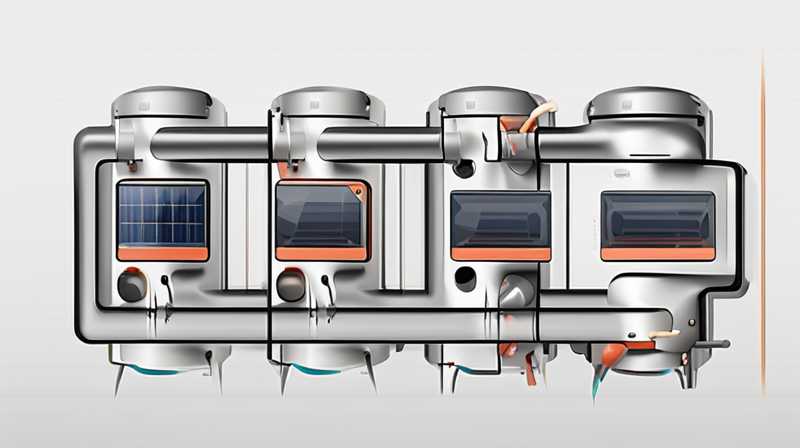

To install the exhaust valve of a solar manifold, one must follow a systematic approach that includes the essential components and the necessary steps to ensure proper functioning. 1. Understand the components involved, such as the solar manifold, exhaust valve, and associated piping, 2. Gather all required tools and materials, including wrenches, sealant, and safety equipment, 3. Prepare the installation site, ensuring it is clean and free from debris, 4. Follow a step-by-step process for installation, ensuring tight seals and proper alignment. The installation involves critical steps like turning off the system to prevent leaks and correct alignment of components to facilitate optimal performance. A careful and methodical execution assures the durability and efficacy of the solar heating system.

1. IMPORTANCE OF PROPER INSTALLATION

In the realm of solar energy systems, the significance of proper valve installation cannot be overstated. A solar manifold is a critical element that manages fluid distribution within the system, which is essential for efficient thermal performance. Proper installation of the exhaust valve ensures optimal pressure regulation, minimizes the risk of leaks, and maximizes energy efficiency. Additionally, it forms a crucial part of the safety mechanism, preventing overheating and ensuring that the system operates within its designed parameters.

Achieving the expected performance outputs hinges upon meticulous adherence to installation guidelines. When an exhaust valve is improperly installed, it can lead to various inefficiencies and potential system failures. For instance, one common issue resulting from faulty installation is the buildup of pressure, which can compromise the structural integrity of the manifold and associated pipes. Thus, taking the time to carefully follow installation procedures pays dividends in the form of long-term reliability and performance of the solar heating system.

2. TOOLS AND MATERIALS REQUIRED

Before embarking on the journey of valve installation, gathering all tools and materials is paramount. Essential tools include wrenches, screwdrivers, and pipe sealant, while the materials necessary encompass the exhaust valve itself, the solar manifold, and compatible piping. It is crucial to ensure that each tool is in good working condition and readily accessible to avoid interruptions during the installation process.

Additionally, investing in high-quality materials directly influences the durability and functionality of the solar heating system. Using inferior quality components can lead to increased maintenance costs and premature failures, leading to unnecessary downtime and potential repairs. Therefore, selecting the right materials ensures that the system will operate effectively for years to come. Furthermore, during the preparation phase, one should also consider safety equipment, including gloves and safety goggles, to prevent any injuries while handling tools and materials.

3. PREPARING THE INSTALLATION SITE

Preparing the installation site is a critical step that often gets overlooked. A clean and organized workspace is essential for ensuring a smooth installation process. This involves removing any debris in the vicinity and organizing tools and materials within arm’s reach. A clutter-free environment minimizes the likelihood of accidents and facilitates a more efficient workflow.

Moreover, it is necessary to check that the manifold is not under any stress or strain due to misalignment with neighboring components. Proper alignment is crucial for ensuring the longevity of the installation, as uneven forces can lead to wear and tear over time. Before commencing the installation, inspecting existing fittings and pipes is also advised to identify any potential issues that can be rectified beforehand, further promoting the integrity of the system upon final installation.

4. VALVE INSTALLATION STEPS

4.1 TURNING OFF THE SYSTEM

The first step in installing the exhaust valve involves ensuring that the solar heating system is completely powered down. This is crucial as it mitigates any risks associated with hot fluids or pressurized air that may be present in the system. It is advisable to consult the manufacturer’s guidelines to understand the specific shut-off procedures for the system in question. Once the system is turned off, the next step involves draining the solar manifold to relieve any pressure present.

Draining the system is a critical safety measure. It ensures that no hot liquid will cause burns during installation. Properly following this step allows for a smooth and safe installation, significantly reducing the chances of accidents during the procedure. Once the drain process is complete, it’s wise to inspect both the manifold and the existing valves for any wear or damage that could necessitate replacement or further attention.

4.2 REMOVING THE OLD VALVE

If there is a need to replace an existing valve, the next logical step is to remove the old valve from the manifold. To accomplish this, one should utilize a wrench to carefully unscrew the old valve, taking care not to apply excessive force that could compromise other components. After unscrewing, it is beneficial to have a container or towel nearby to catch any residual fluid that may escape during the removal process.

Once the old valve is detached, the next task is to thoroughly inspect the manifold for any residue or remaining sealant that may affect the integrity of the new installation. Cleaning these surfaces is essential, as any leftover material could interfere with the proper sealing of the new valve, leading to leaks or inefficiencies. Employing a non-corrosive cleaner is advisable to ensure that any gunk or sludge is effectively removed without causing damage to the manifold.

4.3 INSTALLING THE NEW VALVE

With the old valve out of the way, the installation of the new exhaust valve can commence. Begin by applying a thin layer of pipe sealant to the threads of the new valve to ensure a tight fit. It’s fundamental to ensure that the sealant is compatible with the existing system and materials to prevent degradation over time. The sealant provides an additional layer of security against leaks, which can significantly detract from the system’s performance.

Once the sealant is applied, the new valve can be threaded into place. It is important to hand-tighten the valve initially, ensuring alignment before using a wrench to secure it further. Care must be taken not to overtighten, as this can damage the threads or even crack the manifold. A snug fit is ideal, as it allows for the optimal operation of the valve while maintaining the integrity of the manifold assembly.

4.4 AIR RELEASE AND PRESSURE TESTING

With the valve successfully secured, the next critical phase involves releasing any trapped air from the system. This step is vital, particularly in solar systems where air can become trapped and lead to inefficiencies or even damage. To release air, one typically needs to open the air release valve, allowing for any stubborn air pockets to escape.

Following the air release, it’s prudent to conduct a pressure test to ensure that the valve and manifold are functioning properly. This can be achieved by slowly reintroducing pressure back into the system and monitoring for any leaks around the newly installed valve. Employing a systematic approach to observing any signs of leakage provides assurance that the installation was executed correctly and allows for immediate attention should any issues arise.

5. LONG-TERM MAINTENANCE PRACTICES

5.1 REGULAR INSPECTIONS

The installation process forms the foundation of a reliable solar heating system, but ongoing maintenance is equally essential. Regular inspections play a pivotal role in identifying potential problems before they escalate into significant issues. Setting a timetable for routine checks ensures that components, including the exhaust valve, are functioning as intended.

During inspections, looking for any signs of leaks, corrosion, or unusual sounds from the system can provide valuable insights into its operational state. Taking note of any irregularities allows for prompt action, ensuring the longevity of the entire system. Maintaining records of these inspections can help track the performance over time and identify any patterns that may emerge.

5.2 CLEANING AND RESEALING

As part of an integral maintenance regime, cleaning and resealing the valve connections periodically can extend the lifespan of the installation. Dust, dirt, and other debris can accumulate over time, possibly affecting the efficiency of the valve. A simple cleaning process using a soft brush helps keep the area clear, ensuring unobstructed operations.

Additionally, examining the sealant used during installation is prudent. Over the years, certain sealants may degrade due to exposure to extreme temperatures and weather conditions. Resealing may be necessary to maintain the integrity of the connections and prevent leaks, thereby safeguarding the operational capacity of the solar manifold system.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I CHECK THE EXHAUST VALVE?

Regular checks on the exhaust valve are critical for optimal performance in a solar heating system. Experts recommend conducting inspections at least twice a year, ideally in the spring and fall, to ensure that the valve is functioning correctly. Although this is an adequate timeline, there are specific conditions that may necessitate more frequent inspections. For instance, if your system has been subjected to extreme weather conditions, or if there have been noticeable fluctuations in performance, inspecting the valve promptly can help identify potential issues.

During inspections, one should look for any visible signs of wear or damage, paying particular attention to the areas including the sealing surfaces and connections. Any sign of leaks, discoloration, or corrosion warrants immediate examination and action. Creating a proactive maintenance schedule helps mitigate the risks of prolonged inefficiencies and potential damages. Thus, being vigilant of your solar system’s components, including the exhaust valve, significantly contributes to its longevity and performance.

WHAT SIGNS INDICATE A FAULTY VALVE?

Identifying a faulty exhaust valve early can prevent extensive damage to the solar heating system and improve overall efficiency. Several indicators signal a malfunctioning exhaust valve. Unusual sounds such as hissing or bubbling noises, inconsistent temperature readings, and visible leaks represent some common warning signs. A sudden spike in the energy bills may also indicate that the valve is not functioning correctly, leading to inefficiencies in heat distribution.

Furthermore, in terms of performance, if the system struggles to maintain pressure or does not heat up as efficiently as it once did, these could be manifestations of valve issues. Once such symptoms are recognized, it is vital to inspect the valve for any visible signs of damage or wear. If the issue persists, consulting a qualified technician or undertaking immediate repairs can help mitigate damage to the overall system.

CAN I INSTALL THE VALVE MYSELF?

Undertaking the installation of an exhaust valve offers a significant opportunity for hands-on engagement and learning about your solar heating system. However, whether one should proceed with a self-installation largely depends on individual capability and comfort with plumbing or mechanical work. If you possess sufficient skills and understand the intricacies of the installation process, you may effectively handle it on your own. Additionally, the availability of user manuals and instructional videos can provide substantial guidance during installation.

Nonetheless, if there is any uncertainty regarding the procedure or if specialized tools are required, engaging a professional is advisable. Expert installation ensures compliance with safety standards and industry regulations, reducing the likelihood of future problems. Overall, weighing personal ability against potential risks is key to determining whether to proceed with self-installation or seek professional assistance.

In summary, the installation of the exhaust valve in a solar manifold is a technical yet rewarding task that requires careful consideration and execution. Exploring the various aspects—from understanding the importance of proper installation to performing maintenance—can illuminate the pathway to achieving optimal system performance. One must not overlook the value of utilizing quality materials and adhering to best practices throughout the process. Moreover, proactive maintenance routines, including regular inspections and cleanings, can significantly enhance the longevity and efficiency of the entire solar heating system. Ultimately, thorough preparation and adherence to guidelines inevitably create a robust and reliable solar energy solution.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-the-exhaust-valve-of-solar-manifold/