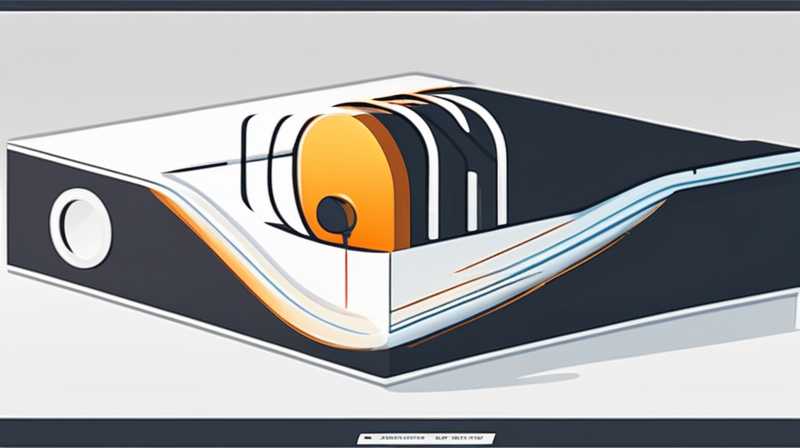

To properly install the sealing ring inside a solar tank, one must follow a systematic approach to ensure effectiveness and longevity of the system. 1. Identify the correct size and type of sealing ring suitable for your solar tank, 2. Gather all necessary tools and materials prior to starting the installation, 3. Follow safety protocols during installation to prevent accidents, 4. Carefully position the sealing ring to guarantee a tight fit within the designated area. The installation process requires attention to detail, as failure to properly secure the sealing ring could lead to leaks and inefficiencies in the solar heating system. Ensuring a perfect fit not only enhances the system’s performance but also prolongs its lifespan.

1. PREPARATION PHASE

Before diving into the actual installation of the sealing ring, meticulous preparation is key. This step involves gathering all necessary tools and materials needed for the procedure. Commonly used tools include a screwdriver, a pair of pliers, and a dedicated gasket or sealing ring tool. Having the right equipment at hand can significantly reduce the chances of errors during installation.

Furthermore, it is essential to identify the precise brand and model of the solar tank you have. Every manufacturer may have specific dimensions and types of sealing rings that fit their tanks. Referencing the user manual or contacting the manufacturer is advisable. By acquiring the correct information, one can prevent any mishaps that arise from using incompatible components.

Another important aspect of preparation is ensuring that the workspace is clean and free of distractions. A cluttered environment can lead to losing track of tools or misplacing the sealing ring, which could result in delays. Having a designated area for all components and tools will streamline the process, contributing to a more efficient installation.

2. SAFETY PROTOCOLS

When working with solar tanks, safety protocols cannot be overlooked. Conduct a thorough assessment of the site before beginning the installation. Check for any potential hazards such as electrical connections or nearby water sources. If the solar tank has been in operation, allow it to cool before starting the work to prevent burns or other injuries.

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves to protect the hands from sharp edges and safety goggles to shield the eyes from potential debris. Being aware of one’s surroundings during the installation is crucial. If assistance is available, securing a partner to help can make installation easier and safer.

It is also important to disconnect any power sources to the solar tank before proceeding. This measure will not only safeguard against electrical shocks but also enhance overall safety. Following these protocols not only protects the individual, but ensures the long-term integrity of the solar storage system.

3. REMOVING THE OLD SEALING RING

Upon making safety arrangements, the next step involves the removal of the old sealing ring. Inspect the existing ring for any signs of wear or damage. Removing the old sealing ring is often more challenging than anticipated. Careful handling of the solar tank and the surrounding components is necessary to avoid any unintended damage.

A flathead screwdriver can be employed to pry away the old sealing ring gently. Begin at one end and work your way around to ensure that the ring detaches evenly. This method will minimize the risk of damaging the tank’s edge where the sealing ring fits. If excessive force is required, it is a sign that further finesse is needed.

Once the old ring is successfully removed, it is critical to clean the groove where the sealing ring fits. Accumulated debris, dust, and residue can compromise the effectiveness of the new sealing ring. Using a cloth and mild cleaner, thoroughly wipe down the area to achieve a clean surface. A well-prepped surface is vital for the effective sealing of the new ring.

4. INSTALLATION OF THE NEW SEALING RING

With the old sealing ring removed and the surface cleaned, the focus shifts to properly installing the new sealing ring. Before starting, it is imperative to carefully inspect the new sealing ring for defects such as tears or irregularities. Ensure that the ring matches the specifications outlined in the product manual; otherwise, it risks being ineffective.

The installation of the new sealing ring demands precision. Begin by positioning the ring in the groove, ensuring that it is evenly distributed around the circumference. Alignment is vital; an improperly seated sealing ring can lead to leaks that compromise the tank’s efficiency.

Gently press the sealing ring into place, ensuring that it sits firmly within the groove. Avoid over-tightening or forcing the ring into position, as this can result in deformation or damage. Once positioned, check the entire circumference for evenness. Any inconsistencies should be adjusted at this stage.

5. VERIFYING INTEGRITY

Once the new sealing ring is installed, the next necessary step is to verify its integrity. This involves conducting a thorough inspection of the installation to affirm that there are no gaps or misalignments. A visual inspection is essential; one should ensure that the ring provides a uniform fit around the entire perimeter.

Following the visual inspection, it’s advisable to perform a pressure test. This step entails filling the solar tank with water and checking for leaks. If any leaks are discovered, immediate attention is required, as delaying repairs could lead to costly damages.

After a sufficient pressure test, it is crucial to monitor the system over a few days to ensure everything is functioning optimally. Any strange noises or signs of malfunction should be addressed promptly, ensuring that the installation is successful and the solar tank is ready for operation.

6. MAINTENANCE TIPS

Once the sealing ring is installed and the system verified, proper maintenance practices must be followed to ensure longevity. Regular inspections of the sealing ring are advisable to catch any wear and tear early on. During these inspections, look for signs such as cracking, discoloration, or loosening of the ring.

Moreover, maintain cleanliness around the solar tank. Environmental factors such as dust or debris accumulation can impact the efficiency of the sealing ring. Simple maintenance, such as wiping down the area periodically, can prevent long-term issues.

It’s also beneficial to familiarize oneself with the solar tank’s user manual for any specific maintenance routines or care instructions recommended by the manufacturer. Following these best practices will help extend the lifespan of the sealing ring and prevent costly repairs.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF SEALING RING SHOULD I USE?

Choosing the right sealing ring is essential for the performance of your solar tank. It is imperative to refer to the manufacturer’s specifications to find out which type fits your particular model. The sealing ring should match the tank’s diameter and material type, typically made from rubber or silicone. Using an inappropriate sealing ring can result in inefficiencies such as leaks or thermal loss. Always validate the product information either through the installation manual or by contacting the supplier directly.

HOW DO I KNOW IF MY SEALING RING IS DAMAGED?

Observing signs of damage in a sealing ring is crucial for the overall efficiency of a solar tank. Irregularities such as cracks, warping, or discoloration are clear indicators of wear. Conducting routine inspections, especially after significant temperature changes or after a season of heavy use, can help reveal these issues. If you notice leaks or an unusual drop in system performance, it may also indicate that the sealing ring is compromised. Immediate replacement of a damaged sealing ring is vital to restore the solar tank’s functionality.

CAN I REUSE A SEALING RING?

While it may be tempting to reuse a sealing ring, it is generally not advisable. Overtime, sealing rings can degrade due to temperature fluctuations and exposure to various elements. These changes may not be readily visible. Reusing an old sealing ring increases the risk of leaks or inefficiencies in the solar system. Although some materials may have longer lifespans than others, always err on the side of caution by replacing the ring during any maintenance procedure.

In summary, the installation of a sealing ring inside a solar tank requires meticulous attention to detail, adherence to safety protocols, and the right tools. Starting with proper preparation and ending with the implementation of maintenance routines ensures both a successful installation and long-lasting efficiency of the solar heating system. Following the outlined steps guarantees that the sealing ring fits snugly, eliminating potential issues that could arise from improper installation. Moreover, awareness of common pitfalls and remaining vigilant regarding maintenance will enhance the overall performance and longevity of the solar system, providing reliable heating for years to come. By embracing a proactive approach and understanding both installation and maintenance principles, anyone can effectively manage this task, ensuring optimal functionality of their solar energy system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-sealing-ring-inside-the-solar-tank/