ensuring that they align is essential for achieving a secure connection. Gradually reattach the copper head, using adjustable wrenches to achieve the necessary torque without overtightening. It’s beneficial to periodically check for any signs of leakage during this process, as it allows for prompt adjustments.

Once connection is secured, reattach the solar tube carefully, following the previous documentation or photographs taken before disassembly. This final phase culminates in ensuring that all components are aligned and secure. Following the installation, it’s highly recommended to test the system by activating it and checking for leaks or performance inconsistencies, ensuring everything functions optimally.

8. COMMON CHALLENGES AND TROUBLESHOOTING

The process of removing the copper head from a solar energy special tube is fraught with potential challenges. One issue that often arises is the over-tightening of the fittings, which can lead to significant difficulties in disassembly. Over time, salt buildup or corrosion may also result in the copper head becoming firmly affixed to the tube. In such cases, patience and gentle application of heat can assist in loosening fittings without causing damage.

Another common challenge lies in the condition of the tube itself. If cracks or signs of wear are noticed during inspection, replacement may be necessary. This could complicate matters if one considers factors such as matching specifications or finding suitable replacement parts. Thorough research and communication with suppliers can alleviate some of these concerns, ensuring that appropriate materials are sourced ahead of time.

Furthermore, users should watch for signs of leaks after reinstallation, as this indicates improper fit or wear. Addressing these issues swiftly is crucial for maintaining the efficiency of the solar energy system overall.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS DO I NEED FOR REMOVING THE COPPER HEAD?

To remove the copper head from a solar energy special tube, several tools prove essential. Begin with an adjustable wrench, typically the primary tool for loosening and removing fittings. Pliers can help maintain a secure grip on the copper head while twisting and pulling for better control during disconnection. In cases where parts may be tightly secured due to rust or corrosion, a heat source might be beneficial as well, employing a heat gun to loosen stubborn fittings. Having safety goggles and gloves to protect against potential injuries is also recommended. Ensuring that all tools are functional before starting the process can significantly reduce risks and enhance efficiency.

HOW CAN I PREVENT DAMAGE WHEN REMOVING THE COPPER HEAD?

To prevent damage to the copper head and surrounding components during removal, several strategies should be employed. First, ensure that the workspace is organized and clean, minimizing hazards while maneuvering tools. Carefully assess the connection points to identify any signs of corrosion, which may require additional treatment before attempting disconnection. Using a gentle yet consistent force when loosening fittings significantly reduces the risk of breaking components. If a fitting feels resistant, applying penetrating oil and waiting can help. Importantly, keeping a steady grip throughout the process ensures greater control. Lastly, maintaining patience and attentiveness can go a long way in avoiding mistakes that often lead to damage.

WHAT SHOULD I DO IF THE COPPER HEAD IS STUCK?

If the copper head is stubborn and resists removal, don’t panic, as several solutions may help. First, confirm that all fittings are correctly loosened. If the head remains fixed, applying a penetrating oil to the threading can sometimes aid in breaking any bonding formed by oxidation. Allowing the oil to sit for several minutes usually yields the best results. If rust or corrosion is severe, gently applying heat to the copper head can expand metals slightly and help loosen it. It’s crucial to use heat carefully; avoid overheating, which can damage surrounding components. If all else fails, consulting a professional is advisable to avoid causing harm to the solar tube or system during removal.

In summary, effectively removing the copper head from a solar energy special tube involves a meticulous approach. Adhere strictly to safety protocols, ensure proper tool usage, and approach disassembly patiently. Engage in thorough inspections and cleanups post-removal to prepare for either replacement or reattachment. The tasks require concentration and care, as the components play critical roles in the solar system’s performance. Following a systematic procedure lessens challenges, while a clear understanding of tools and techniques leads to successful maintenance of solar energy tubes. Maneuvering through the sequence with accurate knowledge not only guarantees efficiency but also promotes the longevity of the solar energy system as a whole. As individuals navigate this process, preparedness and professionalism create a conducive environment for achieving effective results with solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-copper-head-of-solar-energy-special-tube/