To effectively paste solar lamp beads, several steps can be undertaken, focusing on 1. Proper surface preparation, 2. Selecting the right adhesive, 3. Application techniques, and 4. Curing and finishing touches. Preparing the surface thoroughly ensures that the beads adhere properly, while choosing an appropriate adhesive guarantees durability in various weather conditions. Applying the adhesive requires precision to avoid mess and enhance the visual appeal. Finally, allowing adequate time for the adhesive to cure ensures a long-lasting bond and optimal performance of the solar lamp. Among these steps, focusing on proper surface preparation is crucial, as any contaminants or dirt can drastically reduce the effectiveness of the adhesion, leading to premature failure of the solar lamp beads.

1. PROPER SURFACE PREPARATION

Preparing surfaces for attaching solar lamp beads involves thorough cleaning and priming. Dust, grease, and other contaminants can prevent optimal adhesion, resulting in a weak bond between the adhesive and the surfaces being used. Begin by selecting an appropriate cleaning method for the specific materials involved, which can vary across glass, plastic, and metal surfaces. For instance, a mild soap solution may suffice for glass, while plastic might require a stronger solvent such as isopropyl alcohol to eliminate oils and other residues.

After cleaning, evaluate the surface texture. Smooth surfaces may require additional effort to ensure that the adhesive grips adequately. Sanding the surface lightly with fine-grit sandpaper can increase the contact area for the adhesive, bolstering its hold. Following this, rinsing with water and allowing the area to dry completely will remove any remnants from the sanding process, leading to a pristine surface for adhesion.

2. SELECTING THE RIGHT ADHESIVE

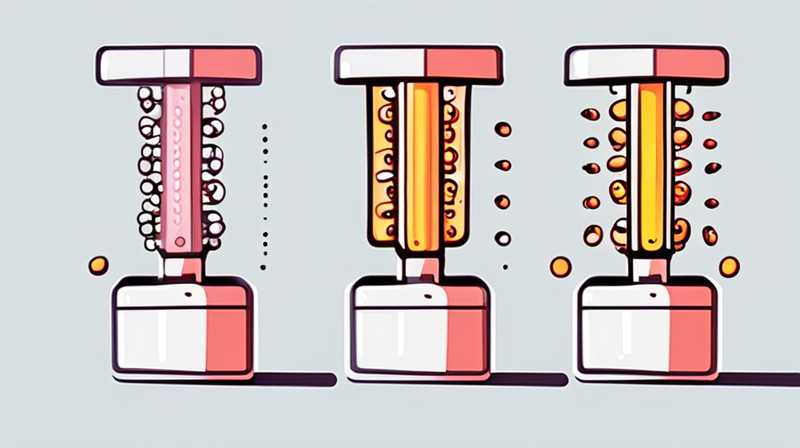

Choosing an appropriate adhesive is paramount for the durability and longevity of the solar lamp beads. Different adhesives possess varying qualities that make them suitable for specific applications. For instance, silicone adhesive is favored for its weatherproof and flexible properties. It can withstand fluctuations in temperature, humidity, and exposure to sunlight without degrading. Conversely, cyanoacrylate adhesives, commonly known as superglue, bond quickly but may become brittle over time, making them less ideal for outdoor applications.

Consider the material of the solar lamp beads and the surrounding surface when selecting an adhesive. For materials that expand and contract with temperature changes, a flexible adhesive is beneficial, providing stability without cracking. Additionally, water-resistant properties are crucial if the lamp will be exposed to rain or moisture. Ensuring compatibility between the adhesive and both the beads and mounting surface can help in achieving a long-lasting bond, reducing the risk of future repairs.

3. APPLICATION TECHNIQUES

The method of applying adhesive significantly affects the ultimate strength and appearance of the bond. When applying adhesive to solar lamp beads, precision is key. Using a syringe or a fine-tip applicator can help control the amount of adhesive dispensed, minimizing excess that might ooze from the edges. Avoiding mess during the application process is crucial, as any adhesive that gets onto unwanted areas can detract from the overall aesthetic of the lamp.

Follow the manufacturer’s recommendations regarding curing time and pressure application. Some adhesives require clamping or holding the pieces together for a defined period, which ensures a firm bond is established before the adhesive begins to cure. Additionally, working in a well-ventilated area can help minimize exposure to fumes and should be considered when applying certain types of adhesives. Proper application techniques not only enhance the aesthetic appeal of the project but also improve the overall effectiveness of the bond, ensuring that the beads stay securely in place over time.

4. CURING AND FINISHING TOUCHES

Once the adhesive has been applied, allowing sufficient time for it to cure is essential. Each adhesive type has specific curing times that impact the bond’s strength and durability. While some may only require a few hours, others may need 24 hours or longer to include moisture and temperature factors that influence curing. Avoiding the temptation to rush this process will lead to more successful results. Monitoring the environmental conditions—such as humidity and temperature—can also play a crucial role in the curing process.

After the adhesive has fully set, inspect the bond for any imperfections or areas where excess adhesive may have leaked out. Carefully trimming away excess adhesive can enhance the aesthetics, giving a clean and polished appearance. If necessary, applying a clear sealant over the joint may provide additional weatherproofing and bolster longevity. Ensuring that all preparations, applications, and finishes are completed diligently will lead to a reliable and visually appealing installation of solar lamp beads.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF ADHESIVE IS BEST FOR SOLAR LAMP BEADS?

Selecting the most suitable adhesive for solar lamp beads can significantly impact their performance and longevity. Silicone adhesive is often preferred for outdoor applications due to its excellent weather resistance, flexibility to accommodate temperature fluctuations, and ability to bond various materials such as glass, metal, or plastic. This type of adhesive forms a strong bond while remaining flexible enough to absorb impacts and shocks, which can occur through seasonal changes or accidental contact. However, cycloaliphatic epoxy adhesives also provide exceptional strength and durability, making them another favorable choice for permanent installations.

It’s essential to consider the intended location and environmental conditions where the solar lamp will be installed. For areas with high moisture exposure or extreme temperatures, an adhesive that offers prolonged durability and low vulnerability to degradation due to sun exposure is vital. Review the product details to ensure compatibility with the materials and environmental conditions for a successful outcome. Ultimately, selecting the right adhesive ensures that solar lamp beads remain secure and attached, contributing to the efficient operation of the lamp throughout its lifespan.

HOW CAN I PREVENT SOLAR LAMP BEADS FROM FALLING OFF?

Preventing the detachment of solar lamp beads involves a combination of effective preparation, adhesive choice, and application techniques. Initially, ensuring that the surfaces are thoroughly cleaned and devoid of dust or oils is crucial. Without proper surface preparation, even the strongest adhesive may fail to create a secure bond. Following cleaning, selecting a robust adhesive designed explicitly for outdoor applications will contribute to preventing future failures. Weather-resistant adhesives, such as silicone or high-quality epoxy variants, help ensure a durable bond irrespective of temperature swings and moisture exposure.

Moreover, leveraging appropriate application techniques can also influence the longevity of the bond. Using an applicator to apply the adhesive precisely without excess helps ensure an even distribution of the material. In cases where the beads may be exposed to higher risks of impact or movement, consider using additional mechanical fasteners like small brackets or clamps alongside adhesive bonding. Doing so adds a safety net to your installation, providing additional layers of security against potential detachment due to various stressors.

HOW LONG DOES IT TAKE FOR THE ADHESIVE TO CURE COMPLETELY?

Curing times can vary widely depending on the type of adhesive employed, environmental conditions, and the specific instructions provided by the manufacturer. Generally speaking, silicone adhesives may cure within 24 hours under optimal conditions, but full bonding strength could require several days. In high humidity or lower temperatures, the curing process might take longer, so it is crucial to consider these factors when planning your project.

Always refer to the product label or technical sheet for precise information regarding recommended drying and cure times. Techniques such as providing additional warmth or ventilation can help expedite the process, but ensure adherence to safety standards during enhancement methods. Patience during the curing process is vital as insufficient curing could lead to a weak bond, ultimately resulting in the beads loosening or falling off over time.

In summary, taking an informed, step-by-step approach to pasting solar lamp beads can greatly enhance their performance and aesthetic appeal. Proper surface preparation, careful selection of adhesive, precision during application, and allowing for adequate curing time are all integral components in the process. Each of these stages contributes significantly to achieving a long-lasting, reliable bond that withstands the test of time. Knowing the specific requirements for the solar lamp beads and surrounding environments, combined with a commitment to diligence throughout the installation, can ensure optimal functionality and satisfaction with the finished product. Ensuring these best practices are recognized and implemented allows for the effective use of solar lamps, providing sustainable and beautiful lighting solutions for outdoor spaces.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-paste-solar-lamp-beads/