Creating a solar vertical junction box bracket involves several essential steps, including 1. Selecting appropriate materials, 2. Designing the bracket to accommodate specific solar panel configurations, 3. Fabricating the bracket accurately, and 4. Ensuring proper installation for optimal performance.

Each of these points deserves extensive exploration. Among them, designing the bracket is critical. This process necessitates consideration of the solar panel size, mounting requirements, and environmental factors such as wind and snow loads that may affect the bracket’s stability. A well-designed bracket enhances the efficiency and lifespan of the solar installation, maximizing energy production.

1. UNDERSTANDING THE COMPONENTS OF A SOLAR VERTICAL JUNCTION BOX BRACKET

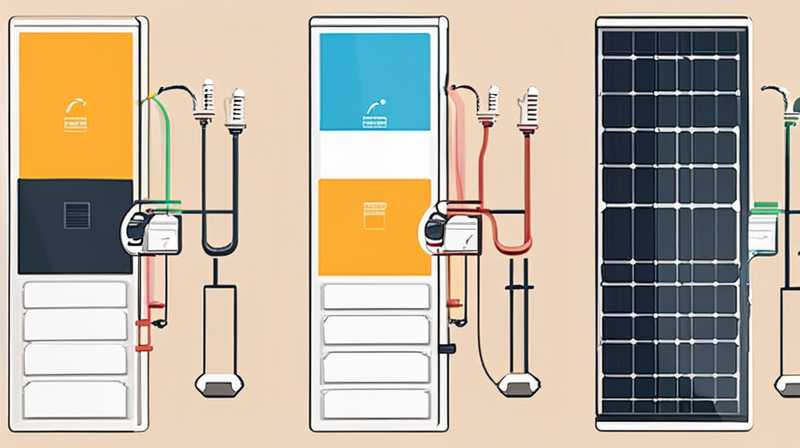

The foundation of creating an effective solar vertical junction box bracket lies in a thorough comprehension of its components and functions. Initially, one must recognize that this bracket serves as a supportive structure, facilitating the secure attachment of junction boxes to vertical surfaces adjacent to solar panels. Its primary role is to protect electrical connections from environmental elements while allowing easy access for maintenance or inspection.

The materials used in manufacturing such brackets are integral to ensuring longevity and durability. Aluminum and stainless steel are common choices due to their corrosion resistance and lightweight properties. The selected material has a substantial impact on the bracket’s overall performance and ability to withstand the rigors of outdoor conditions. Proper assessment of the terrain and climate where the solar installation is located will influence the choice of materials significantly.

2. DESIGNING THE BRACKET

The design phase of the vertical junction box bracket is perhaps the most intricate portion of the entire process. The bracket must provide ample support for the junction box while also remaining unobtrusive and aesthetically pleasing. This involves determining the bracket’s size, shape, and weight capacity, all of which must be aligned with the specifications of the solar panels being used.

Furthermore, consideration must be given to the vertical alignment and orientation of the junction boxes. Ideally, they should be positioned to facilitate easy wiring connections from the solar panels. Designers often use computer-aided design (CAD) software to create precise models that can be adjusted according to the unique requirements of each solar setup. Additionally, engineers may simulate various weather conditions to test the bracket’s resilience and ensure it meets both local and federal safety standards.

3. FABRICATION OF THE BRACKET

Once the design is finalized, the focus shifts to the fabrication process. This stage involves transforming the digital design into a physical product through various manufacturing techniques, including cutting, bending, and welding. Precision during fabrication is paramount, as any discrepancies could result in improper fit or insufficient strength.

Various fabrication methods may be employed based on the materials chosen. For instance, aluminum brackets are often extruded, while stainless steel may require more intensive machining processes. It’s crucial to ensure that all edges are smoothed and treated to prevent corrosion and mechanical failure. Quality control measures are essential during this stage to verify that each bracket adheres to the specified design criteria and safety standards.

4. INSTALLATION PROCEDURES

Following fabrication, the installation phase begins. Proper installation of the vertical junction box bracket is vital to the overall performance of the solar panel system. This phase involves a comprehensive inspection of the mounting surfaces to ensure they are capable of supporting the weight and stress placed upon them by the attached equipment.

Utilizing accurate tools and methods for installation not only prevents future complications but also guarantees that the system functions as intended. Specific attention must be paid to the alignment of the bracket to ensure it provides the correct angle for optimal solar exposure. Additionally, sealing techniques may be employed to enhance protection against the elements, further extending the life and performance of the junction box.

FAQs

WHAT MATERIALS ARE IDEAL FOR SOLAR VERTICAL JUNCTION BOX BRACKETS?

Choosing the right materials for solar vertical junction box brackets is essential to ensure durability and resistance to environmental conditions. Aluminum is highly regarded due to its lightweight nature and excellent corrosion resistance. It is particularly beneficial for installations in coastal areas where salt exposure may lead to corrosion. Stainless steel is another viable option, praised for its strength and longevity, ideal for heavier junction boxes or harsh climates.

However, selecting these materials also involves considering cost-effectiveness and performance requirements. Other factors include the manufacturing processes that can be difficult with certain materials, as machining steel may require extensive tooling and time. Ultimately, the decision should be aligned with the expected operational environment of the solar panels. Investing in quality materials typically results in fewer maintenance issues and a more robust system.

HOW DO I DETERMINE THE CORRECT SIZE FOR THE BRACKET?

Determining the correct size for a solar vertical junction box bracket requires a few critical considerations. First and foremost, one must assess the dimensions of the junction box itself, as the bracket needs to securely accommodate it without restricting access to the wiring. Furthermore, evaluating the mounting surface’s available space is also crucial, as it will dictate the design’s orientation and potential placement.

Further analysis involves calculating the load that will be applied to the bracket. Understanding the specific mounting arrangement and considering the solar panel configuration will influence bracket size. The guideline is to allow for some flexibility in design to account for future adjustments or additional equipment, providing a smart precaution to avoid constraints later. Ultimately, an accurately sized bracket contributes significantly to the overall efficiency and effectiveness of the solar installation.

WHAT ARE THE COMMON MISTAKES WHEN INSTALLING SOLAR VERTICAL JUNCTION BOX BRACKETS?

Several pitfalls may arise when installing solar vertical junction box brackets, each having implications on the efficiency and safety of the entire solar panel system. One of the most prevalent issues is improper alignment; misaligned brackets can lead to incorrect angles for solar exposure, directly affecting energy collection. Ensuring precise alignment during installation is crucial to achieving optimal performance levels.

Another common error involves neglecting to secure the brackets adequately. Failing to use appropriate fasteners or not tightening them sufficiently can lead to potential failure, especially in high-wind areas. Additionally, not considering thermal expansion and contraction can result in stress fractures or other forms of mechanical failure over time. Therefore, meticulous attention to detail during installation not only guarantees functionality but also ensures long-term reliability.

Achieving precision in creating and installing solar vertical junction box brackets warrants exceptional consideration across various aspects. The relevance of selecting suitable materials cannot be overstated, as they dictate the overall durability and longevity of the installation. Accurately designing the bracket is foundational—ensuring fit and functionality tailored to the specific requirements of the solar panels involved. Moreover, an effective fabrication process must translate the design into a tangible product while maintaining high-quality control standards. Finally, meticulous installation practices determine the practical success of the bracket and, by extension, the entire solar system. Thus, mastering each of these critical areas leads to creating an efficient and reliable solar energy solution.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-vertical-junction-box-bracket/