To effectively process solar cylinders, one must follow a structured series of steps that encompass various technical and operational aspects involved in solar energy systems. 1. Understanding the components of solar cylinders, 2. Selecting appropriate materials for manufacturing, 3. Ensuring optimal installation methods, 4. Maintenance strategies for longevity. The processing of solar cylinders involves intricate engineering and technology that maximize energy absorption and efficiency.

Understanding the Components of Solar Cylinders

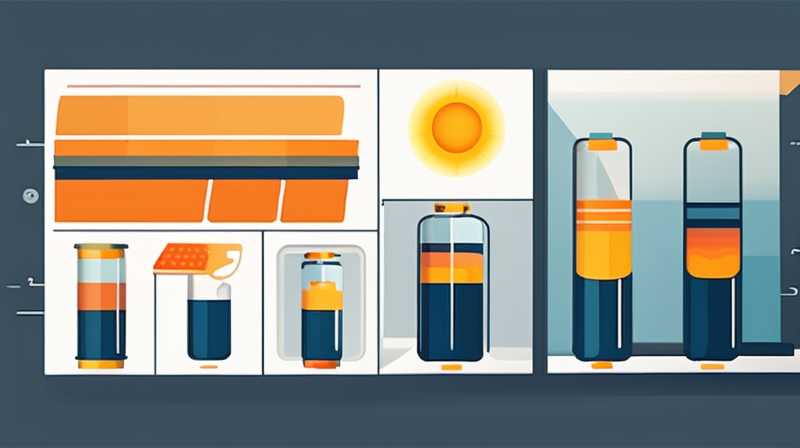

Solar cylinders, typically referred to as solar thermal collectors, play an essential role in harnessing solar energy. They are designed to collect sunlight and convert it into usable heat. The main components of solar cylinders include the collector plate, insulated casing, and a working fluid that circulates through the system. The collector plate, often made of a metal material like copper or aluminum, is coated with a selective surface that enhances its ability to absorb sunlight. This enables conversion of solar radiation into heat effectively.

The insulating layer is crucial for preventing heat loss, ensuring that the energy captured is not wasted. The choice of materials for the casing and insulation directly affects the system’s efficiency and longevity. It is imperative to select materials that can withstand varying weather conditions as well as temperature fluctuations. Proper understanding of these elements not only facilitates efficient energy conversion but also informs decisions on design and functionality.

Selecting Appropriate Materials for Manufacturing

Selecting quality materials is one of the most important considerations in manufacturing solar cylinders. Materials such as tempered glass, which allows for optimal sunlight transmission while providing structural integrity, are typically used for the covering. Transparent covers also serve to protect the collector plate from environmental elements while still enabling sunlight to penetrate.

Furthermore, insulation materials like fibreglass or polyurethane are vital in minimizing heat loss. They are installed around the cylinder to create a barrier against heat transfer to the outside environment. The quality of these materials impacts not only the efficiency of solar collectors but also their durability and maintenance needs. Choosing appropriate materials involves assessing both the thermal performance and the resilience of the components, ensuring that they can handle the specific conditions in their intended installation environment.

Ensuring Optimal Installation Methods

Achieving the best performance from solar cylinders substantially depends on the chosen installation method. Solar collectors should ideally be positioned at an angle that maximizes exposure to the sun’s rays, which varies by geographic location. This positioning also depends on the seasonal changes in solar altitude. Accurate calculation of these angles typically involves understanding solar paths and utilizing tools that help in analyzing shading effects from nearby structures.

Additionally, installation should take into consideration the structural integrity of rooftops or mountings. With solar cylinder systems, ensuring that they are securely fastened and capable of bearing load is essential, especially in regions prone to strong winds or heavy precipitation. Effective installation also includes properly connecting plumbing or fluid channels that enable efficient circulation of the working fluid. The overall effectiveness and efficiency of solar thermal systems hinge on rigorous planning and execution during the installation phase.

Maintenance Strategies for Longevity

Ongoing maintenance is a crucial aspect to ensure solar cylinders continue to operate effectively, promoting a longer lifespan. Much like any mechanical or electronic equipment, regular inspections and upkeep play a fundamental role. Routine checks for leaks, corrosion, or debris can help maintain optimal performance. Any accumulation of dirt and silt on collector plates should be cleaned regularly to maximize sunlight absorption.

Furthermore, periodic evaluations of system fluid levels and quality are vital. In many cases, fluids used in solar cylinder systems can degrade over time, leading to inefficiencies. Conversely, the presence of air in the system or improper fluid flow can also contribute to diminished heat transfer. Employing a preventive maintenance schedule not only enhances efficiency but can significantly reduce the risk of costly repairs or replacements. Adopting these strategies fosters energy sustainability and reinforces the longevity of solar systems.

FREQUENTLY ASKED QUESTIONS

1. WHAT MATERIALS ARE BEST FOR SOLAR CYLINDERS?

Selecting materials for solar cylinders is crucial for efficiency and durability. Commonly used materials include tempered glass for covering, copper for the collector plate due to its excellent heat conductivity, and insulation materials such as rigid foam or fibreglass. The glass must permit high sunlight transmission while being resistant to weather conditions; hence, tempered glass is generally preferred. The collector plate must feature a selective coating that enhances absorption while minimizing radiative heat loss. For insulation, it is important to choose materials that can withstand varying climates. These materials overall contribute significantly to the performance and lifecycle of solar cylinders, making careful selection necessary for achieving optimal energy output.

2. HOW DOES INSTALLATION AFFECT SOLAR CYLINDERS’ PERFORMANCE?

The effectiveness of solar cylinders is heavily influenced by installation methods. Proper orientation and tilt angles play essential roles in maximizing solar exposure throughout the year. Each geographic area has specific optimal angles that should be calculated prior to setting up the units. Additionally, security in mounting the cylinders is vital, particularly in storm-prone areas, to mitigate risks of displacement or damage. Incorrect installation can lead to shading issues, inefficient energy collection, and even structural instability. Ensuring correct installation practices brings about not only improved performance but also long-term savings by reducing maintenance requirements and enhancing system reliability.

3. WHAT MAINTENANCE IS REQUIRED FOR SOLAR CYLINDERS?

Ongoing care and upkeep of solar cylinders are pivotal for maintaining efficiency and longevity. Routine inspections should encompass checks for leaks, corrosion, and blockages in fluid pathways. Cleaning collector plates regularly is essential, as dust and debris can significantly hinder performance by blocking sunlight. In addition, evaluating the quality of the working fluid ensures it is functioning properly and free of contaminants. The longevity of solar systems is enhanced through preventative maintenance rather than reactive measures, ultimately leading to higher energy efficiency and lower lifetime costs. Engaging professional services for thorough inspections is also advisable to address complex issues that could negatively impact performance.

Bold conclusions emerge from a thorough examination of solar cylinder processing, highlighting multiple crucial points and considerations. The role of materials selection cannot be overstated, as high-quality components directly correlate with performance and durability. Understanding the operational framework inclusive of installation methodologies significantly impacts overall efficiency, which mandates careful planning. Additionally, adopting a routine maintenance approach assures longevity, ensuring systems operate at maximum capabilities and reducing operational costs. Bringing together these components creates a well-rounded approach to processing solar cylinders, aligning with sustainability goals while advancing technology integration in renewable energy applications.

The continued advancement of solar technology urges stakeholders to prioritize effective strategies in system setup and maintenance. As the world leans increasingly towards energy alternatives, understanding how to process solar cylinders effectively becomes pivotal. This not only promotes energy efficiency but also bolsters the transition toward sustainable energy practices, ultimately benefiting both the environment and economic landscapes on a global scale.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-process-solar-cylinders/