How to make the wick of solar light tube

1. The wick of a solar light tube can be made using various materials, ensuring optimal light diffusion, and efficiency. 2. Selecting appropriate wick materials enhances light output and durability. 3. Proper construction techniques contribute to longevity and performance. 4. Regular maintenance and adjustments can significantly enhance luminosity and functional efficiency. To craft an effective wick for a solar light tube, one should prioritize material selection, construction techniques, and maintenance practices.

1. UNDERSTANDING SOLAR LIGHT TUBES

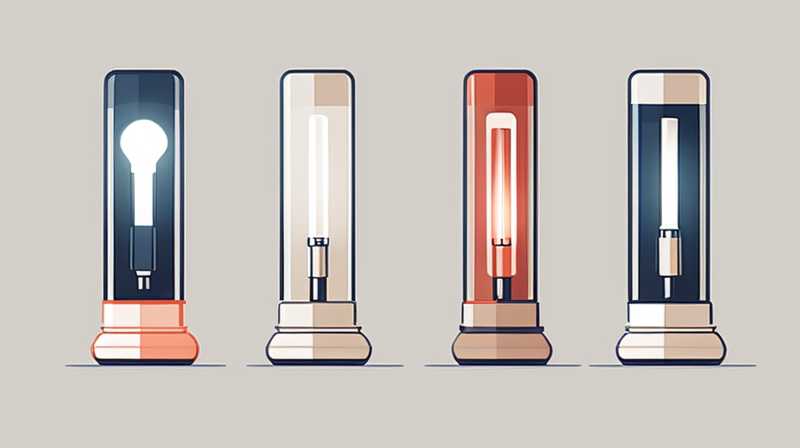

Solar light tubes are innovative devices designed to capture sunlight and deliver it indoors, providing a natural and vibrant lighting source. The fundamental principle involving these tubes relies on light diffusion through a specially constructed wick, which absorbs and distributes light evenly. Light transfer efficiency is contingent upon the materials and construction of the wick. A well-crafted wick captivates sunlight effectively and maintains its intensity over extended periods.

When discussing the efficacy of solar light tubes, it is crucial to understand that the wick acts as an intermediary between sunlight and the living space. Selecting high-quality materials significantly influences how light is harnessed and subsequently dispersed. Factors including wick thickness and texture also play a critical role in their performance, leading to variations in brightness and stability.

2. MATERIAL SELECTION FOR THE WICK

The selection of materials is paramount when creating a wick for solar light tubes. Various fabrics, such as cotton, linen, or synthetic alternatives, can be employed, each providing distinct advantages. Cotton wicks, for instance, are known for their absorbent properties and their ability to diffuse light effectively. They generally increase the overall luminosity of the device while contributing to its longevity, making them a favorable choice for many.

On the other hand, synthetic materials often display durability that surpasses natural fibers, providing longevity against environmental factors such as humidity and temperature variations. Additionally, synthetic options can be designed to enhance specific properties such as thermal resistance, thereby enhancing their functional capabilities. The choice ultimately depends on the intended style and efficiency desired from the solar light tube.

3. CONSTRUCTION TECHNIQUES

Proper construction methods are vital to ensuring a high-performing wick for solar light tubes. Establishing an efficient wick involves several steps that require precision and attention to detail. Cutting the selected material to the appropriate size is essential for maximizing light exposure. Measuring the length and width accurately ensures the wick fits snugly within the tube, preventing lighting issues or unnecessary light loss.

The assembly of the wick into the solar light tube also requires careful consideration. Secure attachment points help to guarantee stability and optimal light flow. Various techniques can be employed to fasten the wick within the tube, such as using adhesive methods or mechanical fasteners to ensure resilience under operational conditions.

4. MAINTAINING SOLAR LIGHT TUBE WICKS

Once constructed, maintaining the wick of a solar light tube becomes essential for ensuring ongoing performance and light diffusion. Regular cleaning is one critical factor. Accumulated dust and contaminants can diminish light absorption, thereby reducing overall efficiency. Carefully cleaning the wick not only improves light flow but also enhances the overall functionality of the solar light tube.

In addition to cleaning, regular inspections of the wick’s material for wear and tear are essential. Replacing worn-out sections of the wick when necessary ensures optimal performance. Adjustments can also be made based on seasonal variations, ensuring that the wick remains effective regardless of changing environmental conditions.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR LIGHT TUBE?

Solar light tubes, often referred to as solar tubes or sun tunnels, are installations designed to capture and channel natural sunlight into indoor spaces. These devices consist of a highly reflective tube that collects sunlight at the roof level and transmits it through a tube to illuminate dark spaces, thereby reducing reliance on artificial lighting. Typically comprising a dome for sunlight capture and a reflective tube for light transmission, solar light tubes serve both residential and commercial applications. Their effectiveness can significantly enhance indoor lighting, creating a vibrant atmosphere while contributing to energy savings and reduced carbon footprints. Various options exist to cater to different aesthetics, light requirements, and installation configurations.

HOW DOES THE WICK AFFECT LIGHT OUTPUT IN SOLAR TUBE LIGHTS?

The wick in solar tube lights plays a crucial role in determining the efficiency of light diffusion and overall brightness. A high-quality wick absorbs sunlight effectively and disperses it throughout the tube, enhancing illumination levels. Factors such as material type, thickness, and texture directly influence how efficiently light is transmitted. For instance, a well-designed cotton wick can improve light output due to its absorbent properties. In contrast, using inferior materials can lead to reduced luminosity and uneven light distribution. Crafting an effective wick involves careful consideration of these aspects to optimize performance, ultimately making a significant difference in the lighting experience indoors.

HOW OFTEN SHOULD I REPLACE A SOLAR LIGHT TUBE WICK?

The frequency of replacing a solar light tube wick largely depends on various factors such as material quality, environmental conditions, and usage patterns. Typically, high-quality materials can withstand years of use, but it’s advisable to conduct regular inspections for signs of wear, damage, or significant light output reduction. Generally, a good rule of thumb is to consider replacement every 3-5 years, especially if the wick shows evident deterioration or reduced efficiency. Additionally, seasonal changes and exposure to varying conditions may necessitate more frequent checks. Keeping the functionality of the wick in optimal condition not only maintains light output but also extends the lifespan of the entire solar light tube system.

The performance and longevity of solar light tube systems hinge significantly on the effective crafting and maintenance of their wicks. Quality material selection is paramount and should align with the specific lighting requirements and environmental conditions of the installation area. Engaging in precise construction techniques ensures that the wick fits well within the system, promoting stability and optimal light distribution. Ongoing maintenance practices are equally crucial, where regular inspections and cleaning can dramatically prolong the wick’s effectiveness, helping sustain high luminosity levels. Proper attention to detail throughout this process not only enhances the performance of solar light tubes but can also contribute to substantial energy savings and improved ecological footprints. For those venturing into the realm of solar technology, understanding the intricacies of wick construction and maintenance is vital for achieving optimal results and enjoying the numerous benefits of harnessing solar energy. With these practices in place, users can enjoy vibrant, natural lighting provided by their solar light tubes, improving indoor environments while fostering a commitment to sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-the-wick-of-solar-light-tube/