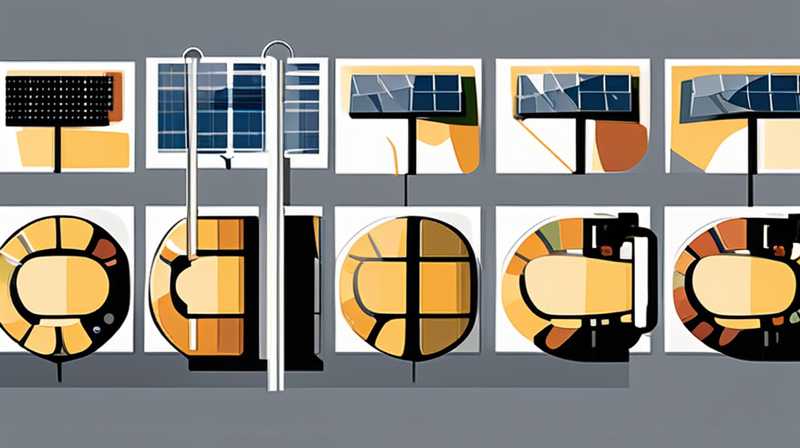

The process for installing solar lights on harvesters involves several critical steps: 1. Identify the optimal locations for placement, 2. Gather necessary tools and materials, 3. Prepare the surface for installation, and 4. Ensure proper wiring and functionality of solar lights. Step one requires evaluating areas on the harvester that will allow for maximum exposure to sunlight while being mindful of the operational aspects of the machinery involved. The installation of solar lights significantly enhances visibility during nighttime operations, increasing safety and efficiency.

1. IDENTIFYING OPTIMAL LOCATIONS FOR SOLAR LIGHTS

Ensuring appropriate placement of solar lights is paramount for maximizing their functionality. The objective is to position these lights in areas receiving ample sunlight exposure during the day. While it might be tempting to install them wherever it seems convenient, careful consideration should be given to how shadows cast by the harvester and adjacent structures may diminish light absorption. Additionally, lights should be placed where they can illuminate the work zones effectively without hindering operational capabilities.

Proper locations may include the top of the harvester cab, above critical working components, areas that require visibility for safety, and places where illuminating the immediate surrounding environment is essential. This positioning can significantly enhance nighttime visibility, making it easier for operators to navigate and operate equipment safely, especially in low-light conditions. Analyze how these areas correspond to machinery operational zones to prevent any interference during harvesting activities.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Preparation is vital, so gathering all required tools and materials can streamline the installation process. Essential tools typically include screwdrivers, wrenches, a drill, and possibly a level for ensuring precision. For materials, one must select solar lights, which may vary in size, brightness, and mounting capabilities. Researching and choosing energy-efficient solar lights designed for agricultural machinery is advisable, as these will withstand the rigors of outdoor environments.

Having all items ready in advance facilitates a smoother installation experience. Consider any additional features, such as motion sensors or remote controls, that may enhance functionality. Furthermore, choosing solar lights with durable housings and weather-resistant capabilities is essential. These factors contribute significantly to the longevity and reliability of the lights installed on your harvester, ultimately leading to better operational efficiency.

3. PREPARING THE SURFACE FOR INSTALLATION

Once locations are determined and materials are assembled, preparing the surfaces for installation becomes crucial. This preparation may involve cleaning the areas to ensure no dirt, debris, or old components obstruct the mounting of the lights. Proper surface treatment also ensures a secure attachment, which is critical in preventing the lights from dislodging during operation.

If mounting on metal surfaces, it may be advisable to use rust-inhibiting primers or adhesives to promote longevity. For surfaces made of plastic or fiberglass, selecting compatible mounting materials is wise, as these can significantly affect the durability of the installation. This step may seem minor, but the quality of the surface preparation can prevent premature failures of the solar lights installed.

4. ENSURING PROPER WIRING AND FUNCTIONALITY

Once lights are securely mounted, the importance of proper wiring cannot be overstated. If the solar lights come with battery systems, ensuring the batteries are correctly installed and secured is critical. Improper wiring may not only hinder the lighting function but may also pose safety risks due to potential electrical issues.

Evaluating the functionality of the solar lights post-installation is essential. This process typically includes testing the solar connection during the day to confirm that the lights are charging adequately. Moreover, conducting a functional test at night allows for verification that lights illuminate as intended. Ensuring optimal performance and addressing any initial issues swiftly will ensure that the equipment operates without complications.

FREQUENTLY ASKED QUESTIONS

HOW DO SOLAR LIGHTS WORK ON HARVESTERS?

Solar lights operate based on solar energy captured through photovoltaic cells. During daylight, sunlight is absorbed and converted into electricity, which is then stored in built-in batteries. As night falls, these batteries power the lights, providing illumination without relying on external electric sources. Since harvesters often operate in remote fields without access to electricity, solar-powered lights present an effective solution to enhance visibility and safety. This energy independence also means ongoing maintenance costs are lower; operators do not have to worry about purchasing fuel or electricity to power their lights. Furthermore, the environmental advantages of using solar energy contribute positively to sustainability in agricultural practices, making solar lights a fitting choice for modern harvesters.

WHAT FACTORS IMPACT THE PERFORMANCE OF SOLAR LIGHTS?

Several factors play a crucial role in determining the performance of solar lights on harvesters. The geographical location significantly influences how much sunlight the solar panel can absorb; areas with prolonged cloudy days or inclement weather might experience reduced efficiency. Moreover, the positioning of the lights can impact their ability to gather sunlight—if they are in shaded regions, they might not charge fully, leading to dim output during nighttime. The quality of the solar panels and batteries also affects performance; high-quality materials typically perform better and withstand extreme outdoor conditions for more extended periods. Lastly, ensuring proper installation without any obstructions will prevent premature wear and tear, maintaining optimal functionality over the lifespan of the solar lights installed.

CAN SOLAR LIGHTS HANDLE INCLEMENT WEATHER?

Solar lights are designed with weather resistance in mind, especially for agricultural applications where various climatic conditions may exist. Most solar lights built for outdoor use feature casings that protect against rain, wind, and extreme temperatures. When selecting solar lights, checking the IP rating (Ingress Protection) can provide insights into how well the light can withstand moisture and dust. An IP65 rating or higher is generally desirable for successful outdoor usage.

Nevertheless, it is essential to follow appropriate installation recommendations, which may include utilizing additional protective measures near high-exposure areas, such as the edges of the transformer components or wiring. Proper maintenance—such as periodic cleaning of the solar panels—can further enhance the durability and effectiveness of these lights, ensuring they perform optimally regardless of weather conditions.

FINAL REMARKS

The installation of solar lights on harvesters represents both an innovative and practical enhancement to agricultural operations. The effectiveness of this process hinges on a few core principles: making informed decisions about placement, securing high-quality materials, ensuring proper preparation and installation, and conducting thorough tests of functionality. Each of these aspects demands attention to detail, as even minor oversights can lead to significant drawbacks in safety or efficiency. Investing time and resources into proper setup will not only yield immediate benefits in terms of visibility but will also contribute positively to the long-term operational viability of harvesting tasks. This proactive approach can prove invaluable in maximizing productivity, granting operators the confidence to work effectively in low-light environments. As the agricultural industry continues evolving, the adoption of sustainable practices such as solar lighting becomes increasingly critical, paving the way toward a greener, more efficient future. By embracing these advancements, farmers and operators can enhance their safety while simultaneously contributing to environmental sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-lights-on-harvesters/