To assess the quality of solar ball valves, one must consider several critical aspects. 1. Material composition influences durability and performance, 2. Certification demonstrates adherence to standards, 3. Design affects functionality, and 4. Manufacturer reputation plays a role in reliability. Let’s delve deeper into these factors to comprehend their significance.

1. MATERIAL COMPOSITION AND ITS IMPACT ON QUALITY

The materials utilized in the production of solar ball valves significantly influence their overall quality and operational longevity. Common materials include brass, stainless steel, and PVC, each possessing distinctive properties and advantages.

Brass, for instance, is often prized for its resistance to corrosion and its excellent mechanical strength. Brass solar ball valves can operate effectively in a variety of environments, offering durability and a long operational lifespan, particularly in applications where temperature fluctuations occur. However, it is essential to ensure that the brass used is of high-grade quality, as lower grades may lead to premature wear or failure.

On the other hand, stainless steel offers superior resistance to rust and oxidation, making it an ideal choice for installations in harsher conditions where exposure to water or aggressive chemicals may be prevalent. These valves tend to have higher thermal stability, contributing to their longevity. Furthermore, the manufacturing process itself plays a pivotal role; valves that are forged often display greater strength compared to those that are cast, due to the homogeneous structure achieved during forging.

The choice of PVC is frequently associated with lightweight applications, offering a cost-effective solution, but it may not withstand high-pressure conditions as effectively as metals. Understanding the specific requirements of the application will guide the choice of material, ensuring optimal performance under the intended conditions.

2. CERTIFICATION AND INDUSTRY STANDARDS

Having proper certification is paramount when evaluating solar ball valve quality. Certifications such as those from the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO) signal that the product has undergone rigorous testing and meets specific safety and performance standards.

The importance of these certifications cannot be overstated; they provide customers with confidence that the valves will perform as required. In regulated industries, compliance with such standards is not merely a recommendation but a necessity. For instance, valves utilized in commercial settings often require adherence to legal guidelines to ensure safety and functionality.

Furthermore, certification often covers a range of testing procedures, such as pressure testing, which evaluates how the valve responds to internal pressure without leaking. This testing ensures that even under extreme conditions, the valve will maintain integrity. Looking for products that meet these standards can drastically reduce the risk of failures and prolong the service life of the equipment in which they are installed.

3. FUNCTIONAL DESIGN CONSIDERATIONS

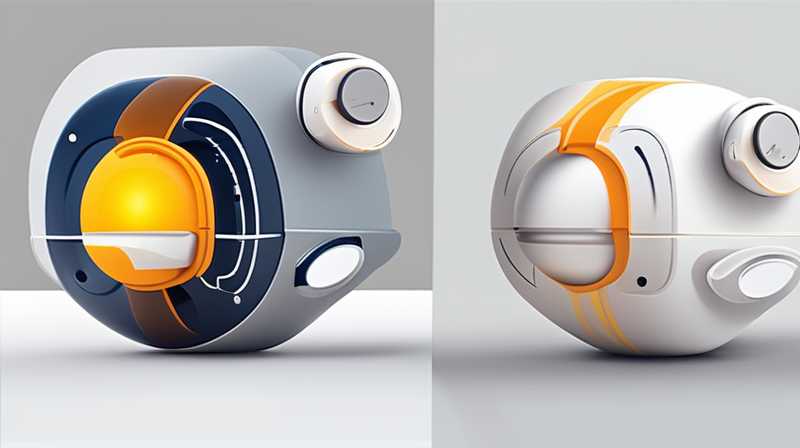

The design of solar ball valves can dramatically affect their performance. A well-engineered valve will offer smooth operation while minimizing potential leaks. The primary components concerned include the ball itself, seals, and the valve body.

Ball design is critical, as it needs to provide adequate sealing while allowing for easy manipulation. The surface finish of the ball can influence how well it seals against the seat. A polished surface will have fewer imperfections, which can prevent leaks. Additionally, the size of the ball relative to the valve body must be appropriate to ensure that the flow rate can be commanded effectively without excessive turbulence.

Seals are another essential element of valve design. Materials used for seals, such as rubber or Teflon, should be selected carefully depending on the operational environment. For example, in applications that experience extreme temperatures, the seal material must withstand these conditions without degrading. The method of seal insertion and retention also matters, as improperly installed seals can lead to significant leaks and malfunctions.

Valve body design should also not be overlooked. The overall shape and configuration affect not only the flow dynamics but also ease of installation and maintenance. Valves with a streamlined design might provide less resistance to flow, thus improving efficiency. Furthermore, incorporating features such as easy-access ports for maintenance can enhance usability significantly.

4. MANUFACTURER’S REPUTATION AND RELIABILITY

Evaluating the reputation of a manufacturer before purchasing solar ball valves can yield insights into their overall quality and reliability. A reputed manufacturer often has a history of producing durable products that meet or exceed customer expectations, which is reflected in testimonials and feedback from previous consumers.

Researching the manufacturer’s history and experience in the industry can help gauge reliability. Established manufacturers may have refined their production processes, leading to higher-quality outputs compared to newer or lesser-known companies that might compromise on quality for lower costs. Organizations that invest in research and development are likely to produce advanced products, enhancing overall performance and longevity.

Additionally, assessing customer service and support provided by manufacturers is crucial. A company that values its customers will typically provide ample resources for helping users understand product specifications and troubleshooting issues. These factors foster trust and confidence, essential elements when considering a long-term investment in solar ball valves.

FREQUENTLY ASKED QUESTIONS

WHAT FACTORS SHOULD BE CONSIDERED WHEN CHOOSING A SOLAR BALL VALVE?

Selecting an appropriate solar ball valve necessitates careful examination of several critical factors. Material choices, such as stainless steel or brass, greatly affect both functionality and longevity. For instance, brass offers robustness and excellent corrosion resistance, making it a suitable choice for various climates. Conversely, PVC might prove advantageous in lightweight applications due to its low cost, but could struggle under higher pressures.

Manufacturer reputation is another significant consideration. A reputable manufacturer typically adheres to quality standards, ensuring that products pass rigorous testing. It is advisable to consult reviews and feedback from previous customers, as these can provide insights into real-world performance. Additionally, proper certifications guarantee compliance with industry norms, assuring customers of the valve’s reliability. Overall, a comprehensive evaluation of these aspects can lead to informed decision-making.

HOW CAN YOU ENSURE THE LONGEVITY OF SOLAR BALL VALVES?

Maintaining the longevity of solar ball valves hinges on appropriate installation, regular maintenance, and environmental conditions. Proper installation is paramount; it is crucial to follow manufacturer guidelines closely to prevent issues related to pressure or misalignment.

Additionally, regular maintenance checks can identify wear and tear before they evolve into significant problems. This routine may include inspecting seals, assessing for leaks, and cleaning valve components to prevent debris accumulation. The environmental conditions surrounding the valve installation also play a role in its longevity; exposure to extreme temperatures or corrosive substances can hasten deterioration. By acknowledging these factors, users can promote the extended service life of their solar ball valves.

WHAT ARE THE SIGNS OF A FAULTY SOLAR BALL VALVE?

Dismal performance and a variety of irregularities can indicate that a solar ball valve is malfunctioning. Common signs include leaking, which often points to worn seals or an improperly seated valve ball. Any visible water accumulation around the valve area should be addressed immediately, as this can exacerbate damage over time.

Another clear indicator is difficulty in operation. If the valve becomes excessively stiff or fails to turn smoothly, it may be indicative of internal damage or debris obstruction. In some cases, reduced flow rates could imply that the valve is not fully opening, signaling a potential malfunction. Addressing these symptoms promptly can help prevent further complications and ensure efficient operation.

FINAL THOUGHTS ON JUDGING SOLAR BALL VALVE QUALITY

In the quest for high-quality solar ball valves, consideration of several pivotal factors is essential for optimal performance and reliability. The influence of material composition, such as brass or stainless steel, is paramount, as it directly affects durability under varying conditions. A proper understanding of the composition aids in selecting suitable valves for differing applications, particularly those exposed to harsh environments or fluctuations in temperature.

Attention to certification cannot be overlooked either, as industry-standard approvals provide assurance of product safety and effectiveness. Seeking valves that comply with recognized guidelines can lead to the selection of products that not only meet technical requirements but also enhance safety for users and environments alike.

The design aspects of solar ball valves play a significant role in their functionality and ease of use. Consideration of components like the ball, seals, and overall body construction should guide purchasing decisions. Attention to these elements can prevent common issues such as leaks or diminished flow rates, ultimately extending the product’s lifespan.

Reputational factors tied to the manufacturers also warrant careful evaluation. Companies with a long-standing history of producing high-quality products are more likely to provide reliable solutions. Resources for customer support and technical assistance can further enhance the consumer experience, ensuring that any arising concerns are promptly addressed.

In sum, making informed choices in selecting solar ball valves can profoundly impact the longevity and efficiency of associated systems. By examining these components diligently, users can ensure that they select high-quality products that meet their specific demands while promoting effective performance and durability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-judge-the-quality-of-solar-ball-valve/