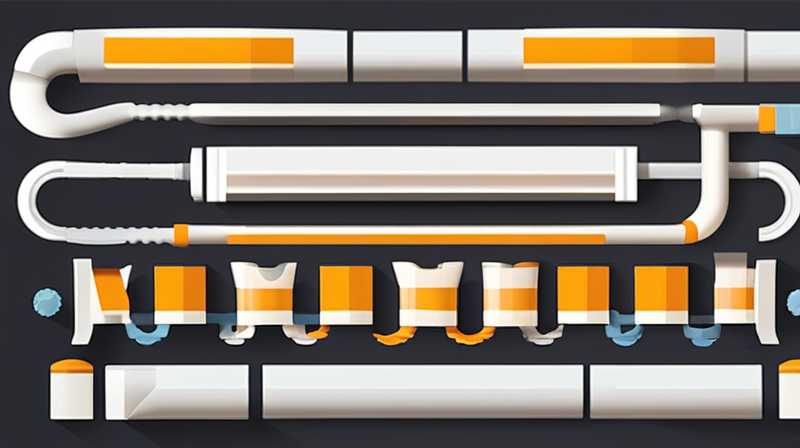

1. Joints for solar tubes can be constructed using several techniques focusing on efficiency and durability. Key considerations include: 1, selecting appropriate materials is crucial, 2, ensuring airtight seals enhances performance, 3, proper alignment maintains structural integrity, 4, utilizing professional tools improves workmanship. Denser explanations of each aspect are essential for successful implementation, especially regarding material selection. Choosing materials with high thermal stability like aluminum or specialized glass for joints can significantly influence heat absorption efficiency. The right choice affects both longevity and overall system efficiency.

1. MATERIAL SELECTION FOR SOLAR TUBE JOINTS

The foundation of successful joint construction for solar tubes lies in material selection. The materials that are used not only impact the integrity of the joints but also affect the overall performance and longevity of the solar heating system. For instance, materials such as aluminum and glass are highly recommended due to their excellent thermal conductivity and durability. Aluminum, being lightweight yet robust, allows for ease of installation while providing ample strength to withstand environmental stresses. On the other hand, glass provides a smooth finish that enhances solar absorption.

In addition to traditional materials, advancements in plastic composites have also gained popularity. Modern plastics can offer high resistance to thermal expansion and contraction, which is crucial for ensuring that joints maintain their integrity over varying temperatures. When selecting materials, it is essential to consider factors such as weather resistance, thermal efficiency, and compatibility with the existing system. Furthermore, the right adhesive or sealant should also be chosen to ensure that there are no leaks, which could compromise the system’s effectiveness. The materials selected for these joints ultimately reflect on the system’s reliability and efficiency in harnessing solar energy.

2. ACHIEVING AIRTIGHT SEALS

Once the appropriate materials have been identified, the next step involves achieving airtight seals. For solar tubes to work efficiently, it is vital that they do not lose heat or allow outside elements to penetrate the system. Sealing joints effectively is a critical component of the installation process. Common methods for sealing include the utilization of silicone caulk, rubber gaskets, or specialized joint tape designed for outdoor conditions. Each alternative offers a unique set of advantages, making it necessary to choose one that best suits the specific requirements of the installation.

For optimal results, surfaces must be properly prepared before applying any sealant. Clean, dry surfaces are essential for the adhesive properties of sealants to take effect. In addition, applying the sealant in a consistent manner can help achieve uniformity in the seal, contributing significantly to its effectiveness. Factors such as ambient temperature and humidity during installation can also play a role in the sealing process, so these should be considered beforehand. Ultimately, a well-sealed joint will minimize heat loss and enhance the overall effectiveness of the solar tube system, ensuring longevity and efficiency in harvesting solar energy.

3. PROPER ALIGNMENT OF TUBES

The importance of proper alignment cannot be understated in the construction of joints for solar tubes. Alignment is critical for ensuring that the tubes not only fit snugly together but also that they function optimally in absorbing sunlight. Misalignment can lead to gaps, which can compromise the system’s effectiveness and durability. When assembling the tubes, it is imperative that each section is lined up carefully, with the joints flush against one another. This attention to detail helps in maintaining the structural integrity of the system, reducing the likelihood of leaks or breaks over time.

Proper alignment also aids in creating an efficient flow of heat throughout the system. When the tubes are aligned correctly, it facilitates better circulation of the heated fluid, resulting in higher overall efficiency. Tools such as laser levels and alignment jigs can be instrumental in achieving the necessary precision during installation. It is advisable to regularly check for alignment throughout the installation process, as any slight misalignment can lead to significant issues later. In essence, the alignment of joints directly correlates with the performance and efficacy of the entire solar heating system.

4. USING PROFESSIONAL TOOLS FOR INSTALLATION

Engaging the use of professional tools is indispensable in ensuring that joints for solar tubes are assembled effectively and reliably. The use of high-quality tools contributes significantly to the quality of workmanship, reducing the chances of human error that could impact the performance of the system. For instance, specialized tube cutting tools help create precise joints that fit together seamlessly, while standard saws or haphazard methods can lead to jagged edges that compromise the integrity of the joint.

Professional tools also enhance safety during installation. Enhanced grip, better cutting mechanisms, and protective features minimize the risk associated with the handling of high-stress materials like glass and aluminum. Additionally, equipment such as torque wrenches can assist in ensuring that all fittings are adequately tightened to prevent loosening over time. The initial investment in professional tools will pay dividends in terms of both performance and durability of the solar tube system. Moreover, having the right tools ensures that installations comply with safety regulations, demonstrating commitment to quality and best practices.

5. MAINTENANCE FOR LONGEVITY

Regular maintenance practices are crucial for ensuring the longevity and efficiency of joints in solar tube systems. Periodic inspections help identify potential issues before they escalate, allowing for timely repairs and ensuring optimal performance. During these inspections, it is advisable to check for signs of wear or corrosion on joints, as these conditions can lead to leaks and compromised efficiency. Regular cleaning of the tubes and joints also plays a vital role in maintaining performance, as dirt or debris can hinder solar absorption.

Moreover, seasonal maintenance is essential to prepare the system for changing weather conditions. For instance, winterization procedures may involve sealing exposed joints or insulating sections that are particularly vulnerable to temperature fluctuations. In addition, keeping a close eye on the seals and any adhesive materials used is important, as changes in temperature can cause these materials to break down over time. Establishing and adhering to a diligent maintenance schedule ensures that solar tube systems can deliver their maximum potential throughout their service life, thereby enhancing long-term savings and sustainability.

6. COST-BENEFIT ANALYSIS OF STRONG JOINTS

When assessing the construction of joints for solar tubes, a cost-benefit analysis becomes necessary to appreciate the investment fully. While high-quality materials and professional tools may come with a higher upfront cost, they often lead to greater savings over time. Durable materials can enhance operational efficiency and reduce the likelihood of costly repairs, thus leading to lower maintenance expenses in the future. Additionally, a proper installation that adheres to best practices ensures that the system operates at an optimal level, thus delivering increased energy savings that can be substantial over the years.

Another factor to consider is the long-term environmental impact of a well-maintained solar system. Systems that operate efficiently not only reduce electricity bills but also minimize environmental footprints, aligning with sustainable energy practices. This long-term outlook underscores the importance of viewing initial expenses as investments in future benefits. Therefore, understanding the rationale behind quality choices in materials and workmanship can encourage better decision-making that aligns with both financial and ecological considerations.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BEST MATERIALS FOR SOLAR TUBE JOINTS?

Selecting the right materials for constructing joints in solar tube systems is of paramount importance. The most commonly recommended materials include aluminum, glass, and specialized plastics. Aluminum is highly regarded due to its lightweight nature coupled with remarkable strength; it is resistant to rust and corrosion and possesses excellent thermal conductivity, leading to improved energy efficiency. Glass, on the other hand, is favored for its smooth surfaces, which can significantly enhance solar absorption while being aesthetically pleasing.

Meanwhile, modern advancements in plastics have introduced high-performance polymer composites that exhibit exceptional temperature resistance and long-term durability. When evaluating these materials, it is essential to assess their compatibility with the overall system, thermal stability, and longevity. Each material has unique properties that can affect the solar tube’s efficiency, making it crucial to select a combination that optimally supports energy capture while ensuring durability through variable weather conditions. Ultimately, the best choices in materials will not only enhance functionality but also increase the lifespan of the entire system.

HOW DO I ENSURE MY SOLAR TUBE JOINTS ARE AIR-TIGHT?

To ensure that solar tube joints are airtight, meticulous attention must be paid to the installation process and the materials used. The first step is to thoroughly clean and prepare the surfaces where the joints will be made. Any dust, oil, or residues can significantly impair adhesion, leading to potential leaks. Once the surfaces are pristine, applying an appropriate adhesive or sealant is crucial. Common choices like silicone caulk are known for their excellent sealing properties and flexibility, making them ideal for outdoor installations where expansion and contraction occur.

After applying the sealant, it is crucial to allow it to cure fully according to the manufacturer’s recommendations before subjecting the joints to any stress. Regular inspections post-installation can help identify any potential weaknesses over time, allowing for early intervention. Implementing rigorous quality checks during the installation phase, including pressure testing where applicable, can further enhance the integrity of joints. By combining these practices, the likelihood of thermal losses or systemic failures due to improperly sealed joints can be minimized, ensuring the solar tube system operates at peak efficiency.

WHAT TYPE OF MAINTENANCE DO SOLAR JUNCTIONS REQUIRE?

Routine maintenance is essential for ensuring that joints in solar tube systems remain effective and durable over time. The first step in maintenance is regularly scheduled inspections, where a thorough check for signs of wear or damage is conducted. This includes examining the joints for any cracks, corrosion, or degradation of sealants. Identifying issues early can prevent them from escalating into more significant problems that could compromise the entire system.

Cleaning is another integral part of maintenance. Dust and debris accumulation can affect the performance of solar tubes, thereby requiring periodic cleaning to maximize solar absorption. Additionally, in regions with extreme weather changes, it might be necessary to undertake precautionary measures such as winterizing the system by insulating joints to withstand harsh conditions. Establishing a clear maintenance schedule tailored to the system’s specific environmental conditions will ensure long-term performance and reliability, ultimately leading to effective energy harnessing throughout the solar tube’s operational lifespan.

FINAL INSIGHT ON SOLAR TUBE JOINTS

When considering the construction and maintenance of joints for solar tubes, attention to detail is critical for ensuring optimal performance and longevity. Starting with material selection, making informed choices regarding which components to use can significantly influence the system’s efficiency. Achieving airtight seals and perfect alignment, utilizing high-quality tools during installation, and adhering to routine maintenance are all imperative elements that contribute to the system’s success. Although there may be an initial investment associated with quality materials and tools, the long-term benefits — both financially and environmentally — make it a worthwhile endeavor. A well-constructed solar tube system not only provides substantial energy savings but also advances sustainability goals, showcasing a commitment to harnessing renewable energy effectively. By prioritizing excellence throughout the installation and maintenance phases, users can ensure their solar tube systems achieve their maximum potential, making a lasting impact on both energy consumption and environmental stewardship.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-joints-for-solar-tubes-2/