1. INSTALLATION PROCESS FOR SOLAR TUBE CLAMPS 2. TOOLS AND MATERIALS NEEDED 3. SAFETY PRECAUTIONS 4. MAINTENANCE TIPS

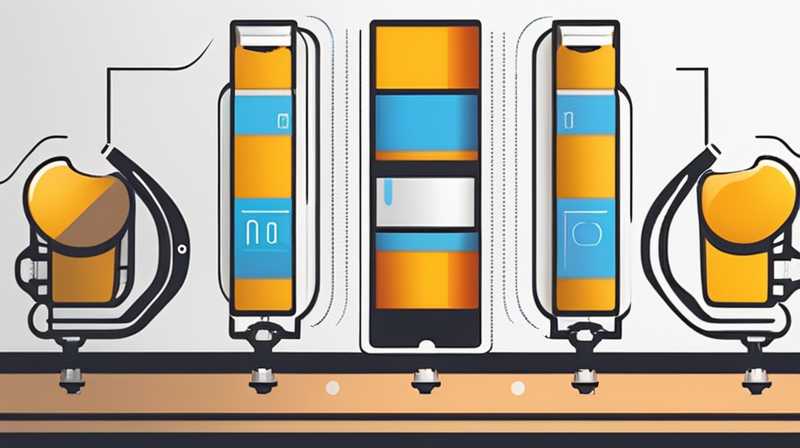

Solar tube clamps are essential components used to secure and stabilize solar tubes, enhancing both function and longevity. 1. Proper installation techniques are imperative regardless of the skill level of the installer, 2. Selecting the appropriate tools fosters efficiency and effectiveness, 3. Adhering to safety protocols ensures protection during the installation, 4. Regular inspections and maintenance prolong the lifespan of the installation. To elaborate, ensuring proper installation is critical as it not only affects the performance of the solar system but also minimizes potential damage from environmental factors such as wind or snow load. Unstable clamps can lead to misalignment of solar tubes, causing inefficiencies in energy capture and increased wear on materials over time. Understanding these points significantly impacts the long-term success of solar energy systems.

1. INSTALLATION PROCESS FOR SOLAR TUBE CLAMPS

The process of installing solar tube clamps necessitates precision and careful attention to detail. Initiating with a comprehensive assessment of the intended installation area is vital; this helps identify any obstacles and assures a correct fit for the solar tubes. Skipping this step can lead to significant complications during installation.

Next, it is crucial to position the solar tubes effectively. This means ensuring they are located at the ideal angle to maximize sun exposure throughout the day. Employing a protractor or an adjustable angle finder can facilitate this alignment. Furthermore, it is paramount to mark the spots where clamps will be mounted, allowing for accurate drilling and securing of the clamps.

Once the positioning has been established, the installation of the clamps can begin. Depending on the type of solar tube clamps chosen, they may require either screws or bolts for fastening. Pre-drilling holes is advisable as this can prevent cracks or splits in the mounting surface, especially if utilizing wood or composite materials.

2. TOOLS AND MATERIALS NEEDED

A variety of tools and materials are necessary for a successful installation of solar tube clamps. 1. Basic tools typically include a drill, screwdrivers, and wrenches, 2. Additional materials may comprise screws or bolts, clamps, a level, and safety gear.

The drill used should be of sufficient power to handle the material being fastened. For wood, a basic electric drill may suffice, but for metal, a more robust drill or specific metal drill bits might be needed. Alongside the drill, having a selection of screwdrivers can be beneficial as clamps may require different types of screws for secure attachment.

Safety gear is a must-have component during the installation process. Wearing goggles can protect the eyes from debris, while a hard hat can prevent injury from falling objects. Ensuring that all tools are inspected for proper function before usage helps maintain a smooth installation process.

3. SAFETY PRECAUTIONS

The necessity of safety precautions cannot be overstated during the installation of solar tube clamps. 1. Always utilize personal protective equipment such as goggles and gloves, 2. Inspect ladders and scaffolding for stability prior to climbing.

When working at heights, employing fall protection measures becomes essential. This may involve using harnesses or securing oneself with safety lines to prevent falls. Proper ladder etiquette, including maintaining three points of contact, ensures the installer’s safety while maneuvering on elevated surfaces.

Moreover, when utilizing power tools, it is crucial to familiarize oneself with their operation. Understanding how the drill and other tools function reduces the likelihood of accidents. Additionally, one should ensure that the work area is free from obstructions and clutter, which can lead to trips or falls while carrying tools and materials.

4. MAINTENANCE TIPS

Regular maintenance of solar tube clamps is essential to ensure their longevity and functionality. 1. Periodically inspect the clamps for signs of wear or corrosion, 2. Clean the solar tubes to maximize efficiency.

Routine inspections should be conducted at least twice annually or more frequently in areas prone to severe weather. During these inspections, look for loose clamps or corrosion that may indicate deterioration due to environmental exposure. Tightening any loose screws or bolts can help maintain stability, preventing future issues that may arise from unsecured solar tubes.

Cleaning the solar tubes is another critical aspect of maintenance, as dirt or debris can hinder solar energy absorption. Utilizing a soft cloth or specifically designed cleaning solutions can help maintain optimal performance. Additionally, avoiding abrasive materials ensures that the surface of the tubes remains undamaged.

FREQUENTLY ASKED QUESTIONS

WHAT ARE SOLAR TUBE CLAMPS?

Solar tube clamps are specialized fasteners designed to secure solar tubes to mounting frameworks. They play a crucial role in ensuring the stability and efficiency of solar energy systems. The clamps prevent movement of the tubes due to wind, snow, or seismic activity. By reducing the potential for misalignment, they help maintain optimal energy capture. Various types exist, each formulated for different installation surfaces or tube sizes. Choosing the right clamp type is vital for proper functioning, and they are available in several materials, including stainless steel and plastic, which offer varying degrees of durability and resistance to environmental conditions.

HOW DO I KNOW IF I’VE INSTALLED THE CLAMPS PROPERLY?

Verification of proper installation involves checking for several key indicators. First, the clamps should securely hold the solar tubes in place without noticeable movement. A visual inspection can be conducted by looking for any gaps between the clamps and the tubes, which may indicate improper sizing or installation. Additionally, when subjected to wind or other external forces, the clamps should maintain the tubes’ position. It can be helpful to monitor the equipment during adverse weather conditions initially to ensure they properly function. Any unexpected movement or noise indicates a potential issue that may need immediate attention.

WHAT MAINTENANCE IS REQUIRED FOR SOLAR TUBE CLAMPS?

Maintenance of solar tube clamps entails both visual inspections and cleanliness. It involves checking for signs of corrosion, loosening, or displacement. Regularly tighten any loose screws or bolts and ensure the integrity of the clamps. Cleaning the clamps and surrounding areas prevents dirt and grime buildup, which can obscure functionality. Scheduled inspections should happen after significant weather events or at the change of seasons to assess any damage that might affect performance. Additionally, any worn-out clamps should be replaced promptly to maintain system efficiency.

The emphasis on precision and planning in installing solar tube clamps cannot be underestimated. Proper installation ensures reliability, while using the right tools and adhering to safety measures protect the installer’s wellbeing. Furthermore, regular maintenance fosters longevity, which is critical in making the most out of solar energy systems. The comprehensive process involves various considerations, yet at its core, diligent attention to detail is what ultimately leads to successful installations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-tube-clamps/