1. Understand the Solenoid Valve Mechanism, 2. Ensure Proper Power Supply, 3. Follow Correct Wiring Procedures, 4. Perform Activation Steps Thoroughly.

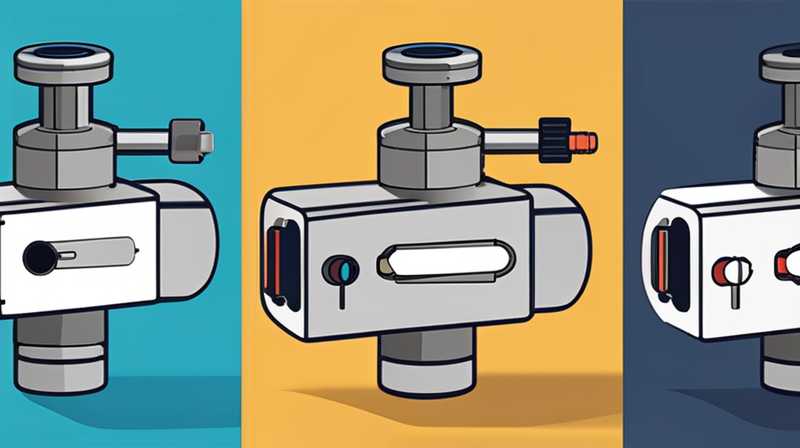

The solenoid valve plays a crucial role in the operation of solar water heaters, controlling fluid flow with efficiency and precision. To initiate the valve, it is paramount to comprehend its operational dynamics along with the necessary components involved in its activation. A proper power supply is essential for the solenoid valve to function adequately, as inadequate voltage can lead to malfunction or non-operation. Careful wiring according to the manufacturer’s guidelines guarantees safety and optimal performance. Performing activation steps meticulously ensures that the valve works seamlessly within the solar system’s framework.

1. UNDERSTAND THE SOLENOID VALVE MECHANISM

The solenoid valve operates based on a coil mechanism, transforming electrical energy into mechanical energy. When an electric current is delivered to the coil, it creates a magnetic field that shifts a plunger or armature, opening or closing the valve to control the flow of liquids or gases. Understanding this fundamental principle is vital, as it helps in diagnosing issues that may arise within the system.

Maintaining a grasp of the mechanics allows for efficient troubleshooting. If the valve fails to open, diagnosing whether the issue lies within the power supply, electrical connections, or the solenoid itself becomes easier. Understanding how the solenoid functions not merely aids in opening the valve but also highlights the importance of routine maintenance to ensure longevity and reliability.

2. ENSURE PROPER POWER SUPPLY

Providing a stable and appropriate power supply is pivotal. The specifications for solenoid valves vary, so it’s crucial to ensure that the voltage supplied matches the manufacturer’s recommendations. Generally, solenoid valves operate on either AC (alternating current) or DC (direct current) systems, each having distinct requirements.

Using a multimeter to check the voltage before connecting the solenoid valve can prevent possible damage from an incorrect power supply. If the voltage is consistent and precise, it ensures optimal operation. Additionally, implementing protective measures, such as fuses or circuit breakers, can safeguard the solenoid from unexpected power surges, ensuring durability and reducing the risk of failure.

3. FOLLOW CORRECT WIRING PROCEDURES

Wiring the solenoid valve requires careful adherence to electrical standards and manufacturer specifications. Utilizing the correct gauge of wire is imperative; undersized wires may overheat and lead to potential malfunctions. Conversely, oversized wires could complicate the installation process.

Before commencing, it’s beneficial to create a wiring diagram. This diagram serves as a visual aid, streamlining the installation process. Ensuring secure connections is equally important; loose wires can cause fluctuations in power delivery, leading to erratic performance of the solenoid valve. Utilize appropriate connectors and, if needed, insulated enclosures for enhanced protection against environmental elements, especially in outdoor applications.

4. PERFORM ACTIVATION STEPS THOROUGHLY

Executing the activation process properly leads to the efficient functioning of the solenoid valve. Initially, verify that all connections are secure and the power supply is as specified. Following this, activate the power source while closely monitoring the solenoid’s response.

Upon activation, observe the valve’s movement. It should respond promptly to the electrical signal. If it does not operate as expected, turn off the power and revisit all previous steps, ensuring that all components are correctly wired and powered. Testing the solenoid valve with a low voltage initially can minimize risks, allowing for adjustments if necessary before applying full voltage.

Regular assessments, including checking for leaks and ensuring that the solenoid valve remains clean of debris, will help maintain efficient operation over time.

FAQS

1. WHAT IS A SOLENOID VALVE?

A solenoid valve is an electromechanical device used to control the flow of liquids or gases in a system. It operates through an electromagnetic solenoid that, when energized, pulls on a plunger to either open or close the valve. These valves are commonly utilized in various applications, including irrigation systems, heating systems, and more, making them essential components in many hydraulic and pneumatic systems. Their reliability and efficiency make them preferable in scenarios where automatic control is required. The versatility in design allows for functioning in various environments, making them vital in both industrial and domestic applications.

2. HOW DO I TROUBLESHOOT A FAULTY SOLENOID VALVE?

To troubleshoot a malfunctioning solenoid valve, begin with a visual inspection. Check for loose wires or physical damage to the valve. Use a multimeter to verify the power supply; ensure it matches the specified voltage requirements. If the voltage is inadequate, you may need to examine your power source. Confirm that the solenoid is receiving current by monitoring the operation when activated. If it still does not function, the solenoid itself may be defective, requiring replacement. Regular maintenance and testing can help preempt issues, but being methodical in identifying each potential fault is vital for successful troubleshooting.

3. CAN I REPAIR A SOLENOID VALVE, OR DOES IT NEED REPLACEMENT?

Repairing a solenoid valve is contingent upon the nature of the damage. In some cases, components such as seals or coils may be replaced. If the solenoid plunger becomes stuck due to debris, disassembly and cleaning may restore function. However, if the core electrical components are damaged, replacement of the entire valve is often more cost-effective. Evaluating the severity and type of failure is essential. For minor issues, replacement parts may suffice, while complex damage usually necessitates acquiring a new valve. Regular inspections can mitigate significant failures, extending the life of your equipment.

Bold: Closing thoughts emphasize the significance of understanding and properly operating solenoid valves in solar systems. With knowledge of the mechanisms, ensuring stable power supplies, adhering to wiring standards, and carefully executing activation procedures, users can optimize the performance and longevity of these critical components. Taking the time to learn and apply these practices will not only facilitate the immediate operation of the solar system but also ensure its reliability over the long term. Embracing preventative maintenance measures will further safeguard against premature failures, allowing users to fully benefit from solar energy solutions. By maintaining diligence regarding these factors, individuals and organizations can achieve efficiency and sustainability in their solar applications, maximizing the advantages that such technology has to offer.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-open-the-solenoid-valve-of-solar/