To successfully install the inner skin of a solar tube, one must follow several essential steps that ensure both safety and efficiency. 1. Preparation is crucial, as having the right tools and materials guarantees a smoother installation process. 2. The design of the solar tube dictates specific methods for adhering the inner skin effectively. 3. Proper sealing techniques are necessary to enhance performance and prevent air leaks. 4. Regular maintenance post-installation is vital for longevity and functionality. Detailed explanation of preparation must consider the selection of suitable materials and personal safety gear to avoid any accidents during the installation procedure.

1. PREPARATION FOR INSTALLATION

When embarking on the installation of the inner skin of a solar tube, the initial phase requires meticulous preparation. Acquiring the appropriate tools and materials cannot be overstated, as this lays the groundwork for a successful outcome. Essential tools often include a utility knife, adhesive, a measuring tape, and a straight edge. It is also critical to gather all necessary materials, such as the inner skin itself, which typically comes in rolls, a high-quality adhesive that is suitable for the specific material being used, and, if applicable, any additional insulation or sealing materials.

Creating a clean and organized workspace can significantly enhance efficiency during the installation process. Clearing the area of debris and ensuring adequate lighting will not only facilitate better work conditions but also minimize the risk of accidents. Additionally, it is advisable to read through the manufacturer’s instructions thoroughly. Understanding each step outlined in the manual can prevent common mistakes and enable a more straightforward installation.

Moreover, taking careful measurements of the solar tube is integral. Accurate measurements help to determine the dimensions required for the inner skin and ensure a perfect fit. These steps foster a robust foundation, setting the stage for the subsequent phases of installing the inner skin.

2. SELECTING THE RIGHT MATERIALS

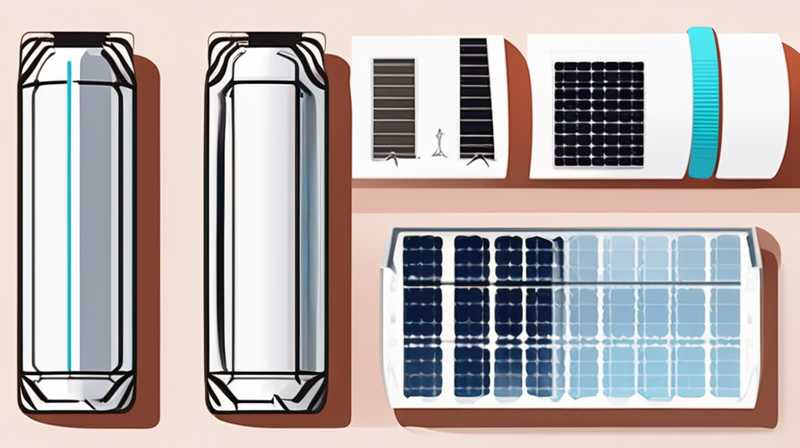

The choice of materials directly influences the efficiency and durability of the solar tube. The inner skin typically comprises reflective materials that optimize solar gain. Reflective surfaces, such as aluminum foil, provide exceptional light reflection, crucial for enhancing the overall effectiveness of solar tubes. An essential aspect of the installation process involves selecting materials that are specifically suited to the type of solar tube in use. This can include variations in thickness, textures, and reflectivity that cater to distinct energy needs.

In addition to selecting the right reflective inner skin, choosing an adhesive that meets the thermal requirements of the installation is vital. It is essential to select an adhesive that can withstand high temperatures and provide a durable bond between the inner skin and the tube. Be mindful that the adhesive should not detract from the reflective qualities of the inner skin, as this could lead to diminished performance.

Furthermore, considering the environmental implications of the materials chosen is imperative as well. Sustainable materials that minimize ecological footprints are increasingly relevant in today’s market. Selecting eco-friendly, non-toxic adhesives, for instance, aligns with broader sustainability goals and enhances the overall appeal of the installation.

3. INSTALLATION PROCEDURE

Once the groundwork in preparation and material selection is firmly established, the actual installation can commence. Begin by laying out the inner skin alongside the solar tube to get a clear idea of how each component fits. It is important to pay attention to the direction in which the reflective surface is facing, as this will influence efficiency. The reflective side must always face inward, towards the solar tube.

Next, cut the inner skin to the required dimensions, ensuring that the cuts are straight and clean for optimal adhesion. This is where the utility knife and straight edge play a key role. After cutting, dry-fit the pieces to ensure accuracy before applying any adhesive. It is often helpful to allow the adhesive to become tacky for a few moments before applying it to the inner skin. Applying the adhesive evenly throughout the surface can further enhance the bond and performance.

As you install, work your way along the solar tube carefully, pressing the inner skin into the adhesive to achieve a secure fit. One important aspect during this phase is to eliminate air bubbles and wrinkles. Utilizing a roller or a similar tool will assist in smoothing out the surface, preventing air leaks. This attention to detail in the sealing process is essential to maintain the efficiency of the solar tube.

4. SEALING AND FINISHING TOUCHES

The sealing process serves as a final step in solidifying the installation of the inner skin. Using weatherproof tape or additional adhesive can create a tight barrier against air leaks. Such measures are particularly crucial in ensuring longevity and efficiency, as they effectively minimize heat loss or gain. Care should be taken when applying sealant to maintain uniformity and prevent unnecessary mess.

Besides sealing, conducting a thorough inspection of the installation can uncover little details that may have been overlooked. Checking for gaps, lifting edges, or areas where the inner skin may not be properly adhered is essential. Rectifying these minor issues prior to finalizing the installation can significantly enhance the overall performance of the solar tube.

Furthermore, once the installation has been completed, implementing a regular maintenance schedule is advisable. Inspecting solar tubes at least annually can reveal any areas in need of touch-ups or repairs. This diligence will not only extend the life of the solar tube but will also ensure that it consistently performs at its best. Proper care and proactive maintenance practices are vital components of the longevity and efficacy of the entire solar setup.

5. MAINTENANCE AND LONG-TERM CARE

After installing the inner skin of a solar tube, understanding the importance of maintenance cannot be overstated. This period of time following installation offers an opportunity to ensure that the system operates correctly and efficiently. Routine checks can help identify potential issues before they develop into more significant problems. Such evaluations should focus on examining the integrity of the inner skin and any seals used during installation.

Regular cleaning of the solar tube is also critical. Dust and debris can obstruct the reflective surfaces, thereby reducing efficiency. Using a soft cloth to gently wipe down the inner surface can prevent this accumulation, allowing the solar tube to function optimally throughout its lifespan. It is recommended to use non-abrasive cleaning solutions to avoid damaging the reflective material.

In the event of noticing damage or wear on the inner skin, addressing these concerns promptly will help to maintain performance levels. Repairing or replacing compromised sections can significantly reduce potential efficiency losses. Periodic inspections and an understanding of the health of the solar tube’s interior will contribute to an extended service life and enhanced functionality.

QUESTIONS

WHAT TO CONSIDER WHEN SELECTING MATERIALS FOR THE INNER SKIN OF A SOLAR TUBE?

Choosing the correct materials for the inner skin of a solar tube is pivotal for achieving optimal performance. Reflective qualities play a substantial role; materials such as aluminum foil are highly effective, promoting increased solar gain. Durability is equally essential, as the inner skin should be able to withstand varying temperatures and environmental conditions without degradation. Furthermore, the adhesive selected must be compatible with both the inner skin and the solar tube itself, ensuring a strong bond that can last over time. Lastly, evaluating the environmental impact of materials chosen aligns with sustainable practices, which are increasingly important in today’s eco-conscious society.

HOW CAN I ENSURE MY INSTALLATION IS ENERGY-EFFICIENT?

To guarantee that your installation is energy-efficient, meticulous attention to detail when installing the inner skin of the solar tube is vital. Ensuring a tight seal and eliminating gaps is essential, as air leaks can severely diminish energy efficiency. Regular maintenance checks follow after installation; cleaning the reflective surfaces frequently and inspecting seals for wear and tear enhances the overall effectiveness of the solar tube. In addition, using high-quality reflective materials and adhesives designed for thermal applications reinforces energy-efficient performance. Understanding the principles of solar gain and adopting best practices in installation will ultimately lead to a more energy-efficient solar tube system.

WHAT MAINTENANCE IS REQUIRED FOR SOLAR TUBES?

Comprehensive maintenance of solar tubes involves several proactive measures. Firstly, routine inspections to assess the condition of the inner skin and seals can prevent small issues from escalating into significant problems. Cleaning the reflective surfaces regularly to remove dust and dirt is also crucial, as these can hinder light absorption and reduce efficiency. Checking the structural integrity of the solar tube aids in ensuring that it remains firmly installed and functions properly. Lastly, performing periodic evaluations of the entire solar system not only extends its lifespan but also enhances its overall effectiveness in energy collection.

The process of installing the inner skin of a solar tube is multifaceted and demands careful execution. Attention paid during the preparation phase sets the tone for all subsequent steps. Comprehending the importance of material selection, and the actual installation procedure, alongside ensuring proper sealing techniques, is crucial. Regular maintenance following installation cannot be neglected, as it plays a significant role in sustaining the solar tube’s efficiency and function. Moreover, a commitment to periodic inspections and care demonstrates a long-term investment in solar technology, yielding reliable energy solutions over time. Through diligent efforts and informed practices, solar tube installations can achieve optimal performance, reflecting a successful harmony between modern technology and environmental consciousness.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-inner-skin-of-solar-tube/