To effectively install solar lamps in factories, one must consider the following main components: 1. Assess the location and requirements, 2. Select appropriate solar lamp models, 3. Prepare for installation, 4. Carry out the installation process, 5. Conduct maintenance checks. The installation setup begins with a thorough evaluation of factory premises to determine the optimal energy sources and lamp placement, which is crucial for maximizing efficiency and achieving desired lighting levels.

1. ASSESSING THE LOCATION AND REQUIREMENTS

Thoroughly examining the factory’s layout and operational aspects is essential before initiating any installation of solar lamps. The primary objective is to identify areas that require illumination during non-daylight hours, promoting safety and productivity within the workspace. Lighting requirements often differ based on various factors including area size, intended use, and existing light sources. Conducting a detailed survey assists in understanding the factory environment and highlights specific zones where additional lighting is critical.

Furthermore, analyzing the surrounding environment plays a pivotal role. Factors such as nearby obstructions, existing electricity sources, and the amount of sunlight received in different seasons impact the efficiency of solar lamps. Factories situated in locations with minimal sunlight exposure should consider using larger or more advanced models with enhanced battery capacities. Understanding these nuances ensures one can determine the optimal number of lamps needed and their placements to ensure uniform light distribution across the factory floor.

2. SELECTING APPROPRIATE SOLAR LAMP MODELS

After understanding the location and requirements, choosing the right solar lamp models tailored to these needs proves essential for effective installation. Different models boast distinct features and specifications designed for varying applications. Certain lamps are better suited for illuminating broader areas with high lumens output while others may focus on providing sustained light over extended periods.

When exploring options, factors such as battery capacity, solar panel efficiency, and construction materials should be prioritized. High-quality solar lamps typically come equipped with durable, weather-resistant materials to withstand industrial environments. Examining manufacturer specifications allows a firm to select lamps that not only meet illumination requirements but also fit within budgetary constraints. It is also beneficial to consult with suppliers who can provide valuable insights regarding the best options available in the market, ensuring a well-informed purchase decision.

3. PREPARING FOR INSTALLATION

Preparation is a critical stage in the installation of solar lamps, as it can greatly affect the overall success of the project. Adequate assessment of required tools and materials is essential. Essential tools may include drilling equipment, measuring tapes, levelers, and safety gear to ensure a safe working environment is maintained throughout the installation process. Securing the necessary equipment beforehand minimizes interruptions and ensures a seamless operation.

Moreover, scheduling the installation during non-operational hours proves beneficial for both efficiency and employee safety. Assessing potential obstacles and working in harmony with existing factory operations leads to enhanced cooperation among team members. During the preparation stage, establishing a clear line of communication among the workers involved ensures that everyone understands their roles and responsibilities, resulting in a more coordinated effort during installation. This level of foresight fosters a collaborative atmosphere that can handle unexpected challenges effectively.

4. CARRYING OUT THE INSTALLATION PROCESS

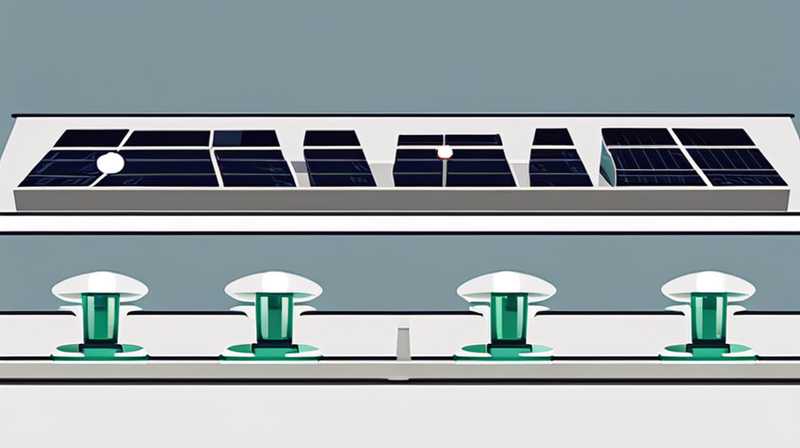

The moment of truth arrives when the installation process begins, as this is when planning and preparation culminate in action. The process generally starts with site marking, where intended lamp positions are outlined based on the earlier assessment. Proper alignment is vital to achieve uniform lighting in all targeted zones. Using measuring tools ensures accuracy, contributing to a professional-looking setup.

Once the site marking is complete, drilling the mounting holes for solar panel installations follows. Careful attention should be given to the angle of the solar panels, as their direction greatly affects their performance. Ideal angle placements typically correspond to the latitude where the factory operates. Post drilling, securely attaching the solar lamps and fixtures, along with ensuring the proper arrangement of the solar panels, guarantees optimized energy absorption. Lastly, connecting all wiring in accordance with manufacturer guidelines is crucial to promoting safety and functionality.

5. CONDUCTING MAINTENANCE CHECKS

After the installation is successfully completed, regular maintenance checks are imperative to ensure the solar lamps remain operational and efficient. Cleanliness of solar panels is crucial, as dust buildup can significantly hinder performance. Scheduling periodic inspections allows crews to easily identify any issues arising, such as faulty connections or component failures, thereby leading to timely repairs.

Additionally, implementing a monitoring system helps factory management stay informed regarding energy output and any drop in performance metrics. Investing in a monitoring solution can proactively alert personnel to maintenance requirements and provide data analytics to track energy savings over time. This emphasis on maintenance not only maximizes lamp longevity but also sustains operational efficiency, ensuring a high level of workplace safety and illumination.

FREQUENTLY ASKED QUESTIONS

HOW DO SOLAR LAMPS WORK?

Solar lamps operate by converting sunlight into electricity through photovoltaic cells located in solar panels. During daylight, these panels absorb sunlight and transform it into electrical energy, which is stored in batteries for nighttime use. This stored energy powers the lamps, allowing them to illuminate designated areas once the surrounding light fades below a certain threshold. Many modern solar lamps come equipped with sensors that automatically activate the light when natural light is insufficient. This self-sustaining mechanism reduces reliance on grid electricity, making solar lamps an eco-friendly and cost-effective solution for factories.

WHAT FACTORS AFFECT THE PERFORMANCE OF SOLAR LAMPS?

Several factors can influence the performance of solar lamps installed in factory settings. Firstly, the availability of sunlight plays a crucial role, as ample exposure allows batteries to charge fully. If solar panels receive shade from surrounding structures or foliage, their efficiency diminishes, resulting in lower energy output. Additionally, the angle and positioning of solar panels significantly affect their ability to capture sunlight. Regular cleaning of panels is also necessary to eliminate dust or debris, which may obstruct solar energy absorption. Monitoring battery health and ensuring connections remain intact are critical for optimal operation.

CAN SOLAR LAMPS BE USED IN ALL WEATHER CONDITIONS?

While solar lamps are designed to withstand various weather conditions, there are certain limitations to their performance in extreme environments. Most models are built with weather-resistant materials to endure rain, snow, and high winds. Nevertheless, prolonged exposure to excessive moisture may affect their longevity if not adequately sealed. Additionally, extreme cold or heat can diminish battery efficiency, impacting the lamp’s output. Choosing models specifically designed for challenging weather can enhance performance and ensure the longevity of lamps when subjected to harsh conditions.

Reliable illumination within a factory setting is paramount for ensuring safety, productivity, and operational efficiency. Installing solar lamps offers an eco-friendly, sustainable solution to lighting needs. One must undertake a structured approach that includes evaluating site requirements, selecting suitable models, preparing meticulously, executing installation efficiently, and committing to ongoing maintenance. Taking these actions not only optimizes the benefits of using solar energy but also leads to significant financial savings over time, as operational costs linked to traditional energy sources diminish.

The intelligence of utilizing solar lamps lies in their ability to harness renewable energy, presenting an environmentally conscious alternative that supports sustainability efforts. As industries continually seek innovative ways to reduce their carbon footprint, solar lamp installations emerge as an essential strategy in this endeavor. The process of installation, while intricate, unfolded in a structured and strategic manner results in an effective lighting solution poised to withstand the test of time. Consequently, any factory that engages in this venture reinforces its commitment to sustainability, operational excellence, and enhanced worker safety.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-lamps-in-factories/