1. Marking solar tubes involves a systematic approach, focusing on 1. identification of the solar tubes, 2. choosing appropriate marking materials, 3. implementing a clear marking system, and 4. maintaining consistent updates. Properly marking solar tubes is crucial for ensuring efficient operation, easy maintenance, and safety.

Identification of Solar Tubes

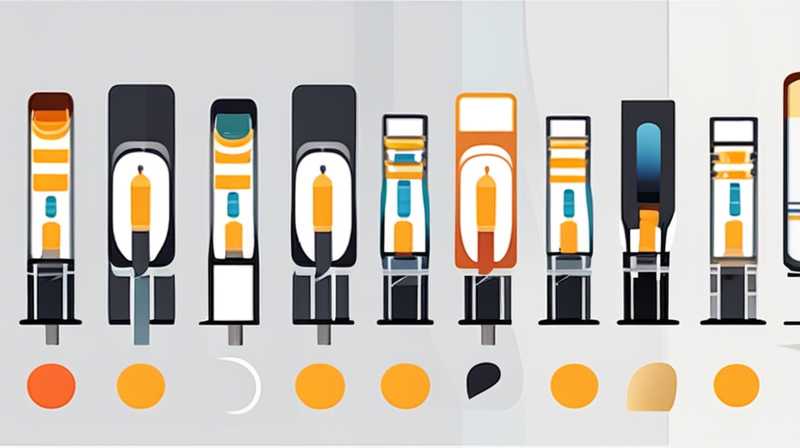

When embarking on the task of marking solar tubes, it is essential to start with an accurate identification of the components involved. Solar tubes, often referred to as evacuated tube collectors, are utilized in solar thermal systems. Typically, these tubes consist of an outer glass layer and an inner selective coating that absorbs solar energy. Knowing the specifications of each tube, such as type, size, and intended function, establishes a foundational understanding for the marking procedure. It’s vital to distinguish different types of tubes or systems, as identification facilitates effective management.

A thorough understanding of the physical layout of solar tubes within the system is also paramount. By mapping out the installation, operators can create a reference point that aids in the localization of each component at a glance. For instance, marking the inlet and outlet connections, as well as control valves, is instrumental for quick diagnostics during maintenance checks. Additionally, labeling the tubes based on their particular roles or operational parameters—such as temperature limits and pressure ratings—greatly enhances the functionality of the entire solar thermal setup.

Material Selection for Marking

Choosing appropriate marking materials is equally significant. The longevity and visibility of the marking solution will directly influence the effectiveness of the identification system. Options may include weather-resistant paints, durable stickers, or engraved tags. The durability of these materials is crucial, as solar tubes are often exposed to varying weather conditions, including UV radiation and precipitation. Therefore, utilizing non-fading and resistant options ensures that markings remain legible over time.

Furthermore, selecting the correct size and font for the markings is vital. It is best to opt for larger fonts that can easily be read from a distance. Contrast in colors between the marking and the base material will enhance visibility. For example, using bright colors against dark surfaces provides a good solution for identification. Additionally, opting for more permanent solutions like engraving can ensure that the markings do not peel off or fade, thereby maintaining their utility over the lifespan of the tubes.

Implementing a Clear Marking System

Establishing a clear and concise marking system plays a crucial role in enhancing efficiency. This system should be standardized across all solar tubes to ensure uniformity in identification. Clearly defined categories for marking, such as elevation levels, temperature ratings, or flow directions, can significantly improve operational efficiency. Creating a numerical or color-coded system allows for quick referencing, reducing the time spent identifying specific tubes during inspections or repairs.

Moreover, incorporating digital technologies can further streamline the marking process. By using QR codes linked to detailed databases, workers can access important information about each tube simply by scanning the code. This can include specific maintenance schedules, operational manuals, and historical data on performance. Such innovations in the marking system enhance knowledge transfer among team members and provide a reliable resource for troubleshooting.

Maintaining Consistency and Updates

Maintaining consistent updates of the marking system is necessary for ensuring that all records remain current. As systems evolve, new tubes may be added or replaced, meaning the existing marking system should be reassessed to accommodate these changes. Regular audits and reviews of the markings can help identify any outdated or removed information, calling for corrections to keep the data relevant.

Additionally, training staff on the importance of marking systems enhances adherence to consistency. Regular briefings and workshops regarding the significance of the marking strategy foster a culture of diligence and accountability among the teams involved. This proactive approach to marking solar tubes will not only enhance operational efficiency but also promote a longer lifespan for the system as a whole.

FAQ SECTION

WHAT MATERIALS ARE BEST FOR MARKING SOLAR TUBES?

When selecting materials for marking solar tubes, durability is key. Preferred options include weather-resistant paints, durable stickers, or engraved tags. Weather-resistant paints ensure long-lasting visibility, while durable stickers can provide a flexible option that is easy to apply. Engraved tags, though typically more expensive, offer permanence and clarity while resisting environmental elements. It is critical to choose contrasting colors to enhance visibility, as markings must be easily readable even from a distance. In addition to selecting the right materials, it’s important to consider the placement of markings. Ideal locations include the ends of tubes or near connections, ensuring minimal obstruction and maximum accessibility during maintenance. Regular inspections of these markings should be conducted to determine if they remain clear and functional over time.

HOW DOES A PROPER MARKING SYSTEM IMPACT MAINTENANCE OF SOLAR TUBES?

A properly implemented marking system substantially influences the maintenance of solar tubes by enhancing identification and accessibility. With clear labels indicating the function, flow direction, or specifications of each tube, maintenance personnel can quickly locate the component that requires attention. This streamlined approach reduces the downtime of solar thermal systems and minimizes the risk of errors during inspections. By adopting a standardized marking system, teams can ensure that they all refer to the same identifiers, eliminating confusion. Furthermore, a well-established marking system can help track performance metrics over time. For example, knowing which tubes operate under varying conditions—and their corresponding markings—enables staff to assess performance trends, thus facilitating proactive measures for maintenance. Overall, effective markings lead to more efficient troubleshooting, which safeguards the overall integrity and efficiency of the solar thermal system.

HOW OFTEN SHOULD MARKINGS ON SOLAR TUBES BE UPDATED OR REPLACED?

Updating or replacing markings on solar tubes should ideally occur during routine maintenance checks, typically scheduled annually or biannually. However, any significant changes in the system’s configuration—such as the addition of new tubes or components—should prompt immediate reassessment and updating of the markings. Over time, environmental factors may deteriorate markings, particularly if visible signs of wear or fading occur. Therefore, a regular inspection process is critical to maintaining clarity and functionality, directly correlating to the system’s overall efficiency. If a marking is no longer legible, it should be replaced as soon as possible to avoid operational disruptions. Additionally, implementing a system to track when and how often markings were inspected or replaced can create a reliable history, allowing for better planning of future maintenance activities. Regularly updating these identifiers will ultimately contribute to more effective identification and operational integrity of the solar systems.

IN ESSENCE, marking solar tubes is a multifaceted task that cannot be overlooked. An investment in proper identification techniques, suitable materials, a structured marking system, and consistent updates not only enhances the operational efficiency of solar thermal systems but also enriches safety procedures. Each point underlines the importance of understanding the various factors involved and emphasizes how this knowledge contributes to successful management and maintenance strategies. By understanding the unique requirements of the environment, the identification processes, and the importance of visibility and consistency, operators can create a robust marking approach that serves the entire lifecycle of the solar thermal installation. The collaboration between installation teams and ongoing maintenance personnel is essential to ensure that these marking standards are adhered to, consequently maximizing performance and extending the longevity of the system. Moreover, embracing technology, alongside traditional methods, can streamline the marking experience. In a world increasingly focused on sustainability, efficient solar thermal solutions supported by well-marked systems will lead to better resource management and environmental benefits.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-mark-solar-tubes/