1. The process of installing a sealing ring on a solar tube involves several critical steps: 1) Ensure compatibility and gather necessary tools, 2) Properly prepare the installation site, 3) Position the sealing ring accurately, and 4) Secure the ring effectively. It is essential to consider the quality of materials and correct installation techniques to guarantee optimal performance and longevity of the solar tube system. Proper alignment ensures that the sealing ring maintains a tight fit, preventing any leakage that could impact functionality.

2. INSTALLATION PREPARATION

Prior to executing the installation of the sealing ring for a solar tube, it is imperative to conduct thorough preparation. First, one should ascertain the compatibility of the sealing ring with the specific solar tube model. Different manufacturers may produce distinct designs; hence, utilizing the appropriate sealing material is vital. Gathering tools such as a wrench, screwdriver, and any specialized equipment like a torque wrench will facilitate a smoother installation. Checking the manufacturer’s guidelines for specific requirements and recommended tools can prevent future complications and enhance the likelihood of a secure fit.

In addition to tool preparation, assessing the installation site plays a crucial role in the process. Ensuring that the area is clean and free from debris ensures that the sealing ring can fit seamlessly without obstruction. Light cleaning with appropriate solutions can eliminate any contaminants that may impair the sealing process. Moreover, examining the existing fittings for any signs of wear or damage is prudent; replacing compromised components before introducing a new sealing ring is wise, as doing so can support the overall integrity of the solar tube installation.

3. INSTALLING THE SEALING RING

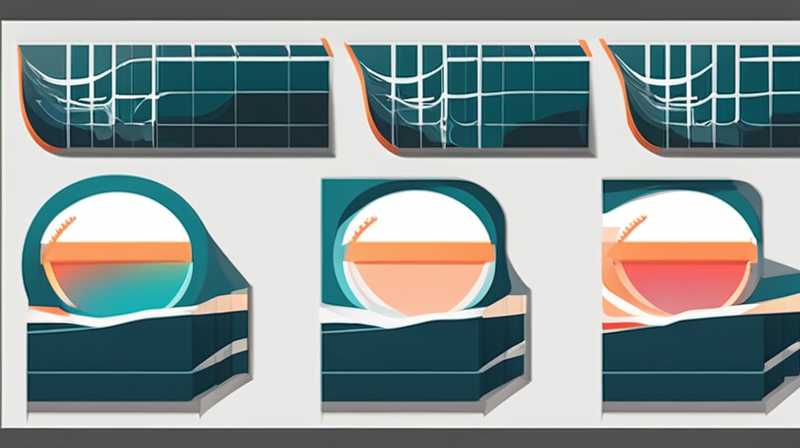

Once preparation is complete, the next logical step involves the actual installation of the sealing ring. Begin by positioning the ring into the corresponding groove of the solar tube. An important aspect at this stage is to ensure that the ring is correctly aligned. Misalignment can lead to gaps, reducing the efficiency of the solar tube by allowing air or water to seep through. This may compromise the entire installation and necessitate further work to fix potential leaks. Optimal methods include using your fingers to press the sealing ring lightly into place before applying more significant force with specific tools, ensuring that attention to detail is maintained.

After effectively positioning the sealing ring, the next task is to secure it. Employ the appropriate tools, taking care to follow any torque specifications outlined in the manufacturer’s guidelines. Over-tightening can lead to deformities in the sealing material, which may ultimately hinder its effectiveness. Conversely, if the ring is under-tightened, the integrity of the installation may be compromised, resulting in potential leaks. A step-by-step tightening pattern often assists in achieving an even application of pressure, minimizing the risk of uneven fitting.

4. TESTING AND MAINTENANCE

Following the installation, conducting thorough tests is essential to ensure proper functionality. Start by examining the sealing area visually to check for any visible flaws or misalignments. It is advisable to perform pressure tests using specific tools designed for checking seal integrity. Should any discrepancies arise during these tests, further adjustments may be necessary. Finding and resolving any issues before fully integrating the solar tube system is prudent, as this can prevent more significant problems in the future.

In addition to testing, performing regular maintenance on the installation is critical to its longevity. Regular checks of the sealing ring and surrounding components can help identify any signs of wear or degradation over time. Environmental factors, such as extreme weather conditions, can impact the performance of sealing materials—therefore, keeping an eye on the condition of the installation in various seasons is wise. Scheduling seasonal inspections and proper maintenance aids in sustaining the efficiency and functionality of the solar tube system, ensuring that it operates at optimal levels.

5. FAQ SECTION

WHAT KIND OF TOOLS DO I NEED TO INSTALL A SEALING RING ON A SOLAR TUBE?

To install a sealing ring on a solar tube, specific tools are essential in ensuring a successful installation. Primarily, a wrench or socket set is required to tighten fittings securely and is crucial in applying the appropriate torque. A screwdriver, especially a Phillips head type, may also be necessary for loosening or securing screws that hold various components in place. In more complex installations, a torque wrench provides a precise measure of torque when securing fittings, which is paramount in avoiding the common pitfalls of over-tightening or under-tightening the sealing ring. Having a piper cutter at hand can help with trimming excess materials if needed. For safety and efficiency, it’s advisable to refer to the manufacturer’s recommendations regarding specific tools tailored to the model of the solar tube in use. Ensuring the availability of all necessary tools before beginning the installation will significantly enhance the likelihood of success and reduce frustration during the process.

HOW CAN I ENSURE THE SEALING RING IS INSTALLED PROPERLY?

Proper installation of the sealing ring is crucial for ensuring that the solar tube functions efficiently. To ensure a correct fit, start by ensuring the cleaning of the installation site where the ring will be placed. Debris or dirt can prevent a secure fit, leading to potential leaks. Align the sealing ring accurately within its designated groove, employing gentle pressure to avoid any misalignments. Following this, it’s important to secure the ring using the tools specified in the installation guidelines, taking special care to respect the required torque specifications. Aging or damage to original components should be replaced prior to installation, as this can impact the sealing process’s integrity. After installation, conducting pressure tests can verify the ring’s effectiveness. Regular maintenance checks are also advisable, as they can identify any adjustments needed over time to maintain efficiency.

WHAT SHOULD I DO IF I DETECT A LEAK AFTER INSTALLATION?

Detecting a leak post-installation of a sealing ring on a solar tube can be concerning, but several steps can be taken to address the issue promptly and effectively. Initially, the problem needs immediate assessment; identify the leak source by checking visible areas around the sealing ring for signs of moisture or water seepage. It may be necessary to dismantle parts of the installation to examine the ring and surrounding components more thoroughly. Ensuring that the sealing ring itself is properly fitted and undamaged is vital; if any deformities or misalignments are identified, adjustments must be made accordingly. In some cases, the sealing ring may need to be entirely replaced if the material shows signs of deterioration or fatigue. Once repairs or adjustments are completed, conducting rigorous pressure tests is essential to verify that the leak is resolved and the solar tube is functioning optimally. Implementing regular maintenance checks after resolution will help prevent future complications and promote long-lasting performance.

6. INVITE TO ACTION

Installation of a sealing ring on a solar tube is a detailed process that requires careful consideration and execution. Thorough preparation, correct alignment, appropriate tool usage, and routine maintenance play pivotal roles in achieving a successful installation and optimal functionality. Investing time in understanding the components involved, ensuring compatibility, and following manufacturer guidelines enhances the durability and efficiency of the solar tube system. Not only does proper installation prevent leaks and issues, but it also secures the long-term performance of solar energy systems, fulfilling energy production goals. Should any challenges arise during installation, reaching out to professionals for support can further solidify the integrity of the system ensuring it meets the demands of renewable energy usage. To maintain operational effectiveness in the long run, establishing a routine inspection schedule and being cognizant of environmental conditions surrounding the installation can mitigate risks associated with malfunctioning components. The longevity and efficiency of your solar tube system hinge on a properly installed sealing ring, underscoring the importance of attentiveness to detail at every installation stage.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-sealing-ring-of-solar-tube/