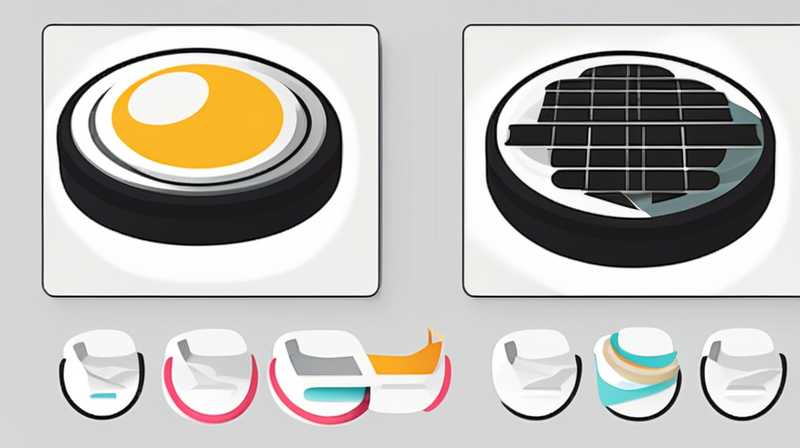

To successfully install the solar tube rubber ring, several steps must be followed to ensure an effective and watertight seal. 1. Proper preparation is essential, 2. Select the right rubber ring size, 3. Carefully fit the rubber ring, 4. Secure all connections and seals. In detail, preparing the installation site involves cleaning the area thoroughly to remove any debris or old seals. Choosing the appropriate size of the rubber ring is critical since an improper fit can lead to leaks or inefficiencies. When fitting the rubber ring, ensure it’s properly aligned and seated to facilitate maximum seal efficiency. Lastly, securing the connections guarantees the installation’s longevity and performance; the use of compatible fasteners and adhesives can enhance the durability of the installation.

1. PREPARATION OF THE INSTALLATION AREA

In the realm of solar technology, ensuring the effectiveness of any component begins with thorough preparation. Cleaning the installation area is paramount; debris or dirt can hinder the adhesion and effectiveness of the rubber ring. Tools and materials needed might include a clean cloth, mild detergent, and basic hand tools for local disturbances. After the area has been cleaned, assessing the condition of the existing parts is crucial. Any rust or degradation in the surrounding fittings could affect the longevity of the installation and the overall solar tube functionality.

Next, one must verify the compatibility of the rubber ring with the solar tube system. Checking specifications is critical; this involves measuring the diameter and thickness requirements for the rubber ring based on the manufacturer’s guidelines. If any discrepancies are found in size or compatibility, adjustments or replacement may be needed, which delays the installation process. Ultimately, a well-prepared installation area sets the foundation for effective solar tube performance.

2. CHOOSING THE RIGHT RUBBER RING

Selecting the correct rubber ring requires careful analysis of several factors. Understanding the components of your solar tube system is vital; not all systems utilize the same specifications, and variations between models necessitate precise selections. Consulting the manufacturer’s documentation can provide insights into the optimal size and type of rubber ring required.

Aside from size, scrutinizing the material is equally essential. Natural rubber, silicone, and EPDM (ethylene propylene diene monomer) are common choices; each material type possesses distinct attributes such as temperature resilience and UV resistance. For instance, while natural rubber offers flexibility, EPDM tends to perform better under fluctuations in temperature and exposure to sunlight. Evaluating the expected environmental conditions will assist in determining which material will yield maximum performance and longevity for the installation.

3. FITTING THE RUBBER RING

Once the correct rubber ring has been chosen, the next step is the fitting process. Proper alignment is crucial to ensuring a secure seal; misalignment can result in leaks or inefficient performance. Begin by gently stretching the rubber ring if necessary to accommodate any variances in size, ensuring that it retains its shape and elasticity.

After positioning the rubber ring, it is important to check for any kinks or twists, as these can impede its ability to create a watertight seal. Manipulating the rubber ring into place should be done with care; use appropriate tools, such as a soft mallet, to encourage it into the correct position without causing damage. Once in place, inspecting for consistent contact along the entire surface is necessary. Ensuring that the rubber ring sits flat means that it will have the best chance of maintaining an effective seal long-term.

4. SECURING CONNECTIONS AND SEALS

With the rubber ring properly fitted, the final stage involves securing all connections and seals to ensure optimal performance. Utilizing compatible fasteners plays a significant role; inadequate or incompatible fastening may lead to eventual failure of the installation. It is advisable to use materials that are either corrosion-resistant or specifically designed for use with solar equipment.

Moreover, applying an appropriate adhesive or sealant can significantly bolster the integrity of the installation. Selecting the right type of adhesive is essential; sealants that provide flexibility while maintaining a strong bond are preferable, as they accommodate any natural expansion or contraction due to temperature variations. Following the manufacturer’s guidelines for drying times and curing will promote the most effective attachment.

FAQS

WHAT IS A SOLAR TUBE RUBBER RING?

A solar tube rubber ring serves as a crucial component designed to create a hermetic seal between the solar tube and its surrounding materials. Its function is to prevent any potential leaks or air penetration that may diminish the system’s efficiency. Depending on the exposure to environmental factors, the rubber used can vary, impacting longevity and performance. Without a properly functioning rubber ring, the overall integrity of the solar tube system may be compromised, leading to potential energy losses.

HOW DO I KNOW IF MY RUBBER RING IS THE RIGHT SIZE?

To ascertain the correct size of your rubber ring, accurate measurements are paramount. Begin by measuring the diameter of the area where the rubber ring will be installed. Utilizing a caliper or a measuring tape ensures precision; discrepancies could lead to improper fitting. Additionally, consult the specs provided by the device’s manufacturer, as these documents can indicate the recommended rubber ring size and shape tailored for your solar tube configuration. Verifying these elements will help eliminate installation issues, ensuring optimal performance from the solar system.

WHAT TYPE OF ADHESIVE SHOULD I USE WHEN INSTALLING THE RUBBER RING?

The selection of adhesive is fundamental to ensuring a secure installation of the rubber ring. Opt for a high-quality, weather-resistant adhesive that is formulated specifically for use with rubber materials. Such adhesives should provide flexibility; this characteristic is vital due to the thermal expansion and contractions that may occur in outdoor environments. Reading the manufacturer’s instructions will provide you with details on application and drying times, which are equally important to guarantee a proper bond.

Successful installation of a solar tube rubber ring relies on a multitude of considerations addressing preparation, material choice, precise fitting, and securing connections. Meticulous attention to detail ensures the longevity, performance, and overall security of the installation. Beyond the installation itself, educating oneself about components and maintenance practices can significantly enhance system reliability. Investing time in research and preparation ultimately translates into a more efficient solar energy system capable of delivering benefits long into the future. The choices made during this process can greatly impact both energy efficiency and material durability, reinforcing the importance of each step.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-solar-tube-rubber-ring-2/