To effectively press the old solar sealing ring, one must follow a systematic approach involving several critical aspects: 1. Understanding the Components, 2. Tools and Equipment Required, 3. Step-by-Step Procedure, 4. Safety Precautions, 5. Maintenance Tips. Properly executing this process ensures the longevity of the solar sealing ring, minimizes leaks, and maintains the overarching functionality of solar systems. Knowledge of various components and their compatibility plays a significant role. Elaboration on Understanding the Components: It is essential to identify the sealing ring and recognize its purpose in preventing moisture intrusion and facilitating energy efficiency. Each aspect of the sealing system contributes to overall performance, thereby necessitating careful handling.

1. UNDERSTANDING THE COMPONENTS

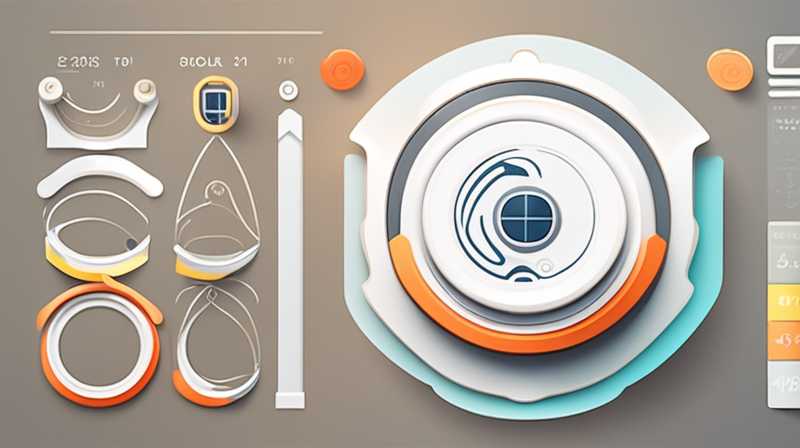

The solar sealing ring functions as a vital component in numerous solar photovoltaic and thermal systems. It forms a tight barrier between the solar collector and the environment, preventing water and air infiltration. When examining these components, it’s crucial to distinguish various elements involved in the sealing system, such as the gasket, pressure plates, and the frame. Understanding these components aids in assessing their condition and identifying when pressing the old sealing ring is necessary.

In many cases, the sealing effectiveness deteriorates due to environmental wear, chemical exposure, or mechanical fatigue. This degradation can lead to compromised efficiency. Before engaging in the pressing procedure, one should evaluate the current condition of the sealing ring thoroughly. It is advisable to inspect for any visible cracks, deformities, or signs of wear that could impact the ring’s ability to maintain a secure seal. Proper assessment aids in determining whether the existing ring can be pressed back into shape or if replacement is the most feasible option.

2. TOOLS AND EQUIPMENT REQUIRED

Engaging in the pressing of an old solar sealing ring necessitates a careful selection of tools and equipment. A meticulous approach ensures the successful execution of the task while minimizing potential damage to the ring or surrounding components. Essential tools typically include a hydraulic press, clamps, lubricant, and measuring instruments. Each of these items plays a distinct role in the process.

The hydraulic press is an indispensable machine for applying uniform pressure to the sealing ring, thereby allowing for effective reshaping without compromising its integrity. Clamps serve to stabilize the ring during the pressing process, aligning it correctly to avoid misalignments or unwanted bends. Lubricants enhance the ease of operation, ensuring smooth movement of the components, while measuring instruments provide necessary data, assisting in achieving precise dimensions necessary for an effective seal.

3. STEP-BY-STEP PROCEDURE

Executing the pressing of the old solar sealing ring follows a detailed step-by-step methodology ensuring an organized approach. The first stage involves removing the sealing ring from its housing, ensuring that all screws, bolts, or other retention mechanisms are properly disengaged. This facilitate the assessment of its condition and prepares it for pressing.

Subsequently, the sealing ring is cleaned thoroughly to remove dirt, debris, or old sealant that may affect the pressing quality. After cleaning, the inspection stage follows, where the operator looks for cracks, deformities, or any indications that the ring may have lost its structural integrity. If such issues arise, deciding whether the ring is pressable or requires replacement is imperative. Assuming the ring is intact, it is then securely positioned within the hydraulic press.

Applying pressure comes next, where a slow and steady approach is vital. The operator must monitor the deformation carefully, adjusting as necessary. Attention must be given to prevent over-compression, which could damage the ring beyond repair. Once the desired shape is achieved, the ring should be examined for uniformity and stability.

Post-pressing processes may include coating with sealant for added durability and blending it back into its original installation area. Ensuring the outer surfaces are clean from excess material allows for better adhesion, significantly affecting its functionality.

4. SAFETY PRECAUTIONS

Safety remains an integral part of the pressing procedure, as improper handling can result in injuries or equipment damage. Operators should wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and sturdy footwear, to safeguard against potential hazards. Familiarity with the hydraulic press’s operational guidelines is crucial to operating the equipment safely; users must follow manufacturer specifications and practices modelled on industry standards.

Secure the working area by removing any unnecessary objects or hazards that could pose risks during the procedure. Prior to engaging the hydraulic press, ensure all tools and equipment are in good condition, particularly the clamps and the hydraulic system. Regular maintenance checks on equipment can prevent malfunctions during a critical process.

Awareness of pinch points, or areas where body parts could be at risk while using the hydraulic press, is paramount. It’s recommended to have a second individual present during the pressing to provide assistance or apply emergency stops if necessary. A well-organized approach focusing on safety significantly mitigates risks and fosters a productive working environment.

5. MAINTENANCE TIPS

Maintaining sealing rings after the pressing process ensures optimal performance in the long term. Individuals should routinely inspect the integrity of the sealing ring at defined intervals to catch any early signs of wear. Regular cleaning to remove environmental debris keeps the sealing surfaces free from substances that could degrade adhesion. Additionally, applying non-corrosive lubricants to moving parts can help maintain function and reduce wear over time.

It is also beneficial to keep moisture levels in an optimal range around the solar unit as excess moisture can lead to accelerated degradation and rusting of components. Implementing protective coatings or membranes can enhance resistance against elements, thus prolonging the lifespan of the sealing ring and associated mechanisms. Finally, maintaining accurate records of inspections, repairs, and maintenance activities assists in tracking the performance history of the sealing system, allowing for informed decisions regarding future maintenance activities or replacement needs.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR SEALING RING?

A solar sealing ring acts as a critical barrier in solar systems, preventing water and air from infiltrating the collection area. This component ensures that the overall efficiency and functionality of the solar unit remain intact. Typically made from durable materials, the sealing ring must withstand environmental stresses, such as temperature fluctuations, UV radiation, and exposure to various weather elements. Regular assessment of the sealing ring is essential, as wear and tear can lead to leaks, reducing the overall energy collection efficiency of the solar unit. Maintaining its integrity through procedures like pressing is integral to the longevity and performance of solar technologies. Operators should be aware of the particular specifications for their systems to ensure that the sealing ring is compatible with the intended application, as improper selections can lead to performance issues.

HOW OFTEN SHOULD I PRESS A SOLAR SEALING RING?

The frequency of pressing a solar sealing ring is typically contingent upon various factors such as environmental conditions, the frequency of exposure to extreme temperatures, and the specific type of materials used in crafting the ring. Generally, a thorough inspection should occur at least once a year, while pressing may be conducted when signs of wear are evident, such as cracks or distortions. For units exposed to harsher conditions, more frequent assessments may be warranted. Operators should aim to establish a routine maintenance schedule based on specific environmental factors, user experiences, and the manufacturer’s recommendations. Staying vigilant with maintenance ensures the sealing ring functions efficiently, directly impacting the solar system’s productivity and efficacy. Proactive care and addressing issues promptly can mitigate costly repairs and replacements, thus extending the operational life of solar installations.

IS IT BETTER TO REPLACE OR PRESS A SOLAR SEALING RING?

The decision to replace or press a solar sealing ring often entails a thoughtful evaluation of several aspects. If the sealing ring exhibits minor deformities or no significant material degradation, pressing can be a practical solution to restore functionality. However, if assessments reveal considerable wear, deep cracks, or major structural integrity issues, replacement becomes preferable. Replacing offers a higher assurance of performance, guaranteeing optimal sealing capabilities and energy efficiency. Operators should weigh the costs associated with both options, factoring in labor, potential downtime, and the long-term performance outcomes of pressed versus replaced components. In many cases, the original manufacturer’s guidelines can offer valuable insights regarding the longevity and operability of materials, guiding decisions more effectively. Prioritizing system performance and efficiency must guide approaches to maintenance, ensuring that whether pressed or replaced, the sealing ring performs its intended role effectively.

Effectively executing the pressing of an old solar sealing ring significantly enhances a solar system’s overall performance and longevity. Comprehensive understanding coupled with meticulous attention to detail and maintenance practices can save considerable time and resources. Utilizing the right tools, adhering to systematic procedures, and prioritizing safety constitutes a professional approach that will deliver sustained results in solar energy applications. Proper care and management of sealing rings forge a long-term path toward efficiency, utility, and reliable energy harvesting from solar technologies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-press-the-old-solar-sealing-ring/