To lengthen the solar charging panel cable effectively, one can follow these steps: 1. Choose an appropriate gauge wire, 2. Use connectors to facilitate the extension, 3. Ensure waterproofing of connections, 4. Consider voltage drop when selecting cable length. The most crucial aspect, choosing the right gauge wire, is essential to prevent overheating and power loss as longer cables can increase resistance.

1. UNDERSTANDING SOLAR PANEL WIRING

When dealing with solar panel systems, the wiring connecting the panels to the charge controller and battery is fundamental. The efficiency of energy transfer from solar panels to the batteries largely depends on the quality and length of the wire used. Longer wires can lead to a phenomenon known as “voltage drop,” where the energy lost in wiring results in decreased efficiency for the solar energy system. Therefore, it is crucial to understand the implications of lengthening the cable and the factors that come into play.

Moreover, the choice of wire gauge is pivotal. Thicker wires allow for less resistance compared to thinner wires, meaning less energy is lost during transmission. The American Wire Gauge (AWG) system is used to determine the appropriate gauge for electrical wiring. The lower the AWG number, the thicker the wire. For solar applications, appropriate wire sizes depend on the total length of the cable, the total load expected, and the overall system voltage. The wire’s material—usually copper or aluminum—also affects its performance and should be taken into account when selecting an appropriate wire.

2. FACTORS TO CONSIDER WHEN LENGTHENING CABLES

Several key considerations must guide the decision-making process when extending solar panel cables. One critical aspect is voltage drop. As noted earlier, longer cables can lead to increased voltage drop, which diminishes the efficiency of energy transfer. It is vital to calculate the potential voltage drop to ensure that the solar charging system remains effective. Calculations can be performed using a voltage drop calculator available online, or formulas that account for wire length, current, and wire gauge can be applied to quantify this aspect accurately.

In addition, environmental factors must also be taken into account. Exposure to elements—such as rain, sunlight, and extreme temperatures—can affect the durability and longevity of the cables. Selecting weather-resistant materials or ensuring that cables are adequately protected from harsh conditions will be essential for maintaining system integrity over time. This includes considering the insulation type and ensuring that any connectors used are also rated for outdoor use.

3. CHOOSING THE RIGHT WIRE GAUGE

Utilizing the appropriate gauge wire cannot be overstated when lengthening solar panel cables. Selecting the right gauge ensures that the system functions effectively and safely. For instance, when the cable length exceeds 50 feet, it may be necessary to upgrade to a lower gauge to offset the effects of resistance. Many solar panel manufacturers provide specifics on the wire sizes required for their systems, so checking the manufacturer’s recommendations is often a good initial step.

For higher wattage systems, particularly those intended for residential use or off-grid applications, thicker cables are generally recommended. This reduces the likelihood of overheating and potential fires, which can occur from overloading. The installation may also require the knowledge of how to splice cables securely or use connectors that can handle the increased gauge size safely.

4. CONNECTING AND EXTENDING CABLES

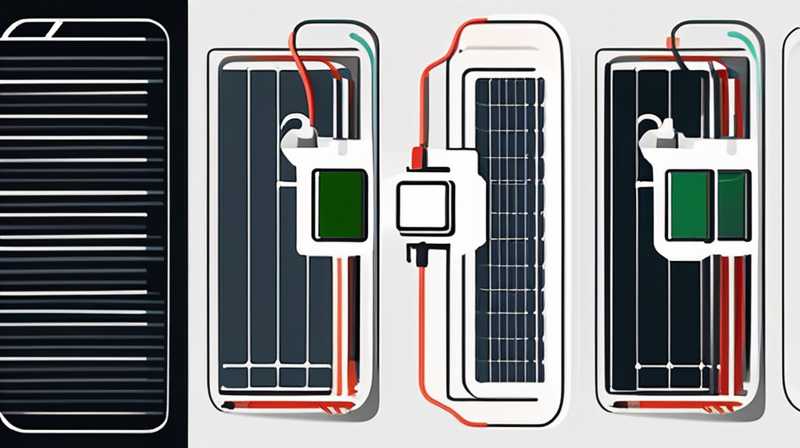

Once the appropriate gauge wire has been selected, the next step involves the actual process of connecting and extending the cables. This usually involves splicing cables together using connectors, which can come in various forms, such as soldered connections, crimped connections, or the more common barrel connectors. Each type of connection has its advantages and potential pitfalls, so the choice should be made based on specific needs, accessibility, and the resources available.

Waterproofing is critical. Any splice or connection needs to be insulated properly to prevent arcing, element penetration, and corrosion over time. Heat shrink tubing can be used in conjunction with connectors to seal the joints effectively. Additionally, electrical tape may offer another layer of protection, but should not serve as the primary method for waterproofing. Ensuring that connections are completely sealed will prolong the overall lifespan of the longer cable configuration and promote system reliability.

5. INSTALLATION CONSIDERATIONS

Beyond the basic connection of extended wiring, installation involves additional practical considerations. Proper routing of cables is essential to avoid potential physical damage from factors such as foot traffic or harsh weather conditions. Cables should ideally be placed in protective conduits, or in buried trenches if necessary, to safeguard them from damage while maintaining a clean installation.

Moreover, ensuring that cables do not create any tension or strain at connection points is crucial. Stress on connections can lead to premature failures, so always organize the layout of cables neatly, minimizing bends and twists. Using cable ties or clamps to secure them along the mounting surface can help keep everything tidy and secure, reducing the risk of accidental snags or damage.

6. TESTING AND MONITORING SYSTEM PERFORMANCE

After installation, conducting thorough tests of the solar charging system is vital to ascertain that everything is functioning correctly and efficiently. Monitoring tools should be used to determine whether the voltage drop is within acceptable limits and that the batteries are charging as expected. This monitoring includes checking the output from the solar panels, ensuring that current levels correspond with the expected results.

Setting up a regular maintenance plan becomes necessary to ensure ongoing system performance, especially after extending cables. Periodically inspecting connections and cables for any signs of wear or damage will significantly contribute to the longevity and reliability of the solar charging system. Documenting any changes or upgrades also provides insight into system performance over time, which can assist in future modifications or troubleshooting.

7. MAINTAINING AND REPLACING CABLES

In time, even properly installed cables may need maintenance or replacement. Factors such as wear and tear, exposure to the elements or pests, and evolving energy needs can influence this necessity. Regular visual inspections, as well as testing for conductivity and insulation integrity, will inform when cables need to be serviced or replaced.

When replacing cables, it is vital to re-evaluate the initial decisions made regarding wire gauge and environmental factors. Given technology improvements, it may be possible to upgrade to better materials that enhance performance and longevity. Always ensure that any new installation adheres to current best practices and guidelines, beginning from the selection of materials to installation and monitoring.

FAQS

HOW DOES VOLTAGE DROP AFFECT SOLAR PANEL PERFORMANCE?

Voltage drop occurs when there is a reduction in voltage from the source to the load due to resistance in the wire. In solar panel systems, extended cable lengths can cause this drop, resulting in reduced efficiency and power output. This impact can lead to underperformance of the entire solar energy system, especially if the drop is excessive. To mitigate this, selecting the appropriate wire gauge to lower resistance is crucial, as well as minimizing the distance between the solar panels, charge controller, and batteries when possible. Regularly monitoring voltage levels can help detect issues early, thereby safeguarding against performance losses.

WHAT MATERIALS ARE IDEAL FOR SOLAR PANEL CABLES?

Copper and aluminum are the two most commonly used materials for solar panel cables. Copper is frequently preferred due to its superior conductivity, which translates to less energy loss during transmission; however, it is also more expensive. Aluminum, while cheaper and lighter, requires a larger diameter to match copper’s conductivity. Additionally, it is essential to ensure that cabling is insulated effectively and rated for outdoor use, to withstand various environmental factors such as UV exposure and moisture. Proper insulation materials designed for solar applications will help maintain system integrity over the long term.

CAN I USE REGULAR ELECTRICAL CABLE FOR SOLAR PANELS?

Using regular electrical cable for solar panel systems is not advisable. Typical electrical cables may lack the necessary insulation ratings and durability to withstand outdoor conditions, such as UV exposure, moisture, and extreme temperature fluctuations. Solar cables are specifically designed to endure environmental challenges, have improved flexibility, and possess higher temperature tolerances. Employing inappropriate cables can lead to safety hazards, including overheating and potential fire risks, along with diminished system performance. Always utilize cables that conform to specified standards for solar applications to ensure safety and reliability.

Extending the solar charging panel cable requires careful consideration and execution of several crucial steps. One must choose the right gauge wire to minimize voltage drop, understand environmental impacts, use quality connectors, and maintain an organized installation for optimal performance. Proper testing and maintenance post-installation are essential to ensure that the modifications yield a reliable and efficient solar energy system. Moreover, understanding the complexities involved in connecting and managing solar charging systems enhances the longevity and effectiveness of renewable energy solutions. By focusing on careful planning and execution, one can expand and adapt existing systems to suit both present and future needs effectively. Thus, a thorough approach to upgrading and maintaining solar panel wiring can offer sustainable benefits, empowering users to capitalize on green energy resources for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-lengthen-the-solar-charging-panel-cable/