1. Constructing a solar dryer requires several essential materials, careful design, efficient airflow, effective insulation, and thoughtful placement. Solar dryers harness the sun’s energy to effectively dry food items, preserving their nutritional value and enhancing shelf life. 2. Understanding the specific principles of solar energy capture and moisture removal is crucial for effective operation. 3. Additionally, incorporating quality materials can significantly impact the efficiency and longevity of the dryer. 4. Maintenance and safety measures must be consistently practiced to ensure optimal performance.

1. SELECTING MATERIALS

Creating an effective solar dryer begins with selecting appropriate materials. The primary components generally include a suitable frame, drying trays, a transparent cover, and insulation. Wood or metal may serve as the frame, with the choice depending on durability and environmental conditions. The drying trays should preferably be made from food-grade materials, such as stainless steel or BPA-free plastic, to ensure safety.

Moreover, a transparent covering like glass or UV-resistant plastic is essential to allow sunlight to penetrate while keeping moisture from escaping too rapidly. This capstone is critical as it aids in heat retention inside the dryer. Insulation material can be sourced from polystyrene boards or foam to minimize heat loss, potentially increasing efficiency.

The selection process could impact the longevity of the solar dryer, making it crucial to invest time in assessing various options. Proper materials can elevate the dryer’s functionality, allowing for better energy capture and moisture evaporation.

2. UNDERSTANDING DESIGN PRINCIPLES

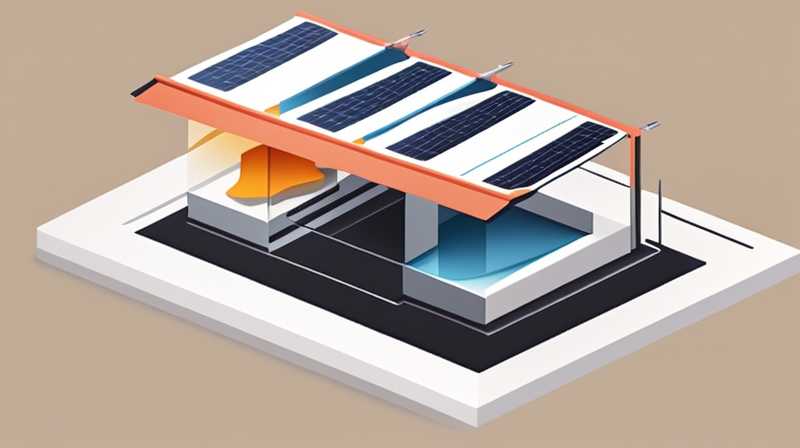

Experience with basic design principles can significantly influence the effectiveness of a solar dryer. A well-thought-out design incorporates elements that enhance airflow, natural convection, and heat absorption. One efficient configuration is the box-type solar dryer, which is usually rectangular or square. This shape allows for maximized surface area to collect sunlight, and its enclosed structure ensures better heat retention.

Considerations in terms of airflow are just as important; ensuring that there are exit points for moisture while allowing fresh air circulation can create a balanced environment. Natural convection currents can help facilitate airflow, allowing moisture vapor to escape while drawing in fresh air.

In addition, placing the solar dryer at an angle to maximize sunlight exposure is another essential design principle. The positioning can determine how efficiently solar radiation penetrates the drying area. Ideally, orienting the dryer towards the equator enhances its overall performance.

3. ASSEMBLING THE SOLAR DRYER

Once suitable materials and design elements are prepared, the next crucial step involves actual assembly. Taking accurate measurements is foundational; this ensures that every part aligns correctly, allowing for optimal airflow and heat retention. Following a systematic approach can mitigate errors that may arise during construction.

Begin by constructing the frame, verifying that it is both sturdy and waterproof to withstand various weather conditions. After the frame is built, the transparent covering must be securely fitted, ensuring that it is sealed correctly to prevent moisture leakage. Drying trays should be arranged strategically to promote even exposure to sunlight and facilitate airflow.

As assembly progresses, it is essential to maintain attention to detail, evaluating for gaps that might allow heat loss or moisture ingress. Regular quality checks during this phase can positively impact the overall efficacy. Ultimately, a well-assembled solar dryer can offer years of reliable use.

4. MAINTAINING THE SOLAR DRYER

Long-term operational efficiency of a solar dryer hinges significantly on proper maintenance. Regular cleaning is imperative; a film of dust or dirt on the transparent cover can significantly diminish sunlight penetration. Utilizing mild detergents and soft cloth for cleaning can preserve the integrity of the materials used.

Another important aspect includes inspecting components for wear and tear. Checking joints, seals, and structural integrity ensures that the dryer functions optimally over time. Replacing any damaged parts promptly can prevent further complications that may hinder performance.

It’s also advisable to evaluate the drying environment regularly. External factors like excessive humidity or temperature fluctuations could impact drying efficiency. Being aware of these variables enables more effective food preservation efforts.

FREQUENTLY ASKED QUESTIONS

WHAT FOODS CAN BE DRIED USING A SOLAR DRYER?

Solar dryers are versatile and can be used to dry a wide range of food items. Fruits such as apples, peaches, and tomatoes are common candidates due to their relatively high sugar content, which aids in natural preservation. Vegetables like carrots, bell peppers, and various herbs also perform well under solar-drying processes. The key lies in the moisture content; meats and fish can be dried but are often better accommodated through controlled dehydration settings to mitigate bacterial growth.

Furthermore, knowing the right temperature settings is critical for food safety. Maintaining temperatures between 130-160°F typically yields satisfactory results for most food items. Monitoring humidity levels is also essential; lower humidity enables faster drying, thereby enhancing the overall quality of the final product.

HOW LONG DOES IT TAKE FOR FOOD TO DRY IN A SOLAR DRYER?

The duration necessary for food drying may vary based on several factors. Typically, most items will take anywhere from 5 to 12 hours to completely dehydrate, contingent upon initial moisture levels and ambient conditions. Ideally, sunlight intensity, humidity, and airflow all play critical roles in determining the drying time.

For instance, thinly sliced fruits will dry much quicker compared to whole fruits. Meats and fish require significantly longer drying periods, often necessitating rigorous monitoring to ensure that they reach safe moisture levels. It is equally vital to understand that nights and overcast days will slow down the drying process, necessitating further planning.

HOW CAN I ENSURE EVEN DRYING IN A SOLAR DRYER?

To achieve uniform drying, several best practices can come into play. Regularly rotating trays throughout the drying process can distribute heat evenly. It is also useful to cut food into similarly sized pieces, as this facilitates even moisture loss. Maintaining adequate spacing between trays ensures optimal airflow, further enhancing drying effectiveness.

Monitoring the drying conditions consistently helps in timely adjustments; recognize that even a few degrees difference can alter the drying efficiency significantly. Using a thermometer can provide insight into internal temperatures, allowing for informed decision-making.

5. UNDERSTANDING SAFETY MEASURES

When engaging in the construction and use of a solar dryer, one must prioritize safety. Protecting oneself against potential hazards is paramount in ensuring a smooth operation.

For starters, handling tools and materials with care decreases the risk of accidents during construction. It is advisable to wear appropriate protective gear, including gloves and goggles, to safeguard against any injuries.

Furthermore, when drying certain food items, awareness of food safety guidelines is critical. Contamination can occur if raw foods come into contact with dried foods; separation of these processes minimizes this risk. Lastly, constantly monitoring moisture levels is essential for preventing mold growth, human error can lead to serious health issues.

The establishment of a solar dryer can serve multiple purposes: environmentally friendly food preservation, promoting sustainable practices, and achieving energy efficiency. Individuals can actively contribute to reducing food waste while embracing a cost-effective solution for their drying needs. By understanding the intricate elements associated with material selection, design principles, assembly, maintenance, and safety, anyone can create a functional and effective solar dryer. This process not only ensures the longevity of the drying apparatus but also enhances its utility and overall performance. As awareness of sustainable living continues to grow, solar dryers stand out as a practical and beneficial tool for individuals and communities alike.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-a-solar-dryer/