To successfully install a solar sealing roll, one must consider several essential aspects. 1. Preparation of the installation area, 2. Selection of the right materials, 3. Step-by-step application process, 4. Maintenance and inspection procedures. Among these points, the preparatory work is critical. Ensuring that the surface where the sealing roll will be applied is clean, dry, and smooth helps promote optimal adhesion and longevity of the installation. A proper preparation lays the foundation for effective results and enhances the performance of solar sealing rolls.

1. PREPARATION OF THE INSTALLATION AREA

An essential component of the installation process involves ensuring the area is primed appropriately, setting the stage for application. First and foremost, the surface must be evaluated for cleanliness to eliminate debris, dirt, and any elements that could hinder the performance of the sealing roll. A clean surface enhances adhesion and ensures that the sealing roll functions effectively.

Cleaning methods can vary based on the type of surface used, whether it be metal, concrete, or another material. For metal surfaces, employing a degreaser or appropriate solvent will remove oils and residue. Similarly, concrete surfaces may require pressure washing to remove any loose material. In some cases, using a wire brush to scrub stubborn spots may also be beneficial. Taking the time to perform this cleaning task thoroughly will significantly impact the quality of the installation.

Once the surface is clean, it’s equally crucial to dry the area completely. Moisture can severely compromise the adhesive properties of the solar sealing roll. After cleaning, allowing adequate time for drying ensures that any remaining humidity is eliminated. Depending on local weather conditions, drying might take longer in damp or humid climates.

Additionally, inspecting the surface for any damage or imperfections is imperative. Any cracks, pits, or irregular areas may need repair before the installation of the sealing roll can proceed. Applying a filler to smooth out these imperfections will create a more even surface, further enhancing the overall effect of the sealing roll. This detailed attention to preparation contributes significantly to the longevity and efficiency of the solar sealing roll.

2. SELECTION OF THE RIGHT MATERIALS

The market for solar sealing rolls offers a variety of options, each suited for different applications and environments. Selecting the appropriate materials is a vital step in ensuring a successful installation. An understanding of the specific requirements, such as weather resistance, thermal expansion, and compatibility with existing structures, will guide this decision.

One primary type of material utilized in solar sealing rolls is EPDM rubber, known for its durability and excellent weather resistance. EPDM sealing rolls can withstand temperature extremes, making them ideal for regions with significant temperature fluctuations. Furthermore, this material possesses ultraviolet resistance, which is essential for longevity, particularly in outdoor applications.

Another commonly used material is silicone. Silicone seals exhibit flexibility and excellent adhesion characteristics, making them ideal for areas exposed to movement or vibration. They effectively accommodate structural shifts, which is especially important in solar energy installations where foundational movements may occur over time.

In addition, one should consider the adhesive properties of the sealing roll. Choosing a self-adhesive option can significantly reduce installation time and complexity. Self-adhesive rolls often already come with a peel-off backing, allowing for easy application. This feature greatly benefits users lacking expertise in sealing techniques, as it simplifies the installation process.

When selecting the right materials, it is also important to consider environmental aspects. Some materials may take longer to decompose and adversely affect the environment. Opting for eco-friendly materials not only contributes to sustainability but can also enhance the reputation of the installation overall. By keeping these considerations in mind, informed choices can be made that contribute to a successful solar sealing roll installation.

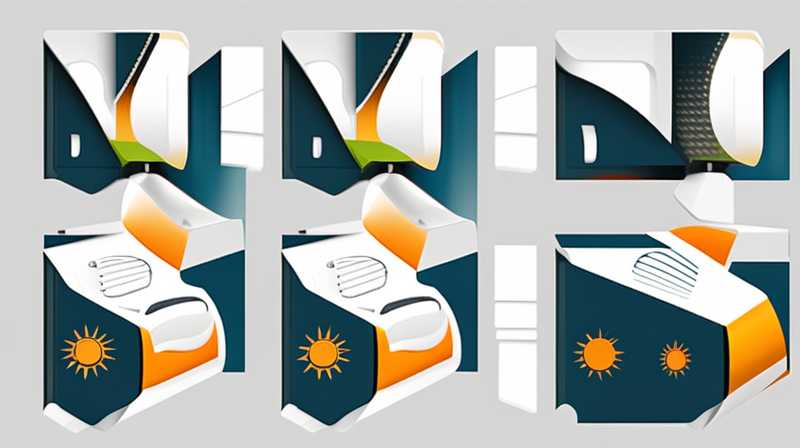

3. STEP-BY-STEP APPLICATION PROCESS

Once the preparation and material selection are complete, one can proceed with the installation process. Comprehensive understanding of each step is vital to achieving optimal results. Ensuring that all necessary tools and materials are on hand will facilitate a smoother workflow. Common tools used in the installation process include utility knives, rollers, and measuring tapes.

The application process begins with measuring the area where the sealing roll will be applied carefully. Accurate measurements prevent material wastage and ensure that the roll fits perfectly in the designated space. It is advisable to mark out the dimensions clearly on the surface using chalk, making it easier to align the roll during installation.

After marking, the next step involves cutting the solar sealing roll to the necessary length. Utilizing a sharp utility knife will provide clean edges, essential for a seamless fit. Any frayed edges may lead to ineffective sealing, so precision during cutting is necessary. Work steadily to minimize mistakes, as incorrect cuts can result in added labor and increased costs.

Following the cutting process, the installation commences with peeling off the backing paper from the adhesive side. It is crucial to adhere the roll directly to the beginning of the marked line without touching any contaminants. The initial positioning is fundamental, as any misalignment can pose complications in the later stages. Applying the roll gently but firmly will assist with accuracy.

Once aligned, press the roll down using a roller to ensure it adheres to the surface uniformly. This step is vital for a strong bond; the adhesive must contact the entire surface area for an effective seal. Be sure to apply enough pressure without damaging the roll itself, ensuring that air bubbles do not form underneath. Special attention should be given to the edges, as they often require additional sealing to prevent moisture ingress.

After pressing the roll firmly, the final touch involves performing an inspection of the installation. Looking for gaps or misalignments will aid in enhancing the overall effectiveness of the sealing process. If any imperfections are noted, small adjustments can be made promptly before the adhesive sets completely.

4. MAINTENANCE AND INSPECTION PROCEDURES

Effective maintenance is essential to prolonging the life of the solar sealing roll installation. Routine inspections should be conducted to assess the sealing’s condition and integrity. Regular checks may help identify any signs of wear or degradation before they escalate into larger concerns.

At least twice a year, conduct an inspection of the sealing. Looking for cracks, gaps, or lifting from the substrate will provide essential insights into its condition. Should any issues be observed, taking prompt corrective action is vital. Minor repairs can usually be accomplished with adhesive or supplemental sealing, thereby preventing further damage.

Environmental factors can significantly impact the lifespan of sealing materials. Prolonged exposure to intense UV rays, moisture, and extreme temperatures may contribute to faster degradation. Keeping track of weather conditions and preparing for seasonal changes can bolster the longevity of the installation. In regions with severe seasonal variances, planning for additional protective measures is advisable.

Cleaning the surface periodically is equally critical. Dirt, debris, and organic growth can accumulate over time, potentially compromising the sealing’s performance. Utilizing pressure washing or mild cleaning solutions can help maintain a clean surface. Avoid abrasive tools that may damage the sealing material during cleaning.

Lastly, documentation of inspections and maintenance activities can provide invaluable records over time. Keeping a log of maintenance actions serves both as a reminder for future inspections and a checklist for repairs. This practice can also assist in identifying patterns in performance, providing insights into when replacement may be warranted in the future.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR SEALING ROLL?

A solar sealing roll is a type of flexible material utilized for weatherproofing and insulating solar-powered installations. Generally composed of durable materials such as EPDM rubber or silicone, these rolls provide effective sealing against moisture infiltration. Installation involves adhering the roll along seams, edges, and other vulnerable areas in solar setups, helping to enhance their longevity and energy efficiency.

Solar sealing rolls are especially effective in protecting photovoltaic systems and solar thermal installations from environmental elements, including rain, wind, and snow. By preventing water ingress, these sealing materials assist in maintaining optimal operational efficiency, thereby protecting the investment made in solar technology. Additionally, regular maintenance of the seals may extend their lifespan, ensuring that solar installations continue to perform efficiently.

HOW LONG DOES A SOLAR SEALING ROLL LAST?

The longevity of a solar sealing roll can vary based on several factors, including material type, environmental exposure, and installation quality. Generally, high-quality materials like EPDM and silicone can withstand the elements for a period ranging from 10 to 20 years, depending on the specific conditions they face. Consistent maintenance and inspections play a crucial role in ensuring that the sealing rolls last as long as possible.

Factors that may impact the lifespan include UV exposure, temperature fluctuations, and moisture levels in the installation environment. In regions characterized by extreme climates or frequent weather changes, the roles may require additional attention to maintain their effectiveness. Regular inspections can identify potential damage early, allowing for repairs and extending the roll’s life.

CAN I INSTALL A SOLAR SEALING ROLL MYSELF?

Yes, many individuals opt for self-installation of solar sealing rolls, provided they follow clear instructions and attend to the necessary precautions. Having a basic understanding of the installation process and possessing the right tools is essential for achieving a successful installation. Detailed guides and tutorials are readily available, assisting those without prior experience.

However, it’s important to recognize one’s comfort level and capabilities. For individuals unfamiliar with construction materials or processes, seeking professional assistance may be advantageous. A professional can ensure that the work meets industry standards and can address unexpected issues that may surface during the installation. Ultimately, the choice of self-installation versus professional help will depend on individual skills and the complexity of the project at hand.

The effective installation of solar sealing rolls not only enhances energy efficiency but also extends the service life of solar-powered systems. Attention to detail during preparation, material selection, application, and maintenance contributes to optimal performance. By adhering to the outlined processes and continuously monitoring the condition of installed sealing rolls, one can achieve long-lasting results. Understanding specific roles and functionalities, coupled with consistent upkeep, ensures that these systems remain resilient against the elements, ultimately fostering a sustainable approach to energy consumption. Furthermore, as solar technology continues to advance, embracing proper sealing techniques will become increasingly pivotal in maximizing output and efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-sealing-roll/