How to put the solar sensor line through the pipe

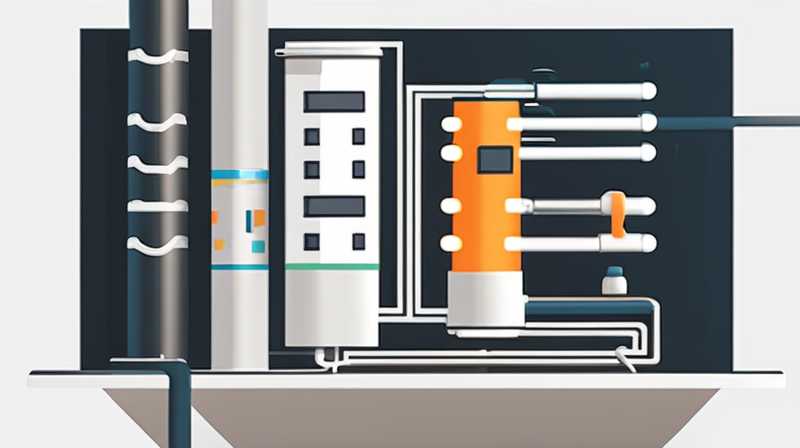

1. Incorporate the solar sensor line into a piping system, utilizing appropriate tools and techniques, ensuring secure and efficient installation. Critical aspects include 1) selecting the right type of pipe, 2) preparing the solar sensor line properly, 3) using efficient methods for threading the line, and 4) ensuring waterproof and dustproof connections. A detailed approach to each of these elements ensures that the solar sensor line functions effectively while remaining durable against environmental factors. For instance, choosing a flexible pipe made from resilient materials can facilitate easier installation while providing sufficient protection for the sensor line itself against potential damage. Connecting the solar sensor line securely is vital; failure to do so might result in malfunctioning sensors, thereby compromising system efficiency.

1. SELECTING APPROPRIATE PIPE MATERIALS

The choice of piping material stands as a fundamental factor in creating a robust installation for the solar sensor line. Generally, pipes can range from PVC and polyethylene to metal options like copper or steel. Each material presents unique characteristics that can influence both installation and long-term performance.

For instance, PVC pipes are lightweight and resistant to corrosion, making them an ideal choice for outdoor setups. They are also relatively easy to handle and cut, allowing for seamless installation procedures. On the contrary, metal pipes offer enhanced durability and resilience against physical impacts but can be more cumbersome to manipulate. Hence, understanding the application and environmental conditions will greatly aid in selecting the correct pipe type.

Additionally, the diameter of the pipe must align with the dimensions of the solar sensor line. A snug fit is crucial; too much slack can lead to kinks or bends that might impede sensor functionality. Using a pipe with a diameter that accommodates the solar sensor line while allowing for effective insulation is paramount to achieving optimal performance. Conducting a diagrammatic assessment of the installation area can assist in calculating the necessary measurements.

2. PREPARATION OF THE SOLAR SENSOR LINE

Before integrating the solar sensor line into the piping system, the line itself undergoes critical preparatory steps to maximize its efficiency. Proper preparation entails removing any protective sheathing, ensuring that the wire strands are intact, and inspecting the line for potential damage. Thoroughly cleaning the solar sensor line to eliminate dust and moisture is imperative, as contaminants may lead to connection failures later.

Moreover, applying a protective sheath or insulation is advisable. This extra layer safeguards the line against physical abrasions and environmental factors such as rain or dust. Additionally, using a sealant can prevent the entry of moisture, which could cause corrosion or short-circuiting. Each precaution taken at this stage enhances the longevity and function of the sensor line once installed.

Following the preparatory phase, testing connections with a multimeter prior to installation ensures that they function as intended. Ensuring that the sensor line is operational guarantees that the entire system will perform efficiently once installed within the chosen piping.

3. THREADING THE SENSOR LINE THROUGH THE PIPE

Once the materials have been selected, and the solar sensor line prepared, the actual process of threading the sensor through the pipe can commence. The method adopted can vary based on the configuration of the installation site and the specific characteristics of both the sensor line and pipe. Using a fish tape is one method that stands out for its efficiency. This tool helps guide and pull the sensor line through the pipe with minimal risk of damage.

To employ this method effectively, one starts by feeding one end of the fish tape into the pipe, gradually allowing it to progress until it exits at the other end. It is crucial to lay the sensor line parallel to the fish tape to facilitate smooth movement through the pipe. Once the fish tape reaches the opposite end, carefully tethering the sensor line to it allows for a seamless pull.

Alternatively, utilizing lubricants can further enhance the ease of threading. A specialized lubricant reduces friction and helps the sensor line glide through the pipe more easily. However, care must be taken to ensure that the lubricant does not interfere with the sensor’s operational capabilities; thus, selecting the appropriate product is vital. Proper execution of this phase ensures a successful threading process, contributing to the overall durability and efficiency of the installation.

4. ENSURING PROPER SEALING AND CONNECTIONS

Achieving a meticulous sealing around the entry and exit points of the pipe where the sensor line emerges is fundamental for maintaining system integrity. Using high-quality waterproof sealants is critical to prevent moisture infiltration, which can adversely affect sensor functionality. The sealing process should encompass all potential ingress points and ensure airtight fittings.

Consideration should be given to where the sensor line enters and exits the piping system; these locations require added protection. Fitting the pipe with grommets or bushings can enhance sealing and protect against wear and tear from friction caused by wind or vibration.

Moreover, performing regular maintenance checks post-installation is essential. Periodic inspections help identify any wear on seals, test the operational integrity of the sensor line, and remedy any issues before they escalate into major problems. Comprehensive care extends the lifespan and reliability of the solar sensor line, ensuring its continuous performance for many years.

5. INSULATION AND ENVIRONMENTAL PROTECTION

The environmental factors impacting the solar sensor line must not be overlooked. Appropriate insulation represents a crucial consideration, especially if the installation occurs in extreme weather conditions. Using insulating materials can provide an extra layer of protection against temperature fluctuations, preventing hardware failure due to overheating or freezing.

It is advisable to select insulation materials designed specifically for outdoor use. These materials withstand UV rays and do not degrade quickly under harsh conditions, representing an ideal choice for prolonged exposure. Additionally, securing the insulated sensors in a manner that prevents wind or rain interference can enhance their operational lifespan. Revisiting the overall design and structure of the piping contributes valuable protection to the solar sensor lines.

Implementing protective measures involves not only insulation but also strategic placement of the pipes themselves. Positioning pipes in shaded areas, where feasible, lessens exposure to direct sunlight, helping reduce thermal stress on both the pipe and sensor line.

FAQs

WHAT TO CONSIDER BEFORE INSTALLING A SOLAR SENSOR LINE?

Before commencing installation, several key factors should be taken into account. Firstly, evaluate the intended environment for deployment, as this dictates the materials and methods that will be most effective. For example, installations in high UV exposure areas would benefit from UV-resistant piping and insulation materials. Secondly, assess the existing infrastructure and piping layout, ensuring compatibility with the solar sensor line. Properly measuring the dimensions of both the sensor line and piping beforehand helps avoid complications during threading. Additionally, familiarizing oneself with local codes and regulations concerning electrical installations can prevent legal issues and ensure safety compliance.

WHAT TO AVOID WHEN INSTALLING A SOLAR SENSOR LINE?

Certain common pitfalls should be avoided during installation to ensure optimal performance of the solar sensor line. One significant mistake is neglecting to secure connections adequately; loose connections can lead to potential malfunctions or signal loss. Another factor pertains to inadequate insulation—overlooking this can expose the line to temperature extremes that may cause failures. Also, avoid using incompatible materials, as this can contribute to corrosion or degradation. For example, pairing metal with dissimilar metals can accelerate electrolysis deterioration. Careful planning and thorough research reduce risks and enhance the effectiveness of installations.

HOW OFTEN SHOULD THE SYSTEM BE MAINTAINED?

Routine maintenance is essential in preserving the integrity and functionality of the solar sensor line. Ideally, conducting inspections biannually helps identify wear and tear, ensuring any issues are addressed promptly. Focus on checking connections, seals, and insulation, looking for signs of degradation or moisture damage. Paying attention post-storm events is particularly critical, as severe weather can disrupt sensor functionality. Additionally, make it a practice to clean and clear the installation area, removing debris that may impede sensor performance over time. Implementing consistent maintenance strategies effectively extends the lifespan of the solar sensor line.

The diligent installation of the solar sensor line through the piping system encapsulates multifaceted considerations necessary for optimal performance. Successful execution hinges on the choices made regarding materials, the preparation of the sensor line, and effective threading methods. Furthermore, ensuring secure sealing and proper insulation protects the line from environmental adversities, thereby enhancing its operational lifespan. Gradual adherence to each outlined process, alongside regular maintenance routines, promotes the resilience and efficiency of the solar sensor system.

The importance of integrity in these systems cannot be overstated; they are often critical for generating energy or monitoring important data. Thus, investing time and resources during the installation process pays dividends in reliability, functionality, and system efficiency. Properly executed installations of solar sensor lines can significantly contribute to sustainability goals and energy conservation efforts. Engaging in continual learning regarding advancements in sensor technology and installation methods allows for optimized outcomes in future projects.

Through diligence, awareness, and proactive measures, one can ensure that the integration of solar sensors into piping systems is a seamless and fruitful endeavor.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-put-the-solar-sensor-line-through-the-pipe/