Opening a solar solenoid valve cover involves several key steps to ensure proper accessibility and functionality. 1. Safety precautions are essential before beginning the process, including disconnecting power sources and ensuring the area is dry. 2. Use the correct tools to avoid damage to the components, specifically a screw driver or appropriate socket. 3. Carefully observe any specific functions of the solenoid valve that pertain to its operation, as improper handling can lead to malfunction. 4. Follow the manufacturer’s guidelines for disassembly, as variations exist across different models. If applicable, consider consulting professionals for assistance to avoid voiding warranties or incurring costly repairs.

1. UNDERSTANDING SOLENOID VALVES

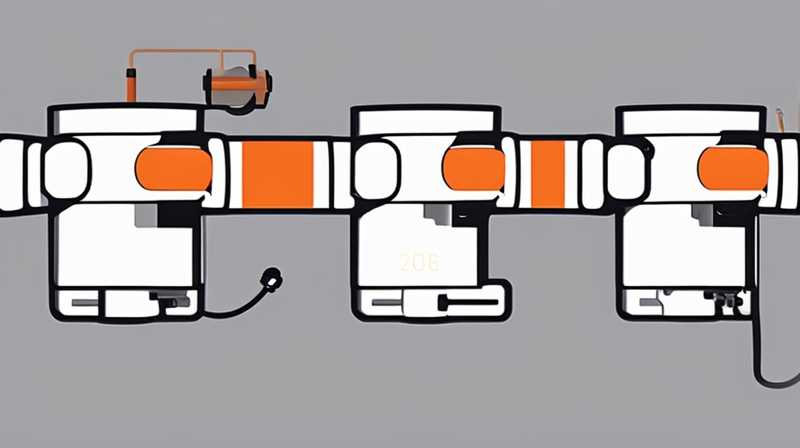

A solar solenoid valve is an electromechanical device that regulates fluid flow in a controlled manner, driven by electrical signals. It mainly finds application in irrigation systems, wherein it helps to automate watering schedules. The unit consists of a valve and an electric solenoid. The solenoid is a coil of wire that generates a magnetic field when an electric current passes through it. This magnetic field activates the valve mechanism, which opens or closes the fluid passage, allowing or blocking water flow based on the electrical command.

The significance of comprehending how these devices operate cannot be understated, especially for those managing land irrigation or other automated water systems. Knowledge of solenoid functionality facilitates troubleshooting, maintenance, and the timely resolution of any issues. In essence, ensuring the proper operation of solenoid valves contributes directly to resource conservation and efficient water management in solar-powered setups.

2. IMPORTANCE OF MAINTENANCE

Routine maintenance of the solar solenoid valve and its cover is critical to prevent unexpected failures. Regular checks can identify leaks, corrosion, and other forms of wear that could compromise its performance. 1. Regular inspections allow users to keep an eye on the valve’s operating condition. 2. Maintenance can also extend the system’s lifespan, thereby reducing overall operational costs. Failure to address minor issues could lead to significant breakdowns, which are often more challenging and expensive to fix.

During maintenance, it is essential to pay attention to various aspects of the solenoid valve, including its electrical connections, mechanical components, and the integrity of the cover. Additionally, the adherence to a maintenance schedule, inclusive of periodic cleaning and inspections, further enhances sustainability. Operators are encouraged to document their findings during each inspection to help in future diagnostics and repairs.

3. TOOLS NEEDED FOR REPAIR

Gathering the necessary tools is a foundational step essential for the disassembly of a solar solenoid valve cover. Depending on the specific model and installation, tools may include a socket wrench, screwdriver set, pliers, and possibly an adjustable crescent wrench for various fasteners. 1. Proper tools ensure a smoother process, minimizing the risk of damage to the components. 2. Using the right equipment reduces the time spent on the task, enabling quicker access to the inner workings of the valve.

It is advisable to avoid makeshift solutions, such as using incorrect-sized tools or inappropriate utensils, as these can lead to stripped screws, damaged threads, or cracked covers. Furthermore, a well-organized workspace equipped with all required tools positions the technician favorably for an efficient workflow. By preparing in advance, one can effectively streamline operations while minimizing interruptions.

4. SAFETY MEASURES AND PRECAUTIONS

Prioritizing safety is imperative when working with electrical and mechanical systems. 1. Disconnecting power sources is crucial to prevent shocks that may occur during valve operations. 2. Wearing protective gear helps mitigate injury should unexpected components become loose or break during the disassembly. In addition to personal safety, ensuring that the work area is clear of obstructions reduces the likelihood of accidents that could impact safety.

It is advisable to conduct a risk assessment before initiating the task, identifying potential hazards associated with the solenoid valve’s environment. Furthermore, users should remain cautious of water pressure within the lines connected to the valve. Following manufacturer guidelines regarding the proper handling of the device greatly reduces the risk of accidental damage or safety hazards. Planning effectively and prioritizing precautions creates a safer working situation for all involved.

5. STEP-BY-STEP GUIDE TO OPENING

Opening the solar solenoid valve cover requires attention to detail and focus on proper techniques. Here’s a brief outline of the process:

- Power Off the System: Before making any adjustments, the first action should be to switch off the power supply to avoid electric shock.

- Assess and Prepare the Area: Ensure that the work environment is free from clutter and that all necessary tools are within reach.

- Remove Fasteners: Utilize the correct drill or screwdriver to carefully remove screws or clips holding the cover in place. Store the fasteners in a designated area to prevent misplacement.

- Gently Lift the Cover: After ensuring all screws are removed, lift the valve cover slowly to avoid damaging any connected wires or components.

- Inspect the Internal Components: Once open, examine the internal parts for wear, damage, or dirt. Cleaning and fixing these parts may be possible before reassembly.

- Replace the Cover: After performing necessary repairs, securely reattach the cover using the previously removed fasteners, ensuring a tight fit without overtightening.

This methodical approach guarantees thoroughness and minimizes the potential for mistakes during the disassembly process.

6. COMMON ISSUES AND TROUBLESHOOTING

Throughout the lifespan of a solar solenoid valve, various issues may arise, requiring troubleshooting skills. 1. Typical problems might include leaking joints, solenoid failure, or irregular pressure levels within the system. 2. Understanding each of these issues allows operators to address them promptly, thereby preventing further complications.

Leaking is often indicative of a worn-out gasket or loose seals. Examining the area around the cover for any sign of dripping or moisture can reveal critical information about the valve’s integrity. On the other hand, solenoid failure may manifest as a complete lack of response when power is applied. Checking the electrical connections, fuses, and the solenoid’s coil can lead to the identification of the cause. Moreover, inconsistent pressure levels may hint at blockage or improper valve settings, necessitating further investigation.

7. WHEN TO SEEK PROFESSIONAL HELP

In some situations, the best course of action is to consult with a professional technician experienced in solar solenoid valve maintenance. 1. If troubleshooting does not resolve the issues present, professional insight may illuminate underlying problems. 2. Moreover, if the solenoid valve is still under warranty, unauthorized modifications can void coverage, necessitating trained assistance.

Seeking expert intervention can not only save time but also provides access to specialized knowledge and tools that might not be available to the average user. Additionally, professionals can often identify complex issues quickly because of their extensive experience with diverse valve systems and their components. Engaging a technician is especially prudent for intricate or critical systems where precision and reliability are paramount.

8. IMPORTANCE OF FOLLOWING MANUFACTURER INSTRUCTIONS

For optimal results, adhering to the manufacturer’s guidelines throughout the maintenance process is paramount. 1. Manufacturer documentation often provides the most accurate information on functioning, assembly, and disassembly procedures. 2. Specific models may include unique configurations or technological enhancements that necessitate specialized knowledge.

Incorporating this guidance significantly reduces the risk of improper handling and enables users to leverage the full potential of their solenoid systems. Furthermore, many warranties stipulate that following the prescribed processes is necessary for maintaining validity; deviation can lead to costly complications or the eventual need to replace the unit altogether. In the competitive field of solar technology, understanding and applying manufacturer recommendations fosters reliability and efficiency in water management systems.

FREQUENTLY ASKED QUESTIONS

HOW DOES A SOLENOID VALVE WORK?

A solenoid valve functions as a switch which opens or closes a pathway for liquids or gases, utilizing an electromagnetic solenoid to electronically control the flow. When an electric current passes through the coil in the solenoid, it generates a magnetic field that moves a plunger within the valve body. This plunger then either blocks or allows the flow of the fluid, depending on whether the valve is in an open or closed state. Different valve types, including normally closed or normally open configurations, dictate how the solenoid behaves when power is applied or lost. For those implementing these valves in a solar irrigation system, understanding their function can streamline maintenance and operational efficiency. Regular inspections and knowledge of troubleshooting techniques can ultimately help in extending the life of such components.

WHAT TO DO IF MY VALVE IS LEAKING?

Should a solar solenoid valve exhibit signs of leaking, immediate action is necessary to mitigate damage and conserve water. The first approach involves turning off the power and water supply to prevent further leakage. After that, careful inspection of the assembly is essential to identify the source of the leak. Common culprits include worn-out gaskets, loose fittings, or damaged seals; these can often be replaced without needing to remove the entire valve assembly. In some cases, tightening connections will suffice, but more severe damage may require gasket replacement or professional intervention. If the problem persists after applying these solutions, consulting an experienced technician should be considered, as they can provide specialized knowledge on more complex issues, ensuring proper resolution.

WHAT ARE THE SIGNS OF A MALFUNCTIONING SOLENOID VALVE?

Identifying malfunctioning solenoid valves is pivotal in maintaining effective water management systems. Common indicators include irregular flow, persistent leaks, or erratic watering patterns. Additionally, a failure to respond to electrical signals or an inability to switch states can point toward internal issues. Other observable signs may entail unusual noises during operation, such as clicking or humming, which may signify that the solenoid is attempting to function but failing. It is essential to conduct a thorough inspection of the entire valve assembly, assessing electrical connections, coil integrity, and mechanical components for wear or damage. Addressing these concerns promptly can aid in preventing more significant operational failures down the line.

ADDITIONAL CONSIDERATIONS

While it may seem simple to open a solar solenoid valve cover, the importance of approaching the task with informed knowledge cannot be overstated. Appropriate preparation, maintaining safety protocols, and utilizing the right tools can save time and minimize potential damages. Commitment to ongoing maintenance and adherence to manufacturer guidance ensures that the system operates efficiently while maximizing its lifespan. In particular, when engaging with complex systems, staying educated on troubleshooting techniques equips users to manage their equipment confidently and mitigate potential disruptions in service.

The journey of mastering the process of opening a solar solenoid valve cover is indeed multifaceted, demanding respect towards both craft and machinery. Understanding the anatomy of the solenoid valve not only aids in effective maintenance but empowers operators with knowledge to handle an array of challenges. Moreover, routine upkeep reinforces system reliability, on the whole. Those who manage such installations are encouraged to cultivate a diligent and proactive approach to maintenance. In doing so, they will not only bolster their knowledge and skillset but also contribute to sustainable resources and improved water management in numerous applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-open-the-solar-solenoid-valve-cover/