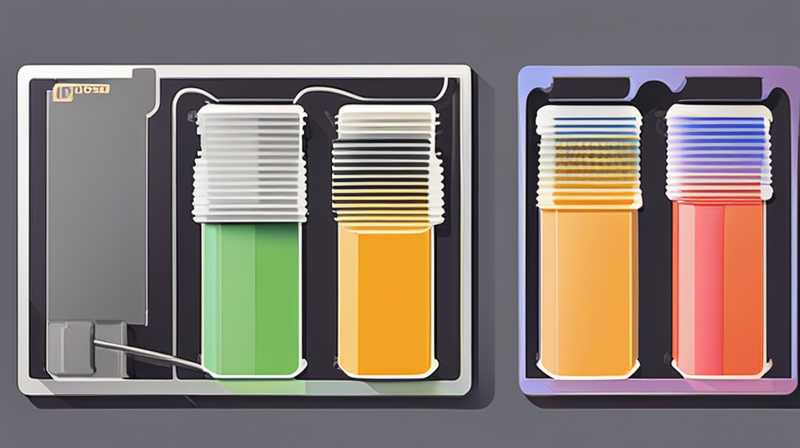

How to install solar thermal insulation rubber sleeve

To install a solar thermal insulation rubber sleeve, 1. gather essential tools and materials, 2. determine the correct length and size for the insulation, 3. prepare the surface for application, 4. position the sleeve carefully around the pipe, 5. secure it, ensuring a snug fit, 6. finish with tape or other sealant for durability, 7. inspect the installation for any gaps or loose areas. One crucial aspect is ensuring that the surface to which the rubber sleeve will be applied is clean and dry. This facilitates better adhesion and optimal thermal efficiency.

1. GATHERING ESSENTIAL TOOLS AND MATERIALS

Before embarking on the installation of solar thermal insulation rubber sleeves, properly gathering tools and materials is paramount for ensuring a smooth and effective installation process. The most common tools required include a utility knife, measuring tape, safety gloves, and scissors. Additionally, having materials at hand such as rubber sleeves specifically designed for thermal insulation, adhesive tape, or sealant will facilitate smoother workflow.

Choosing high-quality, durable insulation materials is essential. This ensures longevity and maximizes the effectiveness of the thermal insulation. Cheaper alternatives may lead to issues with heat retention and insulation degradation over time. Furthermore, purchasing sleeves that are pre-slit can save time during installation.

Equally important is understanding the specific diameter of the pipes being insulated. Incorrect measurements could lead to improper fitting and reduced thermal efficiency. Therefore, using a measuring tape to accurately gauge the circumference of the pipes is a significant first step toward successful installation.

2. DETERMINE LENGTH AND SIZE

Accurate measurement of the pipes for solar thermal applications is vital. To achieve optimal insulation performance, the rubber sleeve should entirely cover the exposed sections of the piping system. For this, it is essential first to measure the length of the pipe that requires insulation. Measuring along the pipe’s entire length with the measuring tape will ensure that the insulation sleeve covers all necessary areas.

Furthermore, assessing the width of the pipe will provide insights into the appropriate diameter of the insulation sleeve. Selecting the right sleeve diameter is foundational; if the sleeve is too small, it fails to fit adequately, while an oversized sleeve may leave parts of the pipe unnecessarily exposed.

Upon determining the appropriate dimensions, cutting the rubber sleeve to size is necessary. It’s prudent to add a little extra length to account for any potential installation errors or unforeseen needs. Once the cutting is done, placing the pieces to the side ensures easy access during the installation process, ultimately streamlining efficiency.

3. SURFACE PREPARATION

Preparation of the surface where insulation sleeves will be applied plays a crucial role in ensuring the adhesive bonds effectively. Cleaning the surface properly removes any dust, dirt, or oil that may impair adhesion. Utilizing a damp cloth or sponge is recommended for this task, ensuring the pipe is not only clean but dry before proceeding.

Inspecting the pipes for any pre-existing damage is equally important. Any nicks, dents, or other irregularities could obstruct the insulation process. For instance, if there are cold patches or signs of water accumulation, it is crucial to rectify these issues before proceeding.

Subsequently, any necessary repairs should be undertaken before moving on to insulation. This ensures that the integrity of the insulation is maintained over time, preventing potential losses in thermal efficiency due to existing issues on the pipes.

4. POSITIONING THE SLEEVE

With the surface adequately prepared, the next stage involves positioning the rubber insulation sleeve around the pipe. Meticulousness is key during this phase. Start by gradually unrolling the rubber sleeve, carefully aligning it so the ends meet at the pipe’s entry point. The sleeve should not twist or crumple; any irregular placement can hinder the thermal insulation.

Next, slowly press the rubber sleeve down into place along the pipe. This ensures a snug fit that will effectively retain heat. If the insulation sleeve comes with a self-adhesive side, peel off the backing and press the sleeve firmly against the pipe, ensuring there are no voids or air pockets, as these could lead to energy losses.

If the sleeve does not have an adhesive side, use either the adhesive tape or sealant to secure the insulation in position. Verify that the entire length is covered adequately, providing maximum protection against thermal loss. Lastly, inspect your work meticulously for any misalignments or areas that require adjustments.

5. SECURING AND FINISHING

Once positioned properly, securing the insulation is paramount for long-term efficiency. Using adhesive tape, carefully wrap around both ends of the rubber sleeve; this provides additional support and helps maintain position even under varying temperature conditions. Additionally, using sealant can be beneficial in ensuring the seams are watertight, preventing moisture infiltration that could degrade the insulation over time.

It is recommended to double-check the tension applied to the tape or sealant used. Excessive pressure may distort the sleeve, while inadequate sealing could permit air leaks. Both scenarios can diminish the overall effectiveness of the insulation.

Another important aspect is proper insulation finishing. Cutting excess material neatly with a utility knife can enhance appearance and efficiency. Ensure that the sleeve’s finish is even and trimmed to promote an aesthetically pleasing installation while maintaining effectiveness. Properly finished insulation can prevent future complications and enhance the system’s performance capability.

6. FINAL INSPECTION AND MAINTENANCE

A thorough final inspection is essential after installation. Carefully check for gaps, misalignment, or areas that may need further reinforcement. Identifying and correcting imperfections before the system is operational can prevent future inefficiencies and costly repairs.

A regular maintenance schedule should be established to ensure that the insulation remains intact and effective over time. Making periodic checks can identify any wear and tear or damage that might have developed. Inspection is particularly crucial in environments with extreme temperatures or variable weather conditions.

Moreover, understanding the best practices for maintaining insulation will extend its lifespan and performance. Cleaning any debris from the exterior of the insulation can prevent heat loss due to build-up. A proactive approach stimulates longer-lasting energy savings and keeps the system functioning optimally.

7. FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF INSTALLING SOLAR THERMAL INSULATION RUBBER SLEEVES?

Installing solar thermal insulation rubber sleeves offers numerous advantages. They are designed to optimize energy efficiency, significantly reducing heat loss during fluid transport. This leads to improved overall performance of a solar thermal system, allowing it to operate more effectively. Furthermore, insulated pipes contribute to maintaining the temperature of the fluids, which can yield increased energy savings over time. Consistent temperature can also prolong the lifespan of the system components by reducing strain.

In addition, efficiency in thermal retention can greatly influence cost savings. Properly insulated systems use less energy, translating to lower utility bills. Finally, this insulation provides a protective layer against external environmental factors, reducing the chances of damage from extreme temperatures or weather conditions.

HOW DOES WEATHER AFFECT SOLAR THERMAL INSULATION?

Weather has a profound impact on solar thermal insulation. Extreme temperatures, whether exceedingly hot or cold, can adversely affect the integrity of the insulation materials. For instance, excessively high heat can cause materials to degrade over time, leading to potential wear that would necessitate replacement.

On the other hand, cold weather can encourage condensation within uninsulated pipes. If water seeps into areas of insulation, this can lead to weakened efficiency and potential mold growth. In regions with substantial weather fluctuations, maintaining insulation integrity becomes even more critical.

Additionally, rain and moisture can also infiltrate unsealed areas of insulation. Installing sleeves that are effective against water ingress ensures that the insulated pipes perform effectively despite the prevailing weather conditions. Therefore, understanding the interaction between weather elements and insulation is vital for optimal thermal performance.

WHAT MATERIALS ARE USED IN SOLAR THERMAL INSULATION RUBBER SLEEVES?

Solar thermal insulation rubber sleeves are typically made from specialized thermal rubber or silicone-based materials. These materials are designed to withstand high temperatures while providing excellent thermal resistance. The insulation quality often depends on the material composition, with higher-grade materials exhibiting superior performance.

Moreover, many manufacturers incorporate additional features like UV resistance or extra additives for enhanced longevity. These features protect against degradation from sun exposure and ensure the insulation remains effective over extended periods. The combination of high durability and effective insulation performance makes these rubber sleeves particularly valuable in solar thermal applications.

In summary, the installation of solar thermal insulation rubber sleeves involves meticulous preparation, precise measurements, and appropriate securing techniques. This ensures that thermal efficiency is maximized within the solar system, ultimately leading to better energy savings and enhanced system reliability. Conducting regular maintenance checks further preserves insulation integrity and system performance. Engaging with these practices not only safeguards the investment in the solar thermal system but also contributes toward a more sustainable energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-thermal-insulation-rubber-sleeve/