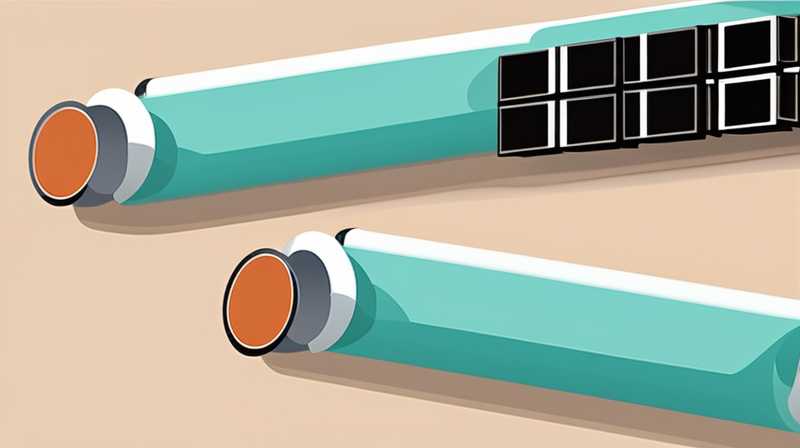

1. To create effective insulation board for solar pipes, follow these key steps: 1) Choose appropriate materials that have low thermal conductivity; 2) Measure and cut the insulation to fit the solar pipes; 3) Securely attach the insulation to the pipes using adhesive or mechanical fasteners; 4) Ensure seamless joints and a robust outer layer to prevent moisture ingress.

The first step in this process involves selecting the right materials, such as foam board or reflective foil. These materials aid in minimizing heat loss and ensuring optimal efficiency in solar pipe systems. A detailed understanding of the properties of insulation materials is crucial for maximizing thermal retention in solar applications.

1. MATERIAL SELECTION

Choosing the right materials for insulation boards is paramount. Different types of insulation materials possess unique characteristics that can greatly influence their performance. For instance, fiberglass is well-known for its excellent thermal resistance, while rigid foam offers enhanced durability and moisture resistance. Reflective foil, on the other hand, can significantly reduce heat transfer when placed adjacent to a heat source.

Moreover, assessing the thermal conductivity metric of each material can provide valuable insights. Materials with a low thermal conductivity value are beneficial for insulation purposes, as they can effectively reduce heat transfer. For solar pipes, materials such as polyurethane foam, polystyrene, and closed-cell rubber foam are commonly preferred due to their superior insulating properties. Furthermore, environmental considerations, such as sustainability and eco-friendliness of the insulation materials should also play a role in the decision-making process.

2. MEASUREMENT AND CUTTING

Once suitable materials have been chosen, precise measurement becomes imperative. Accurate dimensions ensure that the insulation board will fit snugly around the solar pipes, which is crucial for preventing heat loss. To achieve this, it is advisable to use a tape measure to determine the circumference and length of the pipes needing insulation.

Cutting the insulation boards to the correct size can be accomplished efficiently using a sharp utility knife or saw designed for the insulation material. It is essential to ensure that the cuts are clean and straight, as this will aid in achieving seamless joints when the materials are assembled. Any discrepancies in the size of the insulation boards can lead to air gaps that diminish the overall effectiveness of the insulation system.

3. ATTACHMENT TECHNIQUES

Securing the insulation boards to the solar pipes warrants careful attention. Several attachment methods can be utilized, with adhesive being one of the most common options. Choosing an adhesive suited for the material being used will enhance the adhesion and longevity of the insulation. In some scenarios, mechanical fasteners, such as screws or clamps, may be necessary to provide additional security.

Moreover, insulating the joints where sections of insulation meet is exceedingly important. Sealing joints correctly aids in maximizing the insulation’s effectiveness by minimizing potential paths for heat loss. Various sealing materials, including tapes designed for insulation purposes and caulking compounds, can be employed for this task, ensuring that the insulation remains intact over time.

4. FINISHING ELEMENTS

Completing the insulation assembly requires attention to detail concerning moisture and weather resistance. Installing a robust outer layer can protect the insulation board from environmental factors that may lead to degradation. Commonly, materials like weather-resistant wraps or protective membranes serve this function well.

Moreover, ensuring that all joints and seams are adequately covered is crucial. This preventive measure can safeguard against the infiltration of moisture, which can compromise the insulation’s thermal properties. Vigilance in executing these finishing touches can lead to a significantly enhanced lifespan and performance of the insulation system.

5. MAINTENANCE AND INSPECTION

Following the installation of insulation boards on solar pipes, routine maintenance should not be overlooked. Periodic inspections can help identify any signs of wear or damage that might arise over time. This includes checking for any moisture buildup, visible cracks, or any detachment of the insulation from the pipes.

Regular maintenance can also entail cleaning the surfaces of the insulation to remove any accumulated dirt or debris. A clean surface aids in maximizing the efficiency of the insulation, as contaminants can sometimes hinder its performance. Properly maintaining the insulation not only prolongs its life but also ensures that the solar pipe system remains highly efficient in energy retention.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF MATERIALS ARE BEST FOR INSULATING SOLAR PIPES?

Choosing the appropriate materials for insulating solar pipes is crucial for ensuring efficiency and longevity. Popular materials include closed-cell foam, fiberglass, and rigid foam boards. Each material has unique properties; for example, closed-cell foam offers exceptional moisture resistance and thermal insulation, whereas fiberglass is lightweight and provides good thermal resistance at a cost-effective price. It’s important to evaluate the specific temperature ranges and environmental conditions the insulation will face. Always select materials with low thermal conductivity values to minimize heat loss, and consider sustainability by opting for eco-friendly options when available.

HOW DO YOU SECURE INSULATION BOARDS TO SOLAR PIPES?

Securing insulation boards around solar pipes can be achieved through multiple methods including adhesives and mechanical fasteners. Adhesives should be compatible with the insulation material to enhance adherence. Common methods include applying insulation-specific adhesive or using double-sided tape to hold the boards in place before finalizing. Mechanical fasteners, such as screws or clips, may also be used for additional security, especially in applications with potential vibrations or shifts. Attention must be given to weatherproofing joints to prevent moisture ingress, which can drastically reduce insulation effectiveness.

HOW OFTEN SHOULD YOU INSPECT INSULATION ON SOLAR PIPES?

Inspecting insulation on solar pipes is essential for maintaining optimal performance. Routine inspections are recommended every 6 to 12 months, as seasonal changes can affect insulation integrity. During these inspections, look for signs of damage, such as visible cracks, moisture accumulation, or insulation detachment. Additionally, clean any dirt or debris building up on the surface, as this can hinder thermal performance. Proactively addressing issues discovered during inspections can extend the life of your insulation and improve the overall efficiency of your solar heating system.

The role of insulation board for solar pipes cannot be understated. Successfully creating and installing insulation requires meticulous attention to detail at every stage, beginning with rigorous material selection that aligns with specific thermal performance needs. The step of accurate measurement and cutting lays the groundwork for a hitch-free fit that facilitates optimal insulation. Beyond just physical assembly, choosing the proper attachment method and incorporating weather-resistant finishing elements confers durability and resilience against environmental impacts.

Moreover, engaging in maintenance protocols ensures that the insulation systems remain effective over time, capable of confronting challenges such as moisture load and temperature fluctuation. Investing time in developing a solid understanding of these procedures yields substantial dividends in achieving efficient solar pipe operations. Each aspect of the insulation process is intricately interconnected, forming a comprehensive framework that enhances the efficiency and longevity of solar thermal systems. Emphasizing preventative approaches through consistent inspection merges practicality with sustainability, affirming a commitment to energy efficiency in modern applications.

By embracing diligence in every stage, from initial design to post-installation checks, individuals ensure their solar heating systems perform at peak efficiency while also contributing positively to environmental sustainability. Innovatory approaches towards managing heat retention in solar applications are pivotal, as they not only serve functional needs but also align with broader goals of reducing reliance on non-renewable energy sources. This holistic understanding invites a proactive attitude towards renewable energy applications, maximizing their effectiveness and reinforcing the commitment to innovative solutions in energy conservation and efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-insulation-board-for-solar-pipes/