To manually close a solar solenoid valve, follow these essential steps: 1. Identify the valve location, 2. Shut off the power supply, 3. Locate the manual override, 4. Turn the manual override knob or lever, 5. Ensure the valve is securely closed.

In detail, the first step involves determining the exact placement of the solar solenoid valve within your system. It is crucial to know where the valve is located to access it easily. Once you locate the valve, it is necessary to turn off the power supply to prevent any accidental operation. This ensures both your safety and the longevity of the valve.

Next, locate the manual override feature on the solenoid valve. Many solenoid valves come equipped with this feature for situations where electrical control cannot be applied. After finding the override, turn the knob or lever accordingly to close the valve. Finally, verify that the valve is completely closed to prevent any potential leaks. This entire process can be critical for maintaining system integrity and operational efficiency.

1. UNDERSTANDING SOLENOID VALVES

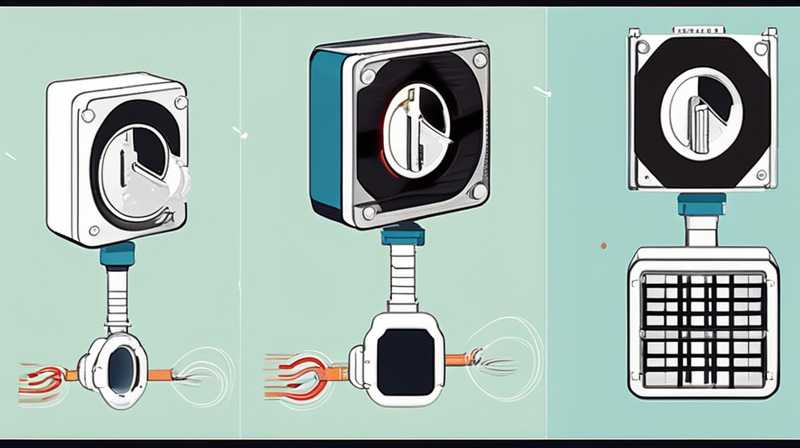

To comprehend how to manually close a solar solenoid valve, one must first understand the concept of solenoid valves. A solenoid valve is an electromechanical device designed to control the flow of liquid or gas. Typically powered by an electrical signal, these valves consist of a coil and a movable plunger. The coil generates a magnetic field when electricity flows through it, prompting the plunger to open or close the valve.

The primary function of these valves is to automate control in various applications, particularly in solar-powered systems where fluid regulation is crucial. In solar thermal systems, for instance, solenoid valves manage the flow of heat transfer fluids. This regulation ensures that heat is appropriately transferred from solar collectors to storage tanks, significantly enhancing system efficiency. Thus, understanding the operational mechanics of solenoid valves is essential for effectively managing and troubleshooting associated systems.

2. IMPORTANCE OF MANUAL CLOSURE

While most solenoid valves function automatically, there are situations when manual closure becomes essential. Such instances may arise during maintenance, repairs, or emergencies where immediate action is required to prevent system failure or damage. In solar energy systems, for example, a malfunctioning valve can lead to loss of heated fluid or even system overheating.

Manual closure procedures ensure that operators have direct control over the flow within the system. This control is particularly significant when calibrating the system for optimal performance or isolating a portion of piping to conduct repairs. Such manual intervention can minimize fluid loss and associated costs. Understanding why and when to close these valves manually is vital for effective system management.

3. SAFETY CONSIDERATIONS

When undertaking any maintenance work involving solenoid valves, safety should always be the foremost concern. Before proceeding with the manual closure, ensure that you are equipped with appropriate safety gear, including gloves and goggles. Additionally, it is advisable to ensure that the surrounding area is free from hazards that could jeopardize safety during the process.

Furthermore, double-check that the power supply is completely turned off. Failure to do so could result in sudden valve activation, leading to unintended consequences. A thorough understanding of the system’s layout is equally important. Identify piping routes and potential fluid contents to avoid exposure or spillages. Adhering to safety protocols can significantly reduce the risk of accidents during manual interventions with solenoid valves.

4. TOOLS REQUIRED FOR MANUAL CLOSURE

Manual closure of a solar solenoid valve generally requires specific tools to facilitate the process efficiently. One commonly needed tool is a wrench, which helps in accessing the valve mechanism and adjusting the manual override. Depending on the design of your solenoid valve, you may also need screwdrivers to remove protective covers or panels.

In addition, a flashlight can be beneficial for inspecting dark spaces or areas where visibility is limited. Having these tools ready prevents unnecessary delays and aids in a smooth manual closure procedure. Beyond these standard tools, familiarize yourself with the valve manufacturer’s specifications. These documents often provide insights into specific tools or techniques required for your particular solenoid valve model.

5. STEPS FOR MANUAL CLOSURE

To ensure a comprehensive understanding of manually closing a solar solenoid valve, the following steps provide clear guidance. First, verify that the power supply is indeed off and that the valve is safely accessible. Look for the manual override feature, typically marked for ease of identification.

Once located, utilize your chosen tools to manipulate the override, turning it in the direction indicated by the manufacturer. It often involves rotating a knob or throwing a lever. After adjusting the override, check to confirm that the valve has closed completely; a straightforward inspection can suffice. This hands-on process reinforces the operational control necessary for optimal management of solar systems.

6. TROUBLESHOOTING COMMON ISSUES

In practice, several challenges may arise when attempting to close a solar solenoid valve manually. One common issue is resistance in turning the manual override; this could signal that the valve is stuck or obstructed. In such cases, do not force the mechanism, as this could lead to further damage. Instead, carefully inspect the valve for debris or other blockages and clear them as necessary.

Another frequent challenge is improper sealing after manual closure. If fluid continues to seep from the valve post-closure, it might indicate wear or damage within the valve assembly. In this situation, it could be prudent to consult technical resources or seek assistance from a professional to address potential valve replacement or repairs. Tackling these problems with a methodical approach contributes to long-term operational success.

7. REGULAR MAINTENANCE TIPS

Implementing a routine maintenance schedule is crucial to prolong the life of the solar solenoid valve and ensure its reliable performance. Regular checks can help identify wear or damage before issues escalate. During maintenance sessions, assess the valve’s external condition, checking for leaks or corrosion.

Aside from inspections, much like any mechanical component, solenoid valves may require periodic cleaning to prevent buildup that impedes functionality. Use compatible cleaning agents as specified by the manufacturer, and remember to recheck the manual override feature. Ensuring these elements are regularly attended to significantly reduces the frequency of emergency manual closures and enhances overall system resilience.

FAQs

WHAT TO DO IF THE MANUAL OVERRIDE IS STUCK?

If the manual override on a solar solenoid valve is stuck, do not attempt to force it, as this can cause irreparable damage. It’s advisable first to inspect the valve visually for debris or corrosion that may hinder movement. Sometimes, a gentle application of penetrating oil can help loosen the mechanism. If the problem persists, consult the manufacturer’s documentation or technical support to avoid further complications. Planning regular maintenance can help prevent such issues, as routine checks can catch problems before they escalate.

HOW OFTEN SHOULD I CHECK MY SOLENOID VALVE?

The frequency of checks on a solar solenoid valve can vary based on usage conditions and the specific application. In general, it is prudent to inspect the valve every three to six months. Increased usage or exposure to harsh environmental conditions can necessitate more frequent evaluations. During these inspections, look for signs of wear, leakage, or corrosion, and assess the functionality of both the automatic and manual mechanisms. Incorporating regular maintenance into your routine not only ensures efficient operation but also increases the lifespan of the valve.

CAN I REPAIR A DAMAGED SOLENOID VALVE MYSELF?

While small repairs and adjustments can often be tackled individually, extensive damage to a solar solenoid valve may require professional assistance. If you are confident in your skills, consult the manufacturer’s guidelines for repair procedures relevant to your specific valve model. Replacement parts may be available, allowing for straightforward fixes if the damage is limited to non-critical components. However, complex malfunctions or severe wear typically warrant the expertise of a qualified technician to maintain system integrity and safety.

Regular maintenance and understanding the importance of manual closure in a solar solenoid valve system are paramount for safe and effective operation. Manual closure plays a vital role, ensuring operators have direct control over the flow and maintaining system integrity during troubleshooting and maintenance. The steps for manual closure, tools required, troubleshooting tips, and maintenance strategies collectively enable operators to proficiently handle solenoid valves. Avoiding potential damage or hazards while maintaining functionality is an overarching goal. Knowledge and preparedness allow for enhanced operational efficiency, ensuring solar systems continue to deliver optimal performance. Engaging with the manufacturer’s documentation and seeking guidance when faced with challenges not only empowers users but also enriches their understanding throughout the process. Proper application of these insights fosters a seamless experience while handling solar solenoid valves, promoting a reliable and sustainable approach to fluid management over time.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-manually-close-the-solar-solenoid-valve/