1. Making solar panels with wire mesh involves several crucial steps. 2. Begin by gathering all necessary materials, including wire mesh, photovoltaic cells, and solar panel encapsulating material. 3. Next, construct a frame using the wire mesh to hold the solar cells securely. 4. Incorporate appropriate wiring to connect the cells, ensuring maximum efficiency and functionality. 5. Finally, protect the setup with an encapsulation layer that features weatherproofing characteristics.

1. UNDERSTANDING THE COMPONENTS OF SOLAR PANELS

The construction of solar panels requires an understanding of various components and materials that contribute to energy efficiency. At the forefront are photovoltaic (PV) cells, which are responsible for converting sunlight into electrical energy. These cells can be made from materials like silicon, and they operate based on the photovoltaic effect. When light hits the cell, it knocks electrons loose, creating an electric current.

Wire mesh plays a critical role in holding the PV cells in place. It provides structural support while also allowing light to penetrate effectively. This material is lightweight yet sturdy, suitable for varying climatic conditions. Using wire mesh to secure PV cells enhances the durability of the entire assembly, subsequently improving longevity and efficiency in energy capture over time.

2. GATHERING NECESSARY MATERIALS

Collecting high-quality materials for solar panel construction is vital for achieving optimal performance. The primary components include photovoltaic cells, wire mesh, and encapsulation materials. The quality of photovoltaic cells directly influences the efficiency of the panel. There are various types available:

- Monocrystalline cells: Known for high efficiency, they require more silicon, resulting in higher production costs.

- Polycrystalline cells: These cells are less expensive and simpler to produce, but they also have moderately lower efficiency rates.

Beyond PV cells, robust wire mesh needs to be chosen, typically constructed from galvanized steel or aluminum to resist corrosion. The mesh size should be adequately chosen to accommodate the specific PV cell dimensions. Last but certainly not least, encapsulation materials such as ethylene-vinyl acetate (EVA) offer protection against environmental factors while maintaining transparency for optimal light capture.

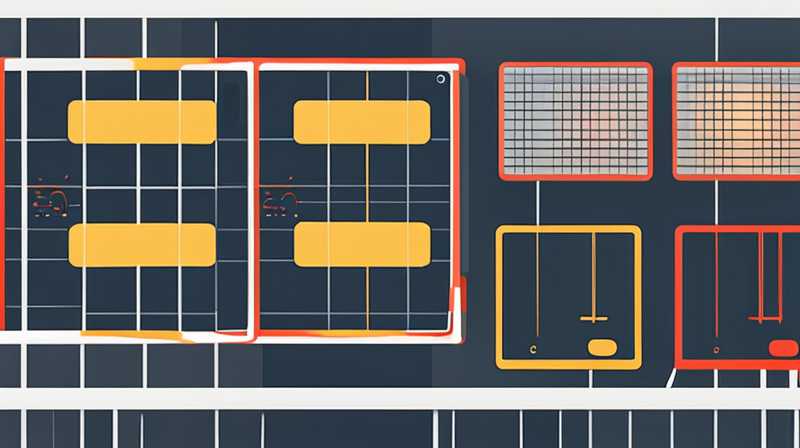

3. DESIGNING THE FRAME WITH WIRE MESH

The design phase is crucial in ensuring long-term functionality and efficiency of the solar panel. Crafting a frame using wire mesh involves securing the mesh tightly around the perimeter of the assembled photovoltaic cells. Careful measurements must be taken to ensure that each cell fits perfectly within the mesh without any gaps, thereby maximizing light exposure.

During installation, it is advisable to use durable connections, such as welding or sturdy clamps, to enhance the frame’s integrity. The wiring connections between the cells should also be arranged thoughtfully to maintain an organized and safe setup. Well-executed design not only secures the cells effectively but also allows for easy maintenance and replacement if needed. Ensuring a well-designed frame using wire mesh is, therefore, vital for the long-term success of the solar panel’s operations.

4. CONNECTING PHOTOVOLTAIC CELLS

Once the frame is ready, the next critical step involves connecting the photovoltaic cells. The wiring between cells is essential for the panel’s performance, thereby requiring meticulous attention. Copper wires are often preferred for their excellent conductivity. Depending on whether the cells are connected in series or parallel, different wiring patterns may be required.

In a series connection, the voltage increases, which is suitable for applications needing higher output. Conversely, a parallel configuration maintains a stable voltage but increases the current capacity. As part of this process, several key considerations need to be observed, such as the overall voltage requirements of the intended application, the total number of cells, and their arrangement. Thoroughly assessing these elements helps optimize the solar panel’s performance while reducing losses during energy conversion.

5. ENCAPSULATING THE SOLAR PANEL

The final step in the construction of solar panels involves encapsulation. This vital process protects the underlying photovoltaic cells from environmental impacts such as moisture, dust, and physical damage. Encapsulation materials, typically transparent, allow for maximum light transmission while providing a barrier against harmful elements.

Opting for EVA is a common choice due to its durability and effectiveness in sealing the solar cells. It should be applied under heat and pressure to activate its adhesive properties, creating a secure bond. Proper encapsulation not only enhances performance but also extends the lifespan of the entire panel, making it an essential phase.

Afterwards, a protective glass layer is often added on top to provide additional shielding and durability. This layer must be robust enough to withstand extreme weather conditions while maintaining transparency for optimal light capture.

6. TESTING AND OPTIMIZATION

Once the solar panel is fully assembled and encapsulated, it is essential to conduct rigorous testing for optimal performance. During this phase, each photovoltaic cell should be individually assessed for functionality. Voltage and current measurements can help ascertain that the cells perform effectively within the designed configuration.

In addition to efficiency testing, it is also vital to check for any signs of wear and tear on the connections and encapsulation. If issues are identified, appropriate adjustments should be made, including tightening connections or reinforcing encapsulation. Continued monitoring over time can provide insights into long-term performance, enabling timely maintenance and upgrades to maintain peak efficiency.

7. MAINTAINING SOLAR PANELS WITH WIRE MESH

Maintaining solar panels constructed with wire mesh is crucial for ensuring continuous operation and energy harvesting. A regular inspection routine, ideally once every few months, can reveal any potential issues requiring immediate attention, such as dirt accumulation or wear.

Cleaning the surface of the encapsulated panels is necessary to remove dust and debris that may obstruct sunlight. This cleaning is typically done using a soft cloth and approved cleaning solutions to prevent damage to the encapsulant and glass. Furthermore, checking wire connections and the integrity of the wire mesh itself is essential for safety and functionality, ensuring the longevity of the solar panel setup.

Additionally, it is advisable to monitor energy output regularly to track performance over time. If discrepancies between expected and actual energy outputs arise, troubleshooting steps should be implemented promptly. Preventive measures like these can help sustain high efficiency and uninterrupted energy generation, ultimately maximizing investment returns.

FAQS

WHAT MATERIALS DO I NEED TO MAKE SOLAR PANELS WITH WIRE MESH?

Creating solar panels using wire mesh demands several key materials. At the forefront are photovoltaic cells, integral for converting sunlight into energy. These cells come in various forms, including monocrystalline and polycrystalline types, with distinct efficiencies and costs. Additionally, wire mesh serves as a structural element, providing a framework for the cells while allowing light exposure. Common choices for wire mesh include galvanized steel or aluminum, known for corrosion resistance. Alongside these primary components, encapsulation materials such as ethylene-vinyl acetate (EVA) are essential for protecting the photovoltaic assembly from environmental hazards like moisture and dust. This layer warrants transparency to permit sunlight passage effectively. Lastly, soldering tools, copper wire for connections, and the support frame are necessary to complete the construction efficiently.

HOW LONG DOES IT TAKE TO ASSEMBLE SOLAR PANELS USING WIRE MESH?

The assembly duration of solar panels constructed with wire mesh can vary based on several factors, including the complexity of the design and the number of panels being built. On average, assembling one solar panel might take several hours. This period encompasses material preparation, cell arrangement, wiring, and encapsulation. Initially, preparing the materials, such as cutting the wire mesh and arranging the photovoltaic cells, could take roughly two hours. After designing the frame and securing the cells, connecting the wiring might require an additional hour or two, depending on the level of expertise. The encapsulation process, which involves applying EVA and ensuring air-free sealing, may add another hour. Lastly, testing and final adjustments to ensure peak efficiency could take yet more time—potentially stretching the entire project to one full day if everything is done meticulously. Thus, while assembling solar panels with wire mesh is generally straightforward, the total time investment is contingent on various factors.

CAN I REPAIR SOLAR PANELS MADE WITH WIRE MESH?

Repairing solar panels constructed with wire mesh is feasible; however, it necessitates careful assessment and specific tools. Depending on the nature of the damage—be it a cracked photovoltaic cell, a breach in the encapsulation layer, or a loose wire connection—different approaches are required. Should a particular photovoltaic cell be malfunctioning, it may be possible to replace just that cell, provided it is accessible within the mesh frame. The repair process typically involves carefully removing the protective layers, detaching the damaged cell, and replacing it with a new one. Ensuring that proper seals are re-established within the encapsulation layer is critical to maintaining long-term integrity after the repair. In cases where wire connections have come loose or corroded, those can often be re-soldered or replaced as needed, restoring normal operation. That said, consistent beforehand maintenance can significantly minimize the risk of requiring repairs, making regular inspections and cleaning paramount for sustaining optimal performance levels over time.

Creating solar panels with wire mesh is an intricate yet rewarding process. Throughout this undertaking, attention to detail is paramount. The journey begins with selecting high-quality components that assure longevity and efficiency. Developing a robust frame using wire mesh not only supports the photovoltaic cells but also facilitates effective light penetration. Additionally, careful attention to wiring ensures that energy conversion is maximized, while a resilient encapsulating layer protects against environmental threats. Regular maintenance and testing are crucial for sustaining performance, enabling solar panels to deliver renewable energy consistently. Observing these guidelines and processes fosters not only successful solar panel assembly but also reinforces the reliability of renewable energy systems. The future of energy lies in responsibly crafted installations capable of harnessing sunlight, making solar panel construction a vital component of the transition to sustainable energy sources. So let the light shine in; with the right techniques and materials, an effective solar panel is within reach.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-panels-with-wire-mesh/