1. The process of installing a solar silicone ring involves several clear steps: 1. Gather necessary tools and materials, 2. Prepare the installation area adequately, 3. Utilize the appropriate silicone adhesive, 4. Follow the manufacturer’s instructions diligently for optimal performance.

Proper installation significantly enhances the efficiency of solar applications, contributing to better energy capture and longevity. Failing to execute the installation meticulously can lead to water pooling, which adversely affects the durability of the system. Thus, it is essential to adhere to the outlined steps to secure an effective and lasting installation.

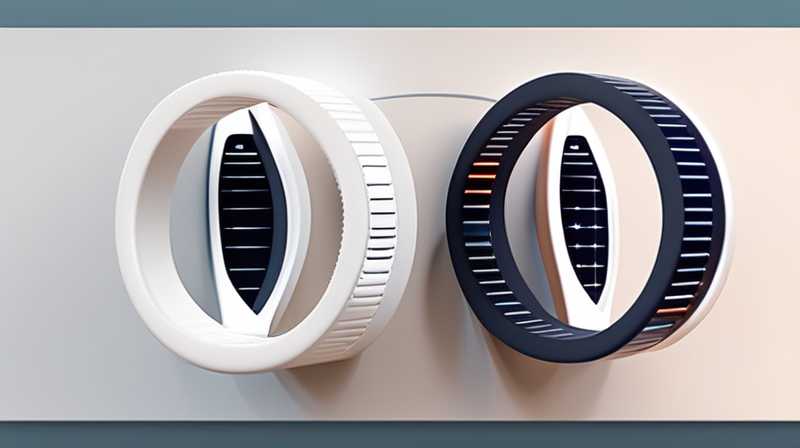

INSTALLATION PROCESS OF SOLAR SILICONE RINGS

TOOLS AND MATERIALS REQUIRED

Before initiating any installation endeavor, adequate preparation is vital for success. Identifying and gathering the necessary tools and materials sets the foundation for a smooth process. The primary components include silicone rings, a caulking gun, silicone adhesive, a utility knife, and a clean cloth.

A caulking gun is indispensable for dispensing silicone adhesive, ensuring even application. The quality of silicone adhesive selected is crucial, as not all products are designed for outdoor use. Opting for a silicone sealant specifically marketed for solar applications ensures longevity and resistance to environmental elements.

Thorough preparation can greatly impact the installation’s quality. Having all materials ready prevents unnecessary interruptions, allowing workers to maintain concentration on the task.

PREPARATION OF THE INSTALLATION AREA

Creating a suitable environment prior to installation cannot be overstated. Cleaning the area where the silicone ring will be installed is an essential step, as debris can weaken the bond. Use a clean cloth or sponge to remove any dust, dirt, or grime from the surface.

Utilizing isopropyl alcohol can ensure that any oils are eliminated, thereby enhancing adhesive quality. In certain cases, particularly with older surfaces, sanding may be beneficial to create a rougher texture for better adhesion. Achieving a proper surface ensures that the silicone sealant has the best chance to bond effectively.

Environmental conditions should also be taken into account. Ideally, installations should occur in mild weather conditions to maximize adhesive performance. Applying silicone in temperatures below 40°F can result in incomplete drying and ultimately lead to issues with water infiltration.

APPLICATION OF SILICONE ADHESIVE

Having set up the area, the next significant step involves the application of silicone adhesive. It is essential to carefully follow the manufacturer’s guidelines regarding application techniques. Begin by inserting the tube of silicone into the caulking gun and cutting the nozzle corner at a 45-degree angle.

When dispensing, maintain a steady hand to create an even bead along the edges of the surface where the silicone ring will be affixed. It’s advisable to apply a continuous bead to avoid gaps, which might become potential weak points for water infiltration.

Post-application, there is a crucial waiting period. Each type of silicone has a different curing time, which can affect the entire installation process significantly. Patience will prove beneficial here, as rushing this phase may lead to poor adhesion and potential failure of the installation.

INSTALLATION OF THE SOLAR SILICONE RING

With adhesive laid down, it’s time to move on to the installation of the silicone ring itself. Center the ring over the adhesive bead, ensuring it aligns perfectly with the desired position. Even pressure must be applied to ensure proper contact with the adhesive underneath.

Check for any trapped air bubbles during this process, as these can undermine the seal’s integrity. Using a flat tool can help to press out any trapped air and ensure good contact with the adhesive.

After achieving a proper seal, it’s important to consider the external elements. Securing the area with weights or clamps can provide additional protection against movement or misalignment while the adhesive cures. This additional precaution is particularly useful in windy conditions or when working outdoors.

CURING TIME AND FINAL INSPECTION

An often overlooked stage is allowing adequate curing time for the adhesive and silicone ring. Most silicone sealants require at least 24 hours to cure fully, and rushing this phase can have detrimental effects on the installation.

Once curing is complete, inspecting the entire installation is crucial. Examine the seal for continuity, ensuring there are no gaps or areas of concern. If any imperfections are noted, additional adhesive can be applied, or troubleshooting methods implemented to rectify the situation.

Conducting a proper inspection safeguards against future leaks and maintenance issues, thereby ensuring the longevity of the installation. Developing a scheduled maintenance routine is also advisable to address any potential wear and tear over time.

FAQs

WHAT ARE THE BENEFITS OF USING A SOLAR SILICONE RING?

Utilizing solar silicone rings provides several notable advantages. Firstly, these rings offer superior waterproofing capabilities, which are essential for moments of heavy rainfall or snow. The high-quality silicone material effectively prevents water intrusion, protecting the underlying structures of solar setups.

Furthermore, silicone rings exhibit excellent elasticity, allowing them to accommodate the movement and thermal expansion commonly experienced in outdoor settings, especially during different seasonal changes. This elasticity contributes to long-lasting performance and durability, preventing premature wear and extending the lifespan of solar elements.

Moreover, solar silicone rings are typically resistant to UV rays, meaning they won’t degrade quickly under sunlight. As solar energy systems are predominantly placed outdoors, ensuring that all components can withstand exposure to sunlight is imperative. This property also reduces the frequency of replacements, translating to cost savings in the long run.

HOW LONG DOES IT TAKE FOR THE SOLAR SILICONE TO CURE?

The curing time for solar silicone can vary depending on several factors, including humidity, temperature, and the specific product utilized. On average, most silicone sealants take between 24 to 48 hours to cure completely. Extreme temperatures may affect this time, with colder conditions typically requiring a longer curing period.

It’s essential to reference the manufacturer’s instructions for specific curing times, as this can differ slightly based on formulations. Maintaining stable temperature and humidity levels helps to facilitate proper curing, ensuring the adhesive reaches its optimal strength.

After the silicone has adequately cured, performing additional checks enhances water resistance and structural integrity. Some installers may choose to wait up to twice the standard curing time to ensure maximum adherence, especially if the installation is subject to extreme weather elements or high-pressure environments.

CAN THE SOLAR SILICONE RING BE REPLACED EASILY?

The replacement of a solar silicone ring can often be performed relatively easily, but it requires careful attention to detail. Initially, one should assess whether the current installation shows signs of significant wear or failure before proceeding with a replacement.

The first step in the removal process involves carefully cutting away the old silicone. Using tools like a utility knife ensures that the remaining surface is not damaged during this step. Once the old silicone is removed, thorough cleaning of the area becomes crucial for proper adhesion of the new ring.

After preparing the surface, follow the steps outlined for installation anew, ensuring to allow the necessary curing time for optimal effectiveness. Regular inspections of solar silicone rings post-installation can prolong their lifespan and indicate whether a replacement is needed promptly, thereby reducing complications in the future.

Executing a successful installation of solar silicone rings is pivotal for ensuring the efficiency and longevity of solar energy systems. Proper preparation, application, and inspection contribute significantly to the overall performance of these components. Armed with the aforementioned strategies, individuals can take proactive measures to install their solar silicone ring effectively. Engaging in routine maintenance further extends the functionality of solar setups over time. Cultivating an understanding of the necessary tools, integrating best practices during installation, and grasping the significance of environmental factors can prevent common pitfalls. While the installation process might initially appear daunting, adherence to the basic guidelines can facilitate a smooth experience. Investing time in diligent installation practices ultimately pays dividends in the form of enhanced durability, superior energy capture, and reduced repair needs in the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-solar-silicone-ring/