Opening a solar battery involves several meticulous steps to ensure safety and proper handling. 1. Ensure safety gear is worn, 2. Disconnect all power sources, 3. Identify the battery type, 4. Carefully remove terminals, and 5. Access the battery compartments. Among these, understanding the battery type is crucial due to the varying methods required for different battery technologies. For instance, lithium-ion batteries typically demand different handling when compared to lead-acid types. It is imperative to follow specific protocols based on the manufacturer’s guidelines to avoid hazardous situations.

1. UNDERSTANDING SOLAR BATTERY TYPES

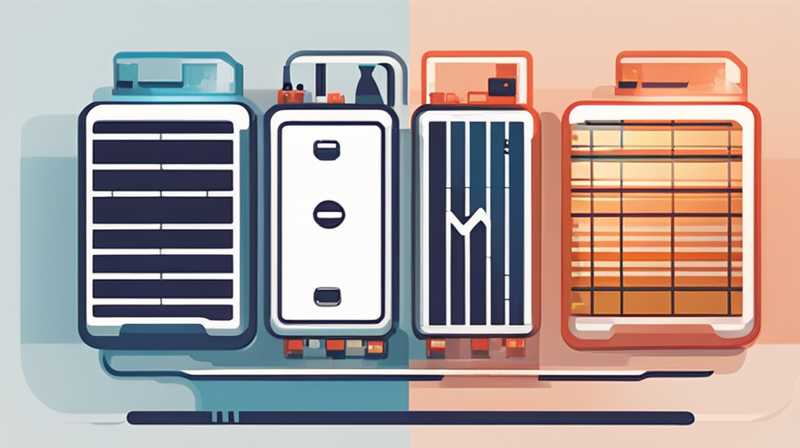

When embarking on the journey to open a solar battery, the type of battery greatly influences the approach taken. Typically, the major types include lead-acid, lithium-ion, and nickel-cadmium, each exhibiting distinct characteristics and functionalities. Recognizing these differences not only shapes the method of opening these batteries but also dictates the safety precautions necessary during the process.

Lead-acid batteries are widely acknowledged for their durability, cost-effectiveness, and simplicity. They are composed of lead plates submerged in a sulfuric acid electrolyte, generating a chemical reaction that stores energy. Opening these batteries frequently occurs for maintenance purposes, especially to check the fluid levels or replace the electrolyte. Conversely, lithium-ion batteries are predominately favored in contemporary solar solutions due to their efficiency, lightweight nature, and longer lifespan. Their complex internal structures necessitate specific care during the opening process to prevent damage to sensitive internal components.

Prior to commencing any actions, a thorough comprehension of the battery type provides a foundation for safe handling and successful extraction of its contents. Each battery carries unique risks and procedures, thereby underscoring the importance of this initial step.

2. ESSENTIAL TOOLS AND SAFETY EQUIPMENT

Selecting the appropriately tailored tools is paramount for safely accessing solar batteries, as improper usage can lead to detrimental consequences. For effective battery opening, certain tools should be obligatory, including insulated wrenches, screwdrivers, and safety goggles. Insulated wrenches are specifically designed to prevent accidental electrical shocks while handling battery terminals.

Protective equipment, such as gloves and goggles, offers an additional layer of security. The electrolyte solutions found in specific battery types—most notably lead-acid batteries—can be caustic, posing a significant risk to skin and eyes. The utilization of safety equipment not only enhances individual protection during the procedure but also assures that mundane tasks do not result in severe injuries.

Ensuring tools are well-maintained and clean guarantees optimal performance. Rusty or worn tools can compromise efficacy, making them a liability during the precarious task of battery opening. Attention to detail in selecting and maintaining equipment dovetails with adequate safety procedures to navigate this intricate task.

3. DISCONNECTION OF POWER SOURCES

Before initiation of the battery opening process, disconnecting all power sources is a paramount step that cannot be overlooked. This procedure prevents inadvertent electrical shocks or short circuits while exposing battery terminals and compartments. Each solar power system—regardless of the configuration—typically involves connections to inverters or charge controllers that facilitate energy conversion and storage. Therefore, it is imperative to identify the pertinent components and safely power them down.

After powering down the system, review the connections for any residual power. Residual voltage can impact safety and complicate the battery opening tasks. If the battery is equipped with built-in shutoff options, activating these can streamline disconnection efforts, minimizing manual handling of connections.

Following the disconnection of all power sources, individuals should utilize voltage testers to confirm the absence of hazardous voltage levels. Regular testing vigilance ensures that safety measures remain robust throughout the entire battery handling process.

4. TERMINAL REMOVAL TECHNIQUES

Once the power has been entirely disconnected, the meticulous removal of battery terminals remains a critical operation. This task necessitates a careful approach, ensuring that polarity and the order of removal are followed precisely. Positive and negative terminals should be removed in the correct sequence to mitigate the risk of shorting the battery.

Initiate terminal access by loosening the nuts or screws holding the terminals in place. Utilizing the insulated wrench, gradually loosen the connector, taking care not to apply undue force that might damage the terminal or create sparks. After ensuring that the terminal is free, carefully lift it away, conducting visual inspections for corrosion or damage. Any signs of wear necessitate immediate attention before further engagement with the battery.

The second terminal should follow a similar process but must always adhere to the determined removal order. Making a routine of this procedure can significantly enhance safety while facilitating a smoother removal experience.

5. ACCESSING BATTERY COMPARTMENTS

With the terminals successfully removed, the next phase involves a careful examination of the battery casings to identify access points. Different battery types present distinct compartment formats that require specific handling techniques. For example, many lead-acid batteries feature removable caps that allow for internal inspections, while lithium-ion batteries often employ a more complex casing that demands additional caution during access.

Once access points are located, examine the battery label or manufacturer’s guidelines for instructions on how to open the compartments. Achieving this may require removal of screws or clips. Proceed with a gentle hand to avoid damaging any internal wiring or components during this endeavor.

After all locking mechanisms are disengaged, the removal of the casing should be conducted smoothly to reveal the internal components of the battery. Associated parts should be handled with the utmost care to avoid injury or device compromise.

6. HANDLING INTERNAL COMPONENTS

Upon successfully accessing the internal sections of the battery, the focus then shifts towards understanding the makeup and functionality of its components. Battery management systems, cells, and internal circuitry need meticulous attention. This engagement not only aids in evaluating the condition of the battery but also reinforces the importance of responsible handling.

Battery management systems (BMS) often control charging and discharging processes within lithium-ion setups. This compact circuitry regulates myriad factors, including temperature and voltage, to optimize performance. Gaining knowledge about the BMS allows for improved troubleshooting and enhanced operational understanding. It’s imperative to handle these components with care, avoiding static electricity, which can severely impact sensitive electronics.

Lead-acid batteries typically have simple designs comprising lead plates and electrolyte solutions, yet improper management can spur internal short circuits or leakage. Utilizing suitable methods to inspect and replace essential components ensures longevity and restores functionality without risking systemic depletion.

7. REASSEMBLING AND MAINTENANCE TIPS

Once the required maintenance or modifications are completed, the focus shifts back to the reassembly of the battery. Proper reassembly is crucial to ensure continued optimal performance post-handling. Be attentive to the correct installation order for terminals, starting with the positive terminal followed by the negative, ensuring secure connections to prevent future complications.

Inspect all casing sections prior to final resealing. Confirm that screws or clips are securely fastened, as well as checking for any apparent structural integrity issues that might disrupt the battery’s functionality. Proper reassembly ensures that energy flow remains consistent.

Maintenance practices should be embraced to enhance battery longevity and operational safety. Regular inspections for corrosion, electrolyte levels, and visual damage to terminals are imperative in mitigating long-term issues. Ensuring clean connections without debris or oxidation will enhance overall efficiency when operating your solar battery system.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I MAINTAIN MY SOLAR BATTERY?

Maintaining solar batteries is crucial for achieving optimal performance and longevity. It is generally advisable to perform maintenance checks at least bi-annually. The frequency may, however, vary depending on usage patterns, environmental conditions, and specific battery types. Regular inspections should encompass checks for corrosion on terminals, ensuring appropriate electrolyte levels in lead-acid batteries, and evaluating the overall physical condition of the battery.

Additionally, leveraging monitoring systems can aid in identifying unusual patterns in battery performance, signaling the necessity for further examination. For lithium-ion batteries, while they typically require less frequent maintenance due to their advanced technology, periodic checks are advisable to preserve optimal functioning.

By adhering to a diligent maintenance schedule, users can enhance efficiency and prolong the lifespan of their solar battery systems, ensuring that investments remain sound over the years.

WHAT TO DO IF MY BATTERY LEAKS?

In the event of a leak, immediate action is paramount to prevent hazardous situations. First and foremost, prioritize personal safety by donning appropriate protective gear, including gloves and goggles. Locate the source of the leak and establish a safe distance if necessary, particularly with lead-acid batteries, as they contain corrosive acid which can be dangerous to skin and eyes.

If a leak is detected, immediately isolate the battery by disconnecting all power sources and ventilating the area. Next, consult the manufacturer’s guidelines for specific cleanup procedures. In many cases, neutralizing agents may be recommended to clean up any acid spillage. It is advisable to contact professionals or hazardous material experts for assistance in serious situations, preventing further risks.

Lastly, assess the viability of the battery—if the leak is significant or damage is extensive, replacement may be the safest option to ensure continued reliable operation of your solar energy system.

CAN I OPEN A SOLAR BATTERY MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Opening a solar battery may be undertaken by individuals with adequate knowledge and comfort regarding the procedures involved. However, for those unfamiliar with battery technology or lacking experience, it is strongly suggested to engage a professional. Many complexities associated with battery types and the potential for dangerous reactions underscore the wisdom of seeking expertise.

Professionals are equipped not only with knowledge but also with tools and safety equipment paramount for performing battery-related tasks efficiently. Their experiences prepare them for unexpected scenarios that may arise, ensuring completion of the work without damage to equipment or risk of personal injury.

Should individuals choose to proceed independently, they must thoroughly educate themselves on applicable safety procedures and guidelines. Ensuring that they possess the recommended tools and understanding their battery type is essential for navigating potential issues.

Navigating the complexities involved in opening a solar battery demand attention to detail, adherence to safety protocols, and understanding the performance of different battery technologies. The journey unfolds through carefully analyzing the battery type, essential tools, and disconnection processes, leading to secure terminal removal, careful access of compartments, and responsible handling of internal components. As reassembly and sustained maintenance approaches unfold, remaining aware of effective practices and potential complications informs sound decision-making. The process ultimately emphasizes safety and professionalism, making careful consideration of when to engage with experts imperative for overall efficiency and security. By remaining vigilant and proactive, individuals can ensure their solar energy systems operate effectively, maximizing the lifespan and utility of critical battery components.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-open-a-solar-battery/