1. Installation of valves in solar energy systems is essential for maintaining flow control, ensuring safety, and optimizing the efficiency of the system. 2. Two primary types of valves commonly used are check valves and ball valves. 3. Check valves allow fluid flow in one direction, preventing backflow, while ball valves facilitate easy manual shutoff or regulation of flow. 4. Proper installation techniques, including correct orientation and ensuring tight sealing, are crucial for the effective operation of these components.

1. UNDERSTANDING THE ROLE OF VALVES IN SOLAR ENERGY SYSTEMS

Valves play a pivotal role in the functioning of solar energy systems, particularly in managing fluid dynamics within solar collectors and storage tanks. Understanding their function is paramount for anyone looking to optimize solar energy infrastructure. Primarily, valves control the flow of heat transfer fluids, which are essential for transferring captured solar energy from the collector to storage systems or directly to the point of use. By regulating these fluids, valves ensure that systems operate efficiently, and necessary adjustments can be made as per demand.

Moreover, valves contribute significantly to the system’s safety. In the event of a malfunction or unexpected pressure buildup, valves can prevent catastrophic failures by shutting off flow or allowing for venting. This aspect underlines the importance of choosing the right types of valves and ensuring proper installation, which are critical for the longevity and safety of solar energy systems.

2. TYPES OF VALVES USED IN SOLAR ENERGY SYSTEMS

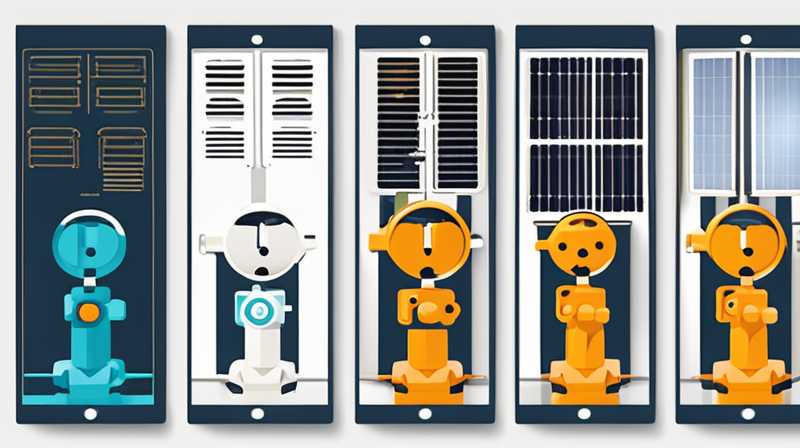

There are several types of valves utilized in solar energy systems, each designed for specific applications. The two most prevalent categories are check valves and ball valves, but other types—such as gate valves, globe valves, and pressure relief valves—also play important roles.

Check valves are designed to permit fluid to flow in one direction only, thus preventing backflow that could damage solar collectors or piping. They are vital in systems where a distinction between supply and return lines is necessary. Efficient operation of a solar thermal system hinges on the correct placement and functional integrity of these valves. For example, in a typical installation, a check valve should be placed close to the pumping unit to ensure that fluid does not revert into the collector when the pump is turned off.

Ball valves, on the other hand, allow for easy manual operation, providing a straightforward means of shutting off flow or adjusting it as needed. They are highly reliable and offer minimal resistance to flow when open, making them an integral component in both residential and commercial solar setups. Used typically on the supply line to tanks and collectors, their design permits rapid changes in flow direction without notable pressure drops.

3. PLANNING AND PREPARING FOR INSTALLATION

A successful valve installation in solar energy systems requires meticulous planning and a clear understanding of the specific requirements of the solar setup. Both the manufacturer’s guidelines and local plumbing codes must be reviewed thoroughly. Understanding the spatial dynamics and the overall layout of the solar installation will also aid in effectively positioning the valves.

Before beginning the installation, it is essential to gather all necessary tools and materials. Typically, these include the valves themselves, wrenches, sealants, and Teflon tape for sealing threaded connections. Ensuring that all components are compatible with the materials used in the piping system will prevent complications during installation and operation.

Furthermore, it is wise to prepare the installation site by ensuring that the area is clean and accessible. This preparation can significantly reduce the time needed during actual installation, helping to minimize disruptions to the overall project timeline. Engaging in careful planning at this stage can lead to a hassle-free installation experience.

4. STEPS FOR INSTALLING VALVES IN SOLAR ENERGY SYSTEMS

Installing valves in a solar energy system requires a systematic approach.

4.1. TURNING OFF THE SYSTEM

First and foremost, it is crucial to turn off the solar energy system to prevent any accidental fluid spillage or contamination during the installation process. This usually involves shutting off the pumps and allowing the fluid to drain from the pipes if necessary. Once the system is powered down and de-pressurized, it will also be easier to work with the piping systems.

4.2. REMOVING EXISTING FITTINGS

In many cases, valves will be installed as replacements for existing fittings, or new valves may require the installation of additional piping sections. If replacing an existing valve, care must be taken to remove it without damaging adjacent fittings or pipes. Often, cutting tools or pipe wrenches are necessary to adequately detach the old valve. Always ensure that the removal process does not lead to contamination of the solar fluid system.

4.3. POSITIONING THE NEW VALVE

Once the old valve has been removed, it is time to install the new valve in the correct orientation. Most valves have an arrow indicating the direction of flow, an important detail that must be adhered to for optimal operation. Failure to install the valve in the correct orientation may lead to inefficient operation, increased wear, or even system failure.

4.4. SECURING THE CONNECTIONS

The next step involves tightening the connections of the newly installed valve. Utilizing Teflon tape on threaded connections can enhance sealing and prevent leaks. It is essential to avoid over-tightening as it may damage the valve threads or the pipe. Each connection should be checked thoroughly for potential leaks, as any leaks can undermine system performance and safety significantly.

4.5. TESTING THE 시스템

After installing and securing the valve, it is imperative to test the entire system. Reaching out to a qualified technician may be a recommended course of action for anyone unfamiliar with solar energy systems. A successful test will confirm that the valve operates correctly, with no observable leaks. Careful monitoring of fluid flows should also be assessed to ensure that the valves function properly under various conditions.

5. REGULAR MAINTENANCE AND INSPECTION OF VALVES

Once valves are successfully installed in a solar energy system, proper ongoing maintenance becomes essential for sustaining their functionality. Regular inspections will help identify potential issues early on, leading to long-term reliability and efficiency of the solar energy system.

5.1. FREQUENCY OF INSPECTIONS

Establishing a routine for inspections should take into account the specific environmental conditions surrounding the solar installation. In areas subject to extreme weather changes or heavy debris accumulation, more frequent inspections may be warranted. Conversely, in controlled environments where external factors are minimized, inspections may be performed at longer intervals.

5.2. SIGNS OF WEAR AND TEAR

During each inspection, it’s important to look for visible signs of wear and tear, such as corrosion or leaks. Valves made from various materials will exhibit different susceptibility to degradation. For instance, brass and stainless steel valves are known for their resilience but are not immune to multifaceted wear factors. When issues are identified, timely repairs or replacements are warranted to maintain system integrity and efficiency.

6. COMMON CHALLENGES DURING INSTALLATION

Even with careful planning and execution, challenges may arise during the installation of valves in solar energy systems. Understanding potential pitfalls can aid in mitigating frustrations. Safety concerns, especially concerning pressurized systems, can provide setbacks if not managed diligently.

6.1. HANDLING PRESSURE DIFFERENTIALS

During installation, it is vital to properly address the pressure differentials within the system. Ignoring pressure fluctuations might lead to mishaps, resulting in personal injury or equipment damage. Properly balancing the various components involved will facilitate a smoother installation process. Knowledge regarding valve sizing and compatibility is crucial during these situations, as it informs the installer about potential adjustments.

6.2. WEATHER INFLUENCES

External factors such as temperature variations may cause expansions or contractions in pipe materials, adversely affecting valve functionality. Taking weather into account during installation can minimize the likelihood of these challenges arising. Utilizing proper construction materials will further support durability and efficiency.

FAQs

1. WHAT ARE THE BENEFITS OF INSTALLING VALVES IN A SOLAR ENERGY SYSTEM?

The installation of valves in a solar energy system offers numerous advantages. Primarily, valves facilitate the effective control of fluid flow, which is essential for maximizing the system’s efficiency. By managing the flow of heat transfer fluids, valves help to optimize the transfer of solar energy, ensuring that energy from solar collectors reaches storage systems or end-use applications effectively. This control also allows for isolating specific sections of the system for maintenance without requiring the shutdown of the entire system.

In addition to flow control, valves contribute to the safety of solar energy systems. By allowing for pressure relief and the prevention of backflow, these components guard against potential system failures. This is particularly essential in systems that experience pressure fluctuations or uneven heating characteristics. Moreover, regular inspections and maintenance of valves can prolong the lifespan of the entire solar energy infrastructure, thus yielding better returns on investment over time.

2. HOW OFTEN SHOULD VALVES IN SOLAR ENERGY SYSTEMS BE INSPECTED?

The frequency of valve inspections in solar energy systems can depend largely on various operational and environmental factors. In general, a routine inspection schedule should be established, ideally occurring at least once a year or as part of regular system maintenance. Areas characterized by harsh environmental conditions, such as extreme temperatures or the potential for debris accumulation, may necessitate more frequent inspections to ensure consistent performance.

During each inspection, it is vital to check for signs of wear, corrosion, or leakage. Addressing any issues promptly will prevent further complications that could lead to costly repairs. It is also essential to consult the manufacturer’s guidelines, as these will provide specific recommendations based on individual valve types and conditions. Ultimately, a proactive approach ensures the long-term integrity of the solar energy system.

3. CAN I INSTALL VALVES IN MY SOLAR ENERGY SYSTEM MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Whether to undertake valve installation in a solar energy system independently or to enlist the assistance of a qualified professional often depends on the individual’s technical proficiency and experience with plumbing systems. For those with substantial knowledge, performing the installation could save costs on labor. Essential aspects like proper valve selection, ensuring correct orientation, and maintaining tight seals are critical to system function and safety.

However, if an individual is unfamiliar with the intricacies of solar systems or plumbing, hiring a professional is advisable. Professionals bring expertise that can identify underlying challenges, recognize the appropriate valve types, and establish precise installation techniques. Ultimately, the decision should factor in not only one’s skills but also the complexity of the solar energy system in question.

Effective installation of valves in solar energy systems is crucial for maintaining the integrity, efficiency, and safety of the setup. Just as importantly, consistent maintenance ensures longevity and optimal performance. Understanding the different valves available, their specific functions, and adhering to professional standards during installation are paramount to maximizing benefits. Addressing each phase methodically, considering potential challenges, and implementing routine inspections contribute significantly to the smooth operation of solar energy systems. Engaging a trained technician can enhance the entire process, assuring adherence to best practices, ultimately leading to a reliable, long-lasting solar energy solution.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-valves-in-solar-energy/