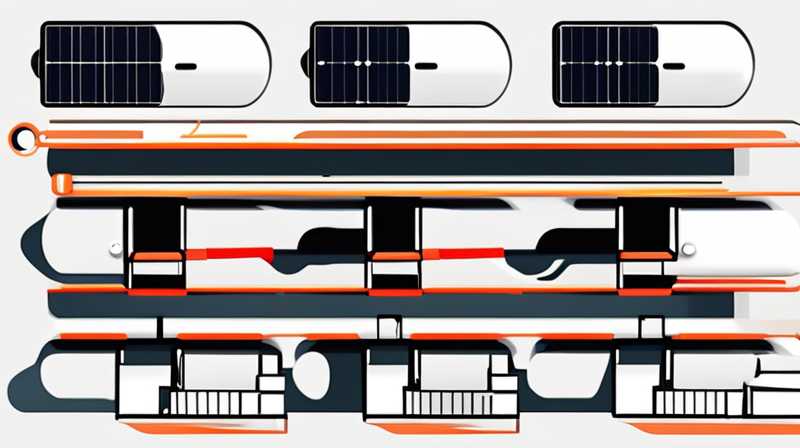

To install a solar valve core effectively, one must follow specific procedures that ensure optimal functionality and longevity. 1. Begin by gathering necessary tools, including a valve core tool and replacement cores, which are vital for the installation process. 2.Ensure that the system is depressurized before beginning, as working on a pressurized system poses safety risks. 3. Remove the existing valve core gently with the valve core tool, thus preventing any potential damage to the valve seat. 4. After removing the old core, examine the valve seat for debris or damage, making sure it is clean before installing the new core. 5. Insert the new valve core carefully, ensuring it is tight but not over-tightened to avoid stripping the threads, which can cause leaks.

The process requires precision and care to maintain the integrity of the solar system.

TOOLS REQUIRED FOR INSTALLATION

Initiating any installation requires a well-prepared set of tools tailored for the job. In this instance, having the correct tools serves a dual purpose: ensuring a seamless installation process and safeguarding the solar valve from potential damage. One essential tool is the valve core tool, specifically designed for the removal and installation of valve cores without exerting undue force on the surrounding components. Acquiring a high-quality valve core tool minimizes the risk of strippage and ensures proper torque specifications.

In addition to the valve core tool, one might also consider having a set of pliers, wrenches, or even a torque wrench depending on the complexity of the installation process. Various valve cores come in different types, and having a range of replacement cores can facilitate quick changes when needed. It is advisable to choose replacement cores that are both reliable and designed to withstand fluctuations in temperature and pressure, common in solar systems.

Having a clear work area devoid of obstructions is also critical; this contributes to a more organized approach and minimizes the chances of misplacing tools or components during the installation phase.

SAFETY PRECAUTIONS

Safety cannot be emphasized enough when dealing with any kind of installation, particularly those that interact with pressurized systems like solar valves. Your first step should be to familiarize yourself with the system layout, identifying all valves, pressure sources, and potential hazards before commencing work. Failure to adhere to safety protocols not only jeopardizes the integrity of the solar valve system but could also pose serious risks to individuals carrying out the installation.

In preparation, it is of utmost importance to wear appropriate personal protective equipment (PPE), including safety glasses and gloves, particularly when working near pressurized components. This simple measure can provide significant protection against potential injuries resulting from sudden pressure release or unexpected component failure. Moreover, creating a safe work environment by ensuring good ventilation and adequate lighting aids in maintaining focus and reduces the likelihood of accidents.

Before proceeding with the installation, take a moment to depressurize the valve system thoroughly. This involves either using a specific depressurization valve or releasing pressure in a controlled manner. Understanding how to effectively release pressure will not only simplify the installation step but will also serve as a critical measure for ensuring personal safety.

REMOVING THE OLD VALVE CORE

Once the necessary tools have been gathered and safety precautions have been addressed, the next step involves the extraction of the existing valve core from the solar valve. This stage is pivotal, as improper removal could not only damage the valve itself but could also compromise the entire solar heating system. To begin, ensure that the valve is fully depressurized as previously mentioned. Utilizing the valve core tool, approach the existing core carefully.

Position the tool over the valve core, and apply gentle pressure while turning to unlock the core from its seated position. The aim is to loosen it without any abrupt movements that could cause the valve seat to become damaged or excessively worn. Once loosened, you can extract the core completely. During this time, remain vigilant for signs of corrosion or damage on the valve seat; failure to secure a clean and functional seat can lead to leaks or efficiency issues with the solar system.

After removing the core, it is wise to perform a visual and tactile inspection of the valve seat. If any debris is present, this must be removed to allow for a proper seal when the new valve core is installed. Failure to achieve a clean interface could result in inefficient system performance, manifesting as lower heat retention or even system malfunctions over time.

INSTALLING THE NEW VALVE CORE

With the old valve core extracted and the seat thoroughly cleaned, the next phase involves the careful installation of a new valve core. Selection of the right replacement core is crucial; compatibility with the existing system components should always be verified to ensure optimal operation. Once you have identified a suitable core, it’s time to insert it back into the valve seat.

Using the valve core tool again, position the new core into the valve. It is imperative to apply steady and even pressure as the core is inserted for the first couple of turns. This ensures that the core threads align properly with those in the valve seat, minimizing the risk of cross-threading, which can lead to leaks. As the core is tightened, it is important not to over-torque, as this could lead to stripping of the internal threads, ultimately requiring replacement of the entire valve assembly.

Once fully installed and secured, consider the immediate environment of the valve. It is not just about the core itself but also how it performs within the entire solar system. Following installation, testing the system under operating conditions is advisable to ensure there are no leaks and that the system is performing as expected.

Monitoring the performance of the newly installed valve core over the first few cycles will offer insight into its effectiveness. Many systems include pressure gauges, and observing these readings can provide crucial information about the success of the installation and the efficiency of heat transfer within the solar system. Incorporating routine maintenance checks moving forward will enhance the longevity of the valve and the entire solar heating unit.

MAINTAINING SOLAR VALVES

After the successful installation of a solar valve core, ongoing maintenance becomes a critical element for ensuring continued efficiency and functionality. A well-maintained solar valve serves not only to regulate the flow of heated liquids but enhances the overall performance of the solar heating system. Regular inspections should be scheduled, ideally on a biannual basis, to assess the condition of both the valve core and the valve as a whole.

During these maintenance checks, one should look for signs of wear, such as corrosion, leaks, or loose fittings. Using appropriate tools to tighten loose components can enhance the integrity of the valve, thus preventing potential failures during peak system usage. Additionally, monitoring for any blockages or buildup in the valve can help in avoiding larger issues that may require more extensive repairs down the line.

Recognizing the importance of fluid dynamics within a solar heating system also plays a role in maintenance activities. Over time, impurities in the fluid can affect the operation of the valve, leading to inefficiencies in energy transfer. Flushing the system at intervals will help remove contaminants while optimizing the overall performance and extending the lifespan of the valve assembly.

In essence, proper installation followed by consistent monitoring and maintenance will ensure that the solar valve functions correctly, thus preserving the efficiency of the solar heating system over time.

TROUBLESHOOTING COMMON ISSUES

Despite thorough installation procedures and ongoing maintenance efforts, issues can occasionally arise. Recognizing common symptoms can significantly streamline a troubleshooting process and guide users to effective solutions in a timely manner. One prevalent challenge is leaking around the valve core, which often indicates that the core may not be seated properly or that it has become damaged.

If leaks are found, the first step is to shut down the system and depressurize it once again. From there, revisiting the installation to ensure the valve core is tight and properly seated is essential. In addition, inspecting the surrounding valve seat for any nicks or damage can help diagnose the problem further; replacing the valve seat may be necessary to achieve a secure seal if significant damage is observed.

Another frequently encountered problem involves inefficiencies in heat transfer, which might manifest as cold spots or inconsistent temperature within the system. This can be due to blockages within the valve itself or the components connecting the valve to the solar collectors or storage tanks. Flushing the system as discussed earlier may alleviate these obstructions, ensuring smooth operation.

Lastly, regular checks for any signs of corrosion can also prevent larger malfunctions, as neglect in this area might lead to complete breakdowns. Keeping a log of all maintenance records and issues encountered can enhance future troubleshooting efforts, as patterns may emerge that inform further preventative strategies.

QUESTIONS FREQUENTLY ASKED

WHAT IS A SOLAR VALVE CORE?

A solar valve core is a small yet vital component within a solar heating system designed to manage the flow of heat transfer fluids. Specifically, it works to regulate entry and exit points of fluids, contributing to the overall efficiency of the system. This part often gets overlooked, yet a malfunctioning valve core can lead to both inefficiencies and safety hazards within the solar system. In simpler terms, it plays an integral role in ensuring the proper circulation of fluids which are essential for the optimal performance of solar heating systems. Addressing issues related to valve cores promptly will ultimately extend the lifespan of the entire system, leading to more effective energy use.

HOW OFTEN SHOULD I REPLACE MY VALVE CORE?

The frequency of replacing a valve core in a solar heating system can vary based on multiple factors, including system usage, environmental conditions, and the quality of components used. Generally, if equipped with quality materials, valve cores may last several years without replacement. However, periodic checks should become part of routine maintenance to ensure they are functioning well. Signs of degradation, such as rust or leaks, warrant immediate attention and possible replacement. Incorporating these checks into your maintenance schedule alongside scheduled flushing of the entire system can prevent unforeseen issues arising and help to guarantee optimal system performance.

CAN I INSTALL A VALVE CORE MYSELF?

Yes, an individual can indeed undertake the installation of a solar valve core independently, provided they have a solid understanding of basic plumbing principles and the specific requirements of their solar system. Prior to beginning the installation, it’s essential to familiarize yourself with the tools needed and the steps involved in the process. Ensure that all safety measures are adhered to, especially working in a depressurized environment. If there’s any doubt, enlisting the help of a professional can provide additional assurance that the installation process adheres to all safety regulations and operational standards.

The installation of a solar valve core is a straightforward yet crucial aspect that significantly influences the efficiency of the overall solar heating system. Emphasizing safety and quality is paramount, along with mastering proper techniques for installation and maintenance. By following the outlined procedures meticulously, achieving the best performance from the solar system is not only possible but also sustainable. This harmonious integration of components ensures that the solar system continues to operate effectively, ultimately supporting eco-friendly energy initiatives while catering to individual heating needs. Comprehensive knowledge about the function and care of the solar valve core not only enhances individual confidence but lays a solid foundation for successful energy management and conservation strategies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-valve-core/