To effectively install solar thermal insulation elbows, it is essential to follow systematic procedures that ensure optimal performance and durability of the system. 1. Purpose of solar thermal insulation elbows is significant for both conserving energy and ensuring the efficiency of the heating system, particularly in solar thermal setups. 2. Adhering to safety protocols throughout the installation process is paramount, minimizing risks associated with handling tools and materials. 3. Understanding the compatibility of elbows with existing piping and insulation materials optimizes energy transfer and ensures system integrity, as mismatched components can lead to inefficiencies. 4. Regular maintenance checks following installation prolong the lifespan of the solar heating system and enhance its efficiency, highlighting the importance of ongoing care.

Attention to these elements during the installation of solar thermal insulation elbows can lead to a successful project. It’s advisable to consult with professionals who can provide tailored guidance based on specific system requirements.

1. UNDERSTANDING SOLAR THERMAL SYSTEMS

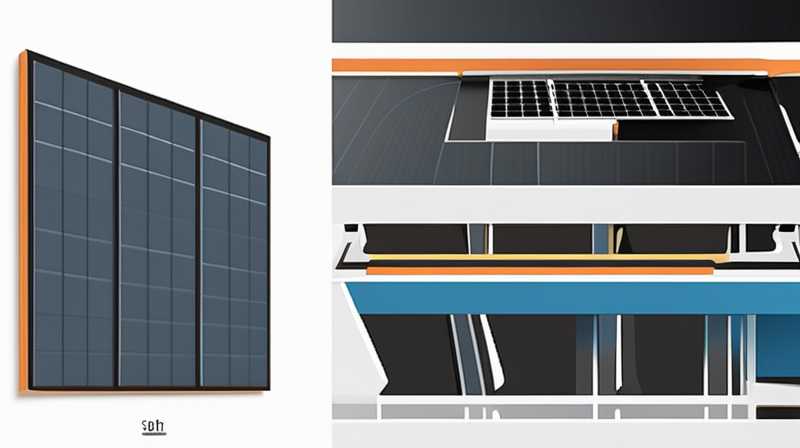

Solar thermal systems harness solar energy to provide heating, often utilized for residential and commercial hot water supply or space heating. These systems generally consist of solar collectors, which capture sunlight, and a heat transfer medium, typically water or antifreeze, that carries the absorbed heat to storage tanks or heating systems. The integration of solar thermal insulation elbows plays a crucial role in ensuring that the heat transfer process is efficient and minimizes heat loss, which can significantly impact system efficiency.

In a typical solar thermal setup, elbows are required to connect straight sections of piping, directing the flow of heated liquid toward heating storage or usage points. Proper insulation of these elbows is essential because uninsulated or poorly insulated connections can result in substantial heat loss. By installing thermal insulation on elbows, homeowners and system operators ensure that the heat transfer medium maintains its temperature as it travels through the piping system. This is particularly critical during colder months, where external temperatures can drastically reduce the effectiveness of a solar heating setup.

2. TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

To undertake the installation of solar thermal insulation elbows, a variety of tools and materials are necessary. 1. Essential tools for the installation include pipe cutters, wrenches, screwdrivers, utility knives, and measuring tape, which allow for precise cutting and assembly of the piping system. 2. Materials required encompass insulation sleeves or wraps specifically designed for solar thermal applications, along with the appropriate elbow fittings, sealants, and fasteners. These components work together to create a comprehensive insulation solution that minimizes heat loss.

Before commencing installation, it is vital to gather all necessary tools and materials to ensure a smooth working process. Preparation is key; ensuring that all tools are in good condition and materials are compatible with existing systems can streamline the installation. Furthermore, reviewing installation guidelines and manufacturer recommendations will provide useful insights into specific requirements for the elbows and insulation being utilized. Preparing for contingencies, such as having additional fittings on hand, can prevent delays during installation.

3. STEP-BY-STEP INSTALLATION PROCESS

a. MEASURING AND CUTTING

Accurate measurement is the foundation of a successful installation. Begin by measuring the lengths of pipe that the insulation elbows will connect. Mark each section clearly to ensure precision when cutting. Using a pipe cutter, carefully cut the sections to the required lengths, making sure the cuts are straight to avoid any misalignment during assembly.

Once the pipes are cut, it’s time for the installation of the elbows. Ensure that the ends of all piping sections are free from burrs or debris, which can impede proper sealing. A clean, flat surface ensures that the elbow fittings can be securely connected without any gaps. After preparing the pipe ends, affix the elbows securely, ensuring they align properly according to the system’s design. This step is crucial, as misalignment can lead to inefficiencies or potential leaks.

b. APPLYING INSULATION

With the elbows securely connected, the next phase involves insulation. Start by selecting insulation sleeves or wraps designed for high-temperature applications. Carefully slide the insulation over each elbow, ensuring that it covers all exposed areas. This step is essential to minimize heat loss as the heated fluid travels through the elbows.

When wrapping with insulation, ensure a snug fit. Overlap any seams carefully to create a continuous insulating layer, which helps maintain temperature consistency throughout the piping system. Utilize sealants or adhesive materials where necessary to secure the insulation in place, making the installation more robust and resistant to environmental influences.

4. TESTING AND FINALIZING INSTALLATION

Once the insulation is applied, testing the installation is crucial. Open any valves and allow the system to fill with the heat transfer medium, monitoring for any signs of leaks, particularly at the elbow joints. This initial testing phase helps identify any potential issues before the system is fully operational.

After conducting successful testing, finalize the installation by securing all insulation materials properly. Inspect all connections and ensure that they are tight and adequately sealed to promote efficiency. It is prudent to conduct a final visual check to ensure everything is in order before considering the installation complete. After confirming that the system operates efficiently, document the installation process and keep records of materials for future reference, as this can assist with repairs or upgrades.

5. REGULAR MAINTENANCE AND INSPECTIONS

Once the system is up and running, regular maintenance is important to ensure its longevity. Schedule inspections at least once a year, checking for signs of wear and tear on the insulation and connections. During these maintenance checkups, pay close attention to the elbows and insulated sections, as these are often vulnerable to environmental factors.

Cleaning the exterior of the insulation, along with inspecting it for any signs of damage, should be part of routine upkeep. In the case of visible deterioration, replace insulation to prevent energy losses. Additionally, monitoring fluid levels and functionality of the entire system can help maintain optimal performance and prevent costly repairs in the long run.

Various factors can influence the efficiency and effectiveness of solar thermal systems. Thus, being proactive about maintenance and inspections not only prolongs the lifespan of the installation but also enhances the overall efficiency of the solar heating system.

FREQUENTLY ASKED QUESTIONS

HOW LONG DOES IT TAKE TO INSTALL SOLAR THERMAL INSULATION ELBOWS?

The duration for the installation of solar thermal insulation elbows can vary based on multiple factors. Typically, the process involves initial preparation, measuring, cutting, fitting elbows, insulating, and finally testing the entire system. On average, a skilled technician can complete the installation within a span of four to six hours. This estimate might be subject to the size of the system, complexity of the layout, and the technician’s proficiency.

For smaller systems with fewer elbows, the installation could be completed more swiftly. Additionally, if prior plumbing experience is available, the time required might be reduced significantly compared to those unfamiliar with pipe systems. It’s advisable to allocate additional time for unforeseen challenges, such as misaligned pipes or the need for additional materials, as these can extend the process unexpectedly. All parties involved should ensure sufficient preparation before initiating the installation to minimize delays.

WHAT MATERIALS ARE BEST FOR INSULATING SOLAR THERMAL ELBOWS?

Selecting suitable insulation materials for solar thermal elbows is vital for optimal performance. Common insulation solutions include fiberglass, foam rubber, and rigid foam boards, all of which provide excellent thermal resistance when applied correctly. Each material choice has its advantages and drawbacks, and consideration should be given to the specific conditions of the installation environment.

Fiberglass is a popular choice due to its effectiveness in high-temperature applications and durability against environmental factors. It’s essential to use closed-cell foam insulation in outdoor applications, as this type helps prevent condensation and moisture build-up. Rigid foam boards are another excellent option, particularly for larger installations, as they provide high insulation values while being easier to install around various configurations. It is suggested to select insulation materials with adequate temperature ratings to ensure they can withstand the heat typically present in solar thermal systems, thus prolonging the system’s efficiency over time.

IS PROFESSIONAL INSTALLATION NECESSARY FOR SOLAR THERMAL INSULATION ELBOWS?

While some homeowners may be inclined to undertake the installation as a DIY project, professional installation is highly recommended for solar thermal insulation elbows. Skilled technicians possess the experience and knowledge to navigate potential challenges effectively, ensuring that the installation meets industry standards. Proper training allows professionals to adhere to safety protocols, providing peace of mind throughout the process.

The complexity of solar thermal systems often warrants the expertise of trained personnel, as errors during installation can lead to inefficiencies or require costly repairs down the line. Moreover, professional installations are frequently backed by warranty guarantees that offer added protection should complications arise later. Employing qualified professionals allows homeowners to benefit from their expertise, ensuring that the system operates optimally from the outset.

Effective installation of solar thermal insulation elbows is critical for maximizing the efficiency of solar heating systems. Through careful measurement, selection of quality materials, and adherence to maintenance practices, users can significantly enhance performance while extending the system’s operational lifespan. Understanding the intricacies of the installation process allows individuals to appreciate the investment in solar energy systems, realizing both economic and environmental benefits.

Furthermore, regular checks and adjustments post-installation remain integral to maintaining peak performance. Whether undertaking a DIY approach or engaging professional services, the focus should be directed toward meticulous preparation and execution of the installation process. Emphasizing the importance of quality materials, adherence to safety guidelines, and a commitment to ongoing maintenance will resonate well in the pursuit of energy sustainability and efficiency. By embracing these elements, solar thermal systems can provide reliable, energy-efficient solutions for heating water and space, effectively supporting a greener lifestyle.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-thermal-insulation-elbow/