1. Proper selection of materials is crucial, 2. Installation requires precise measurements, 3. Ensuring a tight fit prevents leaks, 4. Regular maintenance enhances longevity.

When aiming to install solar tube gaskets effectively, one must first understand that the choice of materials plays a pivotal role in achieving optimal performance. Selecting high-quality gaskets made from weather-resistant and durable substances can significantly impact the overall efficiency of the installation. Additionally, meticulous measurements during the installation process are paramount; even minor discrepancies can lead to inadequate sealing and potential leaks. Ensuring that the gaskets fit snugly within the tubular structure is essential. Furthermore, regular inspections and maintenance of the installation will contribute to its longevity and sustained efficiency, preventing costly repairs and replacements.

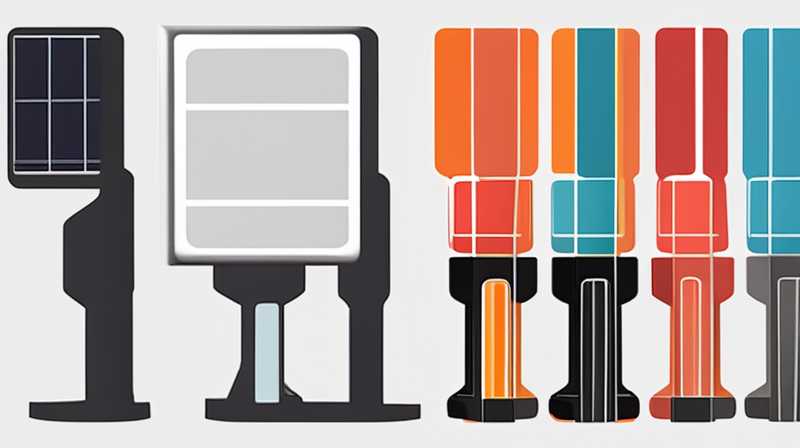

1. UNDERSTANDING SOLAR TUBE GASKETS

Solar tubes, often referred to as solar water heaters or solar collectors, capture solar energy and convert it into thermal energy for various applications such as heating water or air. The efficiency of these systems largely hinges on proper sealing, which is where gaskets come into play. Gaskets serve a critical purpose, acting as barriers to prevent air and water from infiltrating the insulated space within solar tubes. Understanding their design, materials, and functionality is essential for anyone looking to install these components successfully.

Gaskets, typically made from rubber, silicone, or neoprene, must withstand varying environmental conditions. Factors such as temperature fluctuations, UV exposure, and moisture levels can all affect a gasket’s integrity. Therefore, selecting a gasket with appropriate thermal and weather-resistant properties ensures long-lasting performance. Additionally, familiarity with the specific type of solar tube being used is imperative; this knowledge aids in determining the appropriate gasket dimensions and design needed for a precise fit.

2. SELECTING APPROPRIATE MATERIALS

When embarking on the installation process, the selection of materials is paramount. The longevity and effectiveness of solar tube gaskets depend heavily on the raw materials used in their construction. Some common materials for solar tube gaskets include EPDM rubber, silicone, and butyl rubber. Each type possesses unique characteristics tailored for specific environmental conditions.

EPDM rubber is particularly popular for outdoor applications due to its excellent resistance to UV radiation, ozone, and extreme temperatures. This material can endure a wide range of temperatures and has been proven effective in both hot and cold climates. Silicone gaskets, on the other hand, exhibit remarkable flexibility and resistance to high temperatures, making them ideal for areas where thermal fluctuation is common. Butyl rubber stands out for its adhesive properties, providing a strong seal that is resistant to moisture. Selecting the appropriate material based on environmental exposure and the specific application will enhance sealing performance and longevity.

3. MEASUREMENTS AND PREPARATIONS

One of the foundational aspects of a successful installation lies in accurate measurements. Proper measurements ensure that gaskets fit snugly, preventing gaps that could lead to air or water leakage. Before installation begins, the dimensions of the solar tube must be precisely determined. This often involves measuring the outer diameter of the tube, the inner diameter of the mounting frame, and the width of the surface area where the gasket will be seated.

Using tools such as calipers or measuring tapes will yield a precise fit, significantly reducing the likelihood of future issues. Beyond measurements, proper surface preparation is vital. The area where the gasket will be installed should be cleaned thoroughly to remove any dirt, dust, or old adhesive residues. This practice enhances adhesion and ensures a better seal, ultimately contributing to the effectiveness of the installation.

4. INSTALLATION TECHNIQUES

When installing solar tube gaskets, systematic techniques can ensure optimal results. A successful technique involves the careful placement of the gasket around the solar tube. Typically, the gasket should be unrolled and laid out flat before being cut to the required length. This process helps avoid any unnecessary stress on the material, which could lead to deterioration over time.

Once the gasket has been cut and laid out, it should be placed around the tube with a careful eye for alignment. Particular attention should be paid to ensure that the gasket is not twisted, as this can lead to incomplete sealing. After positioning the gasket, fastening it in place may involve appropriate adhesives or mechanical fastening methods. Following installation, it is essential to conduct a visual inspection and possibly a water test to check for any leaks.

5. ENSURING PROPER FIT AND SEALING

Once the installation has been completed, verifying the fit and sealing of the gaskets becomes crucial. A tight seal is essential for preventing airflow and water from infiltrating the solar tube. A visual assessment of the gasket’s placement will allow for the identification of any areas that might require adjustment. Any visible gaps or misalignments should be corrected immediately.

In certain cases, using a sealant in conjunction with the gasket can enhance the effectiveness of the installation. Sealants can fill in small gaps and bolster the overall sealing structure. However, it is important to select a sealant compatible with the material of the gasket to avoid material degradation over time. Additionally, a quality assurance check after installation will help ascertain that the gaskets fulfill their intended purpose in maintaining the efficiency of the solar tube system.

6. REGULAR MAINTENANCE PRACTICES

To promote the longevity of solar tube gaskets, establishing a robust maintenance routine is essential. Regular checks and maintenance can significantly extend the life of these essential components. Scheduling periodic inspections allows homeowners or operators to detect wear and tear before issues escalate into more significant problems.

Maintenance efforts should focus on assessing the condition of the gasket, checking for cracks, hardening, or any signs of wear due to environmental factors. Any visible damage should necessitate immediate replacement of the gasket to ensure efficient operation of the solar tube system. Keeping the surrounding area free of debris and dirt will also aid in maintaining the integrity of the seal, as accumulated materials can compromise the effectiveness of the gasket.

7. ENVIRONMENTAL CONSIDERATIONS

Incorporating environmental considerations into the installation and maintenance of solar tube gaskets is paramount. Material selection, durability, and disposal practices can impact sustainability efforts. Choosing gaskets manufactured from recycled or sustainable materials contributes to reducing the overall environmental footprint of solar tube systems.

Furthermore, ensuring proper disposal of old gaskets and materials can help mitigate pollution and waste. Engaging with suppliers who adhere to eco-friendly manufacturing practices can also enhance the sustainability of the installation. This holistic approach to environmental consideration not only benefits the immediate environment but also contributes to the global push for sustainable energy solutions.

8. COMMON ISSUES AND TROUBLESHOOTING

Understanding typical problems that may arise during the installation and use of solar tube gaskets is advantageous. Being proactive about troubleshooting can enhance the operational efficiency of the system. Common issues may include leaking, inadequate sealing, or deteriorating materials.

Identifying the source of a leak often involves examining the fit of the gasket and ensuring that it is properly seated. Checking for any surface damage and ensuring that the installation is free from contamination can also rectify these problems. Maintaining a troubleshooting log can help track recurring issues, guiding future maintenance and planning efforts for improved performance.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF GASKETS ARE BEST FOR SOLAR TUBES?

When selecting gaskets for solar tubes, materials such as EPDM rubber, silicone, and butyl rubber are often recommended due to their durability and resistance to various environmental factors. EPDM rubber is particularly effective for outdoor use, while silicone gaskets excel in high-temperature environments. Butyl rubber offers strong adhesive properties, making it an excellent choice where moisture resistance is critical. Each of these materials provides unique benefits tailored to specific applications, emphasizing the importance of assessing environmental conditions and expected temperature ranges before making a final decision.

HOW OFTEN SHOULD SOLAR TUBE GASKETS BE REPLACED?

The frequency of replacing solar tube gaskets varies based on several factors, including environmental exposure, material quality, and maintenance diligence. Typically, a thorough inspection should occur at least once a year, with immediate attention given to any visible wear or damage. If issues such as compromised seals, cracking, or significant discoloration occur, replacement is necessary. Proper maintenance practices can significantly extend the lifespan of gaskets; however, general guidance suggests that, on average, gaskets may need replacement every five to seven years. Monitoring performance and engaging in proactive maintenance allows for timely replacements that prevent larger system failures.

CAN I INSTALL SOLAR TUBE GASKETS MYSELF?

While many homeowners are capable of installing solar tube gaskets themselves, it is imperative to possess a good understanding of the process and required tools. Familiarity with appropriate materials, precise measuring techniques, and installation methods is crucial to ensure effectiveness. If one lacks experience or is unsure about certain steps in the process, it is advisable to consult with professionals to avoid incorrect installations, which could lead to inefficiencies or costly repairs down the line. Many manufacturers offer detailed instructions and guidelines, so leveraging these resources can empower individuals to confidently undertake the installation process.

The process to successfully install solar tube gaskets involves careful consideration and execution of multiple aspects. Each segment of the procedure, from selecting high-quality materials to conducting regular maintenance, plays a vital role in ensuring optimal performance and longevity of the solar tube system. The importance of proper installation cannot be overstated, as improper sealing can lead to considerable energy losses and potential damage. Adhering to best practices, including precise measurements, surface preparation, and routine checks, will enhance the operational efficiency of solar tubes while also contributing to overall sustainability. Engaging in proactive measures to prevent and address issues further solidifies a system’s reliability, making it crucial for users to remain diligent about maintenance and care. By embracing a comprehensive approach to all facets of the installation process, individuals can achieve a functional solar tube system that serves its intended purpose effectively and efficiently, ultimately reaping the rewards of renewable energy. The path towards energy independence and sustainability is paved with informed choices and dedicated efforts to preserve the integrity of those systems, fostering a better relationship with our environment.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-tube-gaskets/