To measure solar tube rubber pads accurately, it is essential to follow a few systematic steps. 1. Identify the type of pad, 2. Measure the pad’s diameter, 3. Determine the thickness, 4. Check for any specific design features. The type of rubber pad can affect its functionality and compatibility with solar tubes; therefore, identifying it is crucial. The diameter measurement ensures that the pad fits correctly within the assembly or system without any leakage. Thickness is important also as it affects the cushioning and insulation properties. Additionally, design features such as grooves or ridges must be taken into account, as they may influence the overall performance of the solar tube system. Ensuring precise measurements will contribute to the efficiency and longevity of the solar tube installation.

1. UNDERSTANDING SOLAR TUBE RUBBER PADS

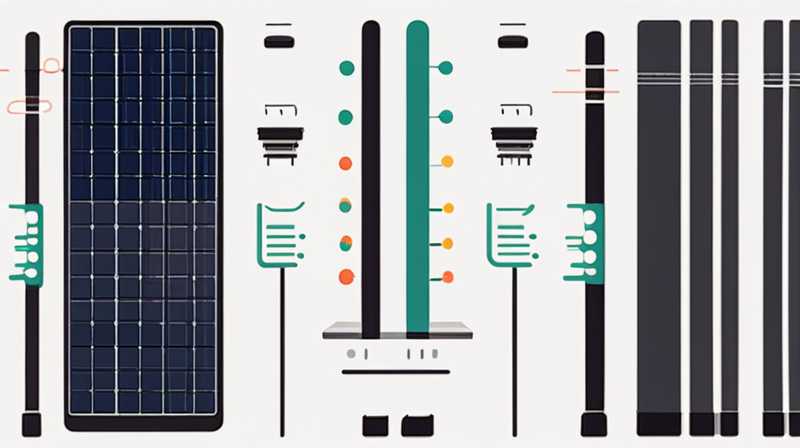

Solar tubes, or solar thermal collectors, rely on various components to efficiently harness energy from the sun. One such component is the rubber pad, which plays a critical role in mitigating vibrations and maintaining structural integrity. Understanding the significance of these pads is vital, as they help prevent potential damage, ensuring longevity and efficiency in performance. The rubber pads provide a functional barrier, isolate parts, and allow for thermal expansion.

The solar tube rubber pads come in varying types, materials, and designs. Different types serve distinct applications, and understanding their purpose is fundamental to their effective utilization. The material properties of rubber can significantly enhance or diminish the performance of solar thermal systems, as factors such as temperature resistance, flexibility, and durability impact the overall efficiency of energy absorption and retention.

2. IMPORTANCE OF ACCURATE MEASUREMENTS

Precision is paramount when it comes to measuring solar tube rubber pads. Accurate measurements help ensure compatibility, promote effective sealing, and ultimately enhance overall performance. The significance lies not only in the immediate functionality but also in the long-term viability of the solar thermal system. Incorrect sizes may lead to ineffective connections, resulting in energy loss and potential damage.

Furthermore, exact dimensions eliminate uncertainty during installation. For solar tube systems to function optimally, all components, including rubber pads, must fit together seamlessly. The implications of improper sizing extend beyond discomfort during installation; they can also lead to costly repairs and maintenance over time. Ensuring high accuracy mitigates risks associated with thermal expansion and contraction, which is critical given the variable temperatures that solar thermal systems often face.

3. TOOLS AND TECHNIQUES FOR MEASUREMENT

Utilizing the right tools and techniques is essential for precise measurements of solar tube rubber pads. Common instruments include calipers, measuring tapes, and specialized gauges that offer enhanced accuracy. Each tool has its advantages; for instance, calipers provide a highly precise measurement of both external and internal diameters, while tapes offer simplicity in length measurement.

In addition to appropriate tools, employing the correct measuring techniques also contributes to overall accuracy. For diameters, it’s crucial to take multiple measurements at different points to account for any irregularities. Thickness can be assessed by comparing measurements at various locations on the pad, which ensures uniformity. Consistent practice of these methods will lead to better data collection and an enhanced understanding of pad specifications.

4. STEP-BY-STEP MEASUREMENT PROCESS

The process of measuring solar tube rubber pads should involve clear, methodical steps to ensure accuracy. The initial step involves selecting the pad and cleaning its surface to avoid any debris that might impact measurements. Once the site is prepared, the diameter is measured. This can be performed using calipers or a measuring tape, ensuring both ends of the pad are accounted for.

After determining the diameter, attention must turn to the thickness. This typically involves selecting a few strategic points on the pad, measuring each to confirm consistency. Taking an average of these measurements can provide a reliable estimate of the pad’s thickness. Creativity is key here; variations in technique may arise due to the pads’ physical characteristics. Documentation of each measurement is paramount, as unforeseen discrepancies can occur during installation and need addressing to maintain effectiveness.

5. EXPLOITING MEASUREMENT VARIABILITY

Understanding potential variability in measurements can aid significantly in achieving more precise results. Factors such as temperature, pressure, and rubber compound variations can affect measurements. By recognizing these discrepancies early, one is better prepared to respond proactively to any potential problems arising from design flaws or material inconsistencies.

It is essential to evaluate measurements through a critical lens, taking into account the conditions that were present at the time of measurement. Adjusting for any known variances, especially those linked to environmental conditions or inherent material characteristics, can lead to improved installation and operational outcomes. Notably, professional opinions from experienced installers or engineers should be sought, particularly for unique or complex applications involving specialized pads.

6. COMMON MISTAKES IN MEASUREMENT

Awareness of prevailing errors can lead to more successful measuring practices. Many individuals overlook the importance of consistent measurement techniques, which can lead to significant discrepancies. Measuring without accounting for rounding can also cause inaccurate data, resulting in improper pad dimensions.

Additionally, failing to regularly calibrate tools can introduce inconsistent readings. Professionals must take care to ensure that their measuring instruments are always functioning accurately and are checked periodically. Documentation of the measurement process can also be invaluable in avoiding common pitfalls, enhancing accountability, and ensuring clarity throughout the project lifecycle.

7. AFTER MEASUREMENT: NEXT STEPS

Once all necessary measurements have been conducted and documented, the next steps can unfold. Choosing the right rubber pad involves consideration of the specific requirements of the solar tube system. Key factors like temperature resistance, compression set, and dynamic performance should be evaluated alongside measurement results.

After selecting a suitable pad based on measurements and requirements, it’s vital to proceed with proper installation techniques. Following guidelines provided by manufacturers or experts can ease the installation process, thereby enhancing the performance of the solar thermal system. Overall, keeping a holistic view of both measurements and overall requirements sets the stage for further efficiency in energy retention and collection.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE COMMONLY USED FOR SOLAR TUBE RUBBER PADS?

Various materials may be utilized for solar tube rubber pads, each offering unique characteristics suited to specific applications. One of the most common materials is EPDM rubber, renowned for its durability and resistance to weather conditions. EPDM exhibits excellent resistance to ultraviolet light, ozone, and high temperatures, making it an ideal choice for applications exposed to solar radiation.

Another frequently used material is neoprene, which provides additional benefits related to flexibility and resistance to oils and solvents. Neoprene’s resistance to environmental factors makes it a go-to option in diverse settings, ensuring prolonged functionality. PVC and silicone pads are also utilized occasionally; they offer distinctive benefits tailored to particular conditions. Overall, the choice of material is crucial in determining the effectiveness and service life of rubber pads in solar tube installations.

HOW DOES THE THICKNESS OF A RUBBER PAD AFFECT PERFORMANCE?

The thickness of a rubber pad directly impacts performance in several ways. First and foremost, thicker pads typically provide superior shock absorption, which can reduce vibrations transmitted through the system. This characteristic is particularly relevant in scenarios where the solar tubes must endure movement or thermal expansion, as the cushioning effect can aid in preventing potential damage.

Additionally, thickness can influence thermal insulation properties. A thicker pad usually facilitates better insulation and heat retention, which may enhance the overall efficiency of the solar energy system. However, it’s essential to find the right balance; overly thick pads may compromise mechanical stability or lead to misalignment within the system. Therefore, careful consideration of thickness must be given, considering the specifics of each solar tube application.

CAN MEASUREMENTS CHANGE OVER TIME?

Yes, measurements can indeed change over time due to various factors. Rubber pads can undergo deformation due to exposure to temperature fluctuations, compression, and dynamic loads. Over time, prolonged exposure to harsh environmental conditions can lead to wear and deterioration, subsequently altering their original dimensions. This phenomenon is particularly noteworthy in applications subjected to regular movement or strain, as the silicone compound’s elasticity may change.

Regular monitoring and measurement checks are advisable to ensure that the rubber pads continue to function as intended. Performing routine inspections can help catch any issues early, allowing for timely replacement or adjustments. A proactive approach to maintenance will contribute significantly to the longevity and efficiency of the entire solar thermal installation.

When it comes to accurately measuring solar tube rubber pads, it creates a foundation for the efficient function of solar thermal systems. By meticulously carrying out the measurement process and employing the right techniques, one can ensure that these critical components are tailored to fit seamlessly within their respective applications. All elements discussed, ranging from understanding the material properties to avoiding common pitfalls in measurement, contribute to achieving a culmination of excellence in solar technologies. Therefore, practitioners must remain diligent and proactive in continuously assessing and refining the measurement process to adapt to evolving conditions and achieve sustained performance.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-measure-solar-tube-rubber-pads/