1. Performing routine inspections is essential for the longevity of solar cell valves, 2. Regular cleaning prevents build-up and ensures efficiency, 3. Environmental factors influence performance, 4. Replacing ineffective components is crucial for optimal functionality.

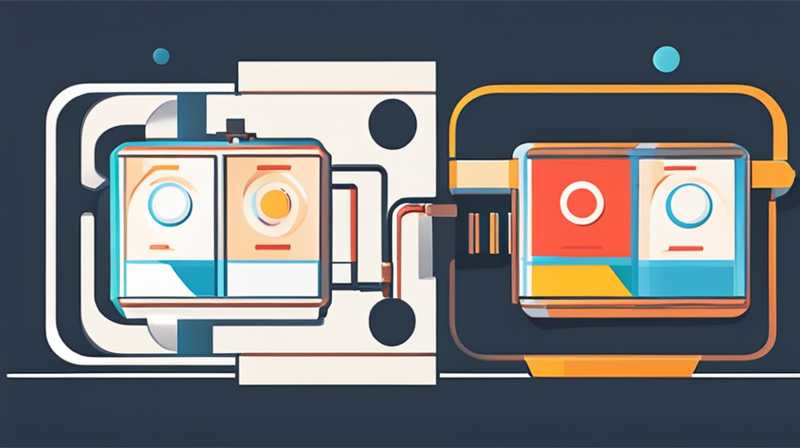

Maintaining solar cell valves is a multifaceted process that requires diligence and attention to detail. These valves play a vital role in the efficiency of solar power systems by regulating the flow of fluids within the system. Proper upkeep not only extends the lifespan of these components but also optimizes the overall functionality of solar energy installations. Regular inspections, timely cleaning, consideration of environmental conditions, and component replacement are critical aspects that contribute to the effective maintenance of solar cell valves.

1. ROUTINE INSPECTIONS

Routine inspections form the bedrock of effective maintenance practices for solar cell valves. This involves assessing the physical condition and functional performance of valves at scheduled intervals. Inspecting for signs of wear and tear, leaks, or corrosion can prolong the life of the valve and ensure it operates at peak efficiency. Additionally, it’s essential to evaluate how well the valve is integrating with the rest of the solar energy system. Regular checks allow for early detection of potential issues, which can prevent more significant failures down the line.

During inspections, attention should focus on various components, including seals, springs, and actuators. Seals are critical for maintaining the integrity of the valve, and any degradation can lead to leaks. Springs should be examined for tension and functionality, as these can affect how well the valve opens and closes. Actuators must also be tested, as they control the movement of the valve based on signals from the solar energy system. Consistently documenting findings during these inspections is integral for tracking changes and identifying patterns that may indicate underlying problems.

2. REGULAR CLEANING

Regular cleaning routines are paramount for maintaining the efficiency of solar cell valves. Outdoor installations are often exposed to dirt, dust, and other environmental contaminants that can accumulate over time. A clean valve ensures uninhibited fluid flow, which is necessary for optimal system performance. Conducting thorough cleaning involves using appropriate cleaning solutions and tools to avoid causing damage to the valve components while effectively removing any build-up.

It’s vital to employ a systematic cleaning approach. Start by disconnecting the valve from the system, which allows for safe handling during the cleaning process. Use soft brushes and non-corrosive cleaners to eliminate debris without scratching surfaces. After cleaning, thorough rinsing is essential to remove any cleaning agent residues that could affect the valve’s performance. Lastly, ensure the valve is completely dry before reconnecting it to the system to prevent moisture from causing mechanical failure.

3. ENVIRONMENTAL FACTORS

Environmental conditions play a significant role in the performance of solar cell valves. Factors such as temperature, humidity, and exposure to harmful elements can affect the materials out of which the valves are constructed. While some valves are designed to withstand various conditions, others may require protective measures such as enclosures to prevent degradation. An understanding of how local environmental factors interact with the valve is crucial for maintenance planning.

Temperature fluctuations can lead to material expansion and contraction, a phenomenon that can place stress on seals and other components. Excessive humidity can contribute to corrosion, while exposure to sunlight can degrade plastic components over time. Regular assessments with a focus on environmental effects can guide maintenance practices, ensuring that valves remain functionally sound despite adverse conditions. It may also be necessary to employ climate-resistant materials or use insulating covers as remedial measures.

4. REPLACING INEFFECTIVE COMPONENTS

Over time, certain components of a solar cell valve may become ineffective, necessitating replacement to maintain overall efficiency. Monitoring the performance of individual parts is essential, as delays in replacement can lead to system inefficiencies that are expensive to rectify. Common components requiring replacement include seals, spring mechanisms, and even the valve body itself, depending on circumstances.

When signs of failure are detected, component replacement should happen swiftly. Using original parts designed for specific valve models is vital, as compatibility issues can arise with generic components. This process not only involves removing the ineffective part but also conducting compatibility assessments for the new part to ensure seamless integration into the existing system. Additionally, documenting the maintenance history, including any replacements made, will offer valuable insights into the operational lifecycle of the valve.

FAQS

WHAT SIGNS INDICATE THAT A SOLAR CELL VALVE NEEDS MAINTENANCE?

Common indicators that signal required maintenance of solar cell valves include noticeable leaks, abnormal noises during operation, and reduced efficiency in fluid flow. Specifically, leaks can result from worn seals or loose fittings; addressing them promptly prevents further issues and system inefficiencies. Noisy operations often signify problems with the moving components or a misalignment with the system, while operating under reduced efficiency levels suggests internal blockages or malfunctions. Maintaining an awareness of these signs will allow for timely intervention, ensuring the stable performance of solar energy systems.

HOW OFTEN SHOULD SOLAR CELL VALVES BE INSPECTED AND CLEANED?

The frequency of inspections and cleanings largely depends on environmental conditions and the operational load of the solar power system. Generally, a biannual inspection is advisable, while cleaning can occur more frequently, particularly in dusty or high-pollution areas. For instance, following major weather events or periods of heavy rainfall, conducting inspections and cleanings would be prudent. Regular maintenance and cleaning not only assist in keeping the valves functional but also contribute to the overall health and efficiency of the solar energy system.

WHAT TOOLS AND MATERIALS ARE REQUIRED FOR SOLAR CELL VALVE MAINTENANCE?

The tools and materials necessary for effectively maintaining solar cell valves include standard wrenches for adjusting components, soft brushes for cleaning, and non-corrosive cleaning solutions to ensure safe removal of debris. Additionally, lubrication products designed for valve mechanisms may be required during the inspection to ensure smooth operation. It is also advisable to have replacement parts on hand, including seals and springs, to replace defective elements without delay. Furthermore, keeping a maintenance log and checklist can help in staying organized and systematic in the upkeep of the valves.

Maintaining solar cell valves is an intricate undertaking that combines several critical aspects of attention to detail. Performing routine inspections helps in identifying potential issues early on, which serves to preserve the functionality of these integral components. Regular cleaning removes build-up that could impede performance, ensuring a smooth flow of fluid essential for efficient operation. Environmental factors impact the performance of solar valves; therefore, awareness and considerations regarding such elements are paramount. As certain components become ineffective due to wear over time, prompt replacement is vital for maintaining the system’s health. By understanding and implementing strategies around these key areas, solar energy systems can achieve enhanced longevity and efficiency. Ultimately, a proactive approach to maintenance not only promises immediate benefits but also contributes to long-term sustainability in renewable energy practices. Regularly prioritizing these aspects fosters resilience against potential operational challenges, reaffirming the commitment to harnessing energy effectively while preserving essential components like solar cell valves. Following these outlined guidelines will provide substantial protection and preserve functionality, so investing the time in regular maintenance pays off significantly.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-maintain-solar-cell-valve/