To create solar panels from plastic pipes, one must follow a series of systematic steps which encompass understanding the materials, design concepts, construction techniques, and operational principles of solar energy conversion. 1. Understanding Materials, 2. Designing the Solar Panel, 3. Assembling the Components, 4. Installing the System, Each of these aspects plays a pivotal role in ensuring the solar panel functions effectively and efficiently, utilizing plastic pipes as a primary component.

1. UNDERSTANDING MATERIALS

The foundation of constructing solar panels from plastic pipes begins with identifying suitable materials. Plastic pipes, primarily made of polyvinyl chloride (PVC) or high-density polyethylene (HDPE), are lightweight and resistant to corrosion. This makes them excellent candidates for outdoor applications where exposure to various weather conditions is inevitable. The durability of these materials ensures longevity, minimizing the need for frequent replacements or repairs.

Additionally, solar cells or photovoltaic (PV) cells are crucial elements for energy conversion. Silicon-based solar cells are one of the most prevalent options, converting sunlight directly into electricity through the photovoltaic effect. These cells are typically arranged in series or parallel configurations to form a solar panel, allowing flexibility in power output based on the energy requirements. Understanding the interaction between plastic pipes and these solar cells is essential, as this relationship will dictate the efficiency and effectiveness of the solar panel system.

The design must also account for insulation materials and connectors that facilitate the integration of solar cells into the plastic pipe framework. Custom fittings and junction boxes may be required to ensure electrical connections remain safe and weather-resistant.

2. DESIGNING THE SOLAR PANEL

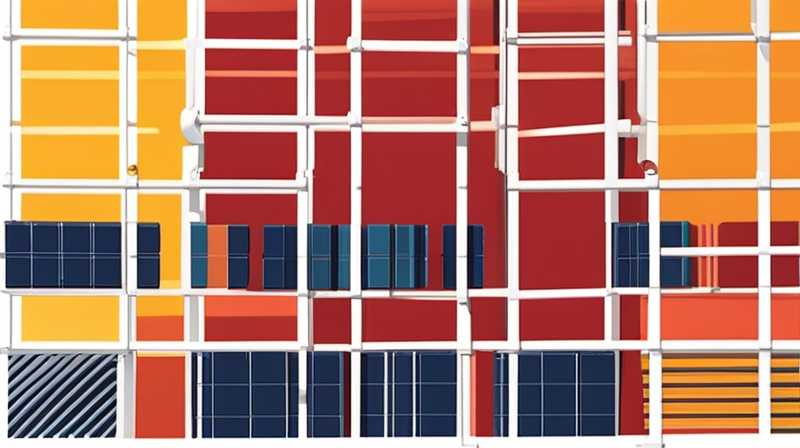

Designing the solar panel involves conceptualizing how plastic pipes will be utilized to house solar cells effectively. A common design approach features using clear acrylic or other transparent materials to cover the solar cells, allowing maximum sunlight exposure while protecting the components. The pipes can be arranged in a grid-like pattern to optimize the surface area, ensuring that each solar cell receives ample sunlight throughout the day.

Furthermore, the angle of solar panels is crucial for maximizing sunlight capture. Determining the optimal tilt angle based on geographical location is essential to enhance the efficiency of energy production. Fixed panels can be installed at a predetermined angle, or a tracking system can be employed to follow the sun’s trajectory, increasing overall energy generation.

Aerodynamic considerations should also be examined in the design phase to minimize wind resistance, especially for larger installations. Additional features, such as drainage holes, ensure that water does not accumulate, which can reduce system efficiency.

3. ASSEMBLING THE COMPONENTS

Once the design is complete, assembling the components is the next critical step. Starting with the plastic pipes, they should be cut to the desired lengths according to the design specifications, ensuring uniformity and compatibility with the solar cells. This initial step is crucial as it determines how well the overall structure will support the solar cell installation.

After cutting the pipes, the next stage involves attaching the solar cells. Each cell must be securely mounted within the pipes, using adhesive materials or brackets that allow for secure placement without obstructing sunlight. Conducting proper wiring is also paramount; connections between the cells should adhere to safety standards to prevent electrical issues.

Assembling the solar panel should also include integrating a charge controller and battery storage system to optimize energy collection and storage. This ensures that the energy harnessed during sunny periods can be utilized during cloudy days or at night.

4. INSTALLING THE SYSTEM

The installation process is equally pivotal in ensuring the solar panel functions effectively. Selecting an appropriate location with ample sunlight exposure is fundamental; areas free from obstructions like trees or buildings will enhance performance. Before installation, it is advisable to perform a site assessment to determine the ideal position and tilt angle.

When securing the solar panel system, it’s essential to ensure that all components—including the pipes, solar cells, and connectors—are held firmly in place. Ground mounts, roof installations, or pole mounts can be selected based on the available space and the intended application. Each mounting option has its advantages, with ground mounts typically providing easier access for maintenance.

Lastly, after installation, conducting a series of tests ensures the system is operating efficiently. Monitoring tools can track performance metrics, allowing adjustments to optimize energy collection and ensure long-term functionality.

FREQUENTLY ASKED QUESTIONS

HOW DO SOLAR PANELS MADE FROM PLASTIC PIPES COMPARE TO TRADITIONAL SOLAR PANELS?

Solar panels crafted from plastic pipes offer several distinct advantages over traditional silicon-based panels, yet they also present unique challenges. The weight of plastic-based systems, for instance, is significantly lower, making them easier to install and reposition. This lightweight property reduces strain on building structures where roof installations occur and allows for dynamic positioning to optimize sunlight capture. On the other hand, plastic solar panels may not reach the same efficiency levels as their traditional counterparts, as silicon panels generally have a higher energy conversion rate per square meter.

Moreover, plastic pipe solar panels can be constructed with a DIY approach, which might be appealing for eco-conscious individuals or communities seeking low-cost alternatives. The overall cost for materials tends to be considerably less than that of conventional panels, especially when sourced from reclaimed materials. Nonetheless, one must consider the lifespan and efficiency ratios; traditional panels typically provide longer warranties and performance guarantees that support long-term investment strategies.

WHAT ARE THE MAINTENANCE REQUIREMENTS FOR PLASTIC PIPE SOLAR PANELS?

Maintenance of solar panels made from plastic pipes is critical for sustained efficiency and performance. Regular inspections are recommended to identify any signs of wear, looseness, or obstructions that could hinder sunlight capture. Simple cleaning of the transparent covers is essential, as accumulated dirt or debris can significantly reduce energy output. Soft cloths or specialized solar panel cleaning solutions are advisable, avoiding harsh chemicals that could damage the materials.

Furthermore, ensuring that all electrical connections remain secure is crucial. Periodic checks of wiring and connectors help to prevent common electrical issues, such as shorts or corroded connections, which can compromise energy production. By performing regular maintenance, users can significantly extend the lifespan of their solar panel systems, ensuring that they continue to generate energy efficiently.

CAN I POWER MY HOME SOLELY WITH SOLAR PANELS MADE FROM PLASTIC PIPES?

The feasibility of powering an entire household with solar panels derived from plastic pipes depends on several factors, including household energy consumption, the size and efficiency of the solar panel system, and geographic location. Generally, it is possible to generate sufficient energy for domestic use through a carefully designed and scaled solar panel installation. However, achieving complete reliance on these systems may require substantial surface area dedicated to solar cells within the plastic framework.

To ensure maximum effectiveness, users might consider integrating a hybrid system that combines solar panels with another form of renewable energy, such as wind energy, to enhance output. Investing in energy-efficient appliances and reducing overall consumption can also help make solar energy systems more viable for homeowners looking to achieve energy independence. By balancing energy generation, storage, and consumption, many households can indeed transition to a sustainable energy model using innovative solar panel solutions made from plastic pipes.

The creation of solar panels utilizing plastic pipes is a groundbreaking endeavor that opens new avenues in renewable energy technology. By taking calculated steps and properly understanding materials, designs, assemblage, and installation, one can develop a functional and efficient solar panel system. Not only does this approach help in the sustainable management of resources, but it also empowers individuals and communities to harness solar energy for their use. As the world continues to find alternative energy sources to combat climate change, innovative solutions such as these will play a crucial role in fostering a greener future. Through experimentation and knowledge sharing, creating accessible forms of solar technology can undoubtedly pave the way for widespread adoption, making renewable energy an integral part of everyday life. The utilization of plastic pipes in solar power generation may represent one of many advancements in the ongoing transition toward sustainable living.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-panels-from-plastic-pipes/