1. INSTALLATION OF SOLAR ELECTRIC HOIST REQUIRES CAREFUL PLANNING AND EXECUTION. The essential steps include a. selecting an appropriate location, b. securing necessary permits, c. ensuring power requirements are met, and d. performing a thorough safety check. Each of these points merits in-depth discussion to ensure optimal functioning and compliance with safety standards.

INSTALLATION PLANNING CONSIDERATIONS

Incorporating a solar electric hoist into your operations necessitates meticulous planning. It begins with selection, where the site must receive abundant sunlight, unobstructed by objects such as trees or tall buildings. This aspect cannot be overstated, as adequate sunlight exposure directly influences the efficiency and functionality of the installed system. Consideration of geographical factors, such as seasonal weather variations, can also impact performance. Additionally, the foundation on which the hoist will be mounted is equally critical. A stable and level surface prevents undue stress on the structure and the hoist mechanism, ensuring longevity and reduced maintenance requirements.

Choosing the right solar electric hoist goes beyond mere compatibility. It involves understanding the weight limits and lifting capacities of various models available on the market. Assessing load characteristics will guide appropriate selections, ensuring the hoist meets the demands of specific tasks without risk of failure. In-depth research into different brands and models is necessary, as products vary significantly in terms of durability, efficiency, and technological features.

REGULATORY AND SAFETY CONSIDERATIONS

Once a suitable location and equipment have been identified, compliance with local regulations is imperative. Securing the appropriate permits protects your investment and safeguards against legal issues. Regulations often dictate safety standards, electrical installation requirements, and local zoning laws. Therefore, liaising with local authorities, including building and safety departments, can provide clarity on any necessary procedural steps.

Safety checks encompass both the installation process and operational protocols. Integrated safety features, such as emergency stop buttons and built-in overload protection, enhance the system’s reliability and user safety. Additionally, creating an operational manual outlining safety procedures and emergency responses fosters a secure working environment. Upon completion of the installation, conducting a comprehensive safety assessment ensures that all operational elements function as intended.

INSTALLATION STEPS FOR SOLAR ELECTRIC HOIST

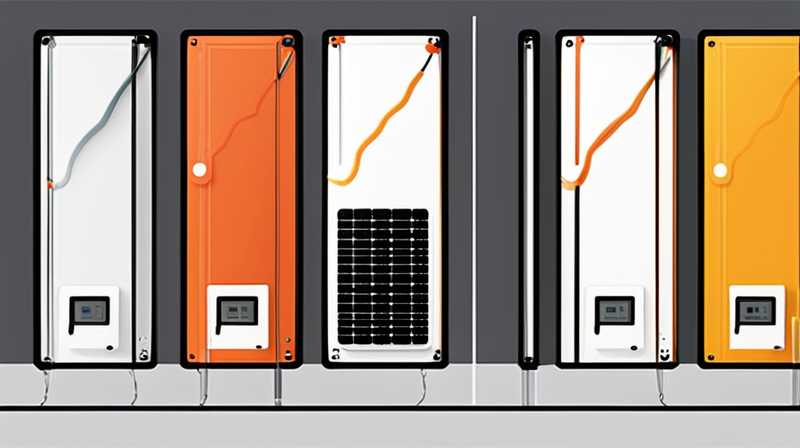

The installation process involves several critical steps to guarantee a successful arrangement. Beginning with the assembly of the hoist itself, follow the manufacturer’s instructions meticulously, adhering to any diagrams provided. This ensures that the hoist is constructed correctly, minimizing errors that could affect its functionality or safety. Tools such as wrenches, screwdrivers, and levels will play an essential role in ensuring stability and alignment.

Following assembly, mount the hoist securely to the previously prepared foundation. Proper anchoring methods based on the hoist’s specifications reinforce stability. Employing bolts, brackets, and other fastening devices will secure it effectively while providing necessary adjustments during positioning. Furthermore, attention should be paid to alignment with the load path, ensuring that no obstruction hampers its operation.

ELECTRICAL CONNECTIONS AND SYSTEM INTEGRATION

After structural assembly and mounting, focus shifts to the electrical aspects. Solar panels must be installed in a manner that maximizes sunlight exposure; this often involves determining the optimal angle and direction for installation. Utilize high-quality mounting systems to prevent damage due to wear or extreme weather conditions. Careful attention to cable management promotes efficiency and reduces the likelihood of damage.

Subsequently, connect the solar panels to the hoist’s battery system. Ensure that the wiring is properly insulated and secured, as short circuits can pose severe hazards and impair overall operation. Consideration should also be given to inverter systems if employing alternate energy conversion methods. Accurate integration of all components allows for seamless operation, maximizing efficiency with minimal risk.

MAINTENANCE PROFICIENCY FOR OPTIMAL PERFORMANCE

Regular maintenance is an indispensable part of operating a solar electric hoist. Establishing a scheduled maintenance routine ensures significant longevity and reduces the likelihood of unexpected breakdowns. Inspections should cover both mechanical and electrical components, including checking for signs of wear, corrosion, or environmental damage. Greasing moving parts and ensuring electrical connections remain secure are fundamental procedures that safeguard performance.

In addition to routine checks, addressing any issues immediately upon discovery diminishes the risk of exacerbated problems. Training staff on operational procedures and maintenance tasks enhances the hoist’s efficiency while ensuring compliance with safety protocols. This proactive approach fosters an environment of safety and efficiency, contributing to the overall productivity of your operations.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF USING A SOLAR ELECTRIC HOIST?

Embracing a solar electric hoist offers numerous advantages, significantly contributing to both operational effectiveness and environmental considerations. Firstly, the reliance on renewable energy minimizes operational costs associated with traditional electrical power. As energy prices fluctuate, solar energy provides a stable and sustainable source, ultimately affecting the budget positively over time. Moreover, the eco-friendliness of solar energy aligns with modern sustainability goals, enhancing your operation’s green credentials and public image.

From a functional standpoint, solar electric hoists often come with advanced features that maximize efficiency. Technological advancements have led to the incorporation of smart controls and monitoring systems, facilitating real-time assessments of performance and energy consumption. These features add layers of convenience and functionality, enabling users to engage with the equipment interactively. In conclusion, investing in a solar electric hoist not only enhances operational capability but also adheres to sustainable practices, reinforcing the importance of renewable energy.

HOW LONG DOES IT TAKE TO INSTALL A SOLAR ELECTRIC HOIST?

The duration for the installation of a solar electric hoist can significantly vary based on multiple factors, including complexity, site conditions, and team proficiency. On average, the process can take anywhere from a few days to a couple of weeks. Initial site preparation often requires time for assessment, preparation, and any necessary permitting processes before actual installation can commence. Furthermore, the experience level of the installation team plays a pivotal role in efficiency.

The assembly process itself typically ranges between one to three days, depending on the size of the hoist and associated systems. Securing solar panels and ensuring their optimal positioning may require additional time to evaluate the best local angles or addresses of any potential shading concerns. Once installed, testing and commissioning also necessitate time to ensure that all components interact seamlessly and any issues are rectified before transitioning to operational use.

WHAT MAINTENANCE TASKS ARE ESSENTIAL FOR A SOLAR ELECTRIC HOIST?

Maintaining a solar electric hoist is paramount for prolonging its lifespan and ensuring its operational effectiveness. Scheduled inspection routines are fundamental, focusing on both mechanical and electrical components. Regularly check for wear and tear in moving parts, as any degradation can lead to performance issues or safety hazards. Additionally, ensuring that all bolts and connections remain tight aids in maintaining stability.

Cleaning solar panels periodically is another critical aspect of maintenance. Accumulated dirt and debris can severely hinder performance by obstructing sunlight absorption, which directly impacts energy efficiency. A thorough inspection of wiring and electrical connections ensures that no damage or corrosion impairs functionality. By following these essential maintenance tasks, you optimize the operational capacity and enhance the longevity of the solar electric hoist.

ENSURING A SUCCESSFUL INSTALLATION OF A SOLAR ELECTRIC HOIST REQUIRES A MULTIFACETTED APPROACH. From meticulous planning and regulatory compliance to thorough installation and ongoing maintenance, each phase plays a vital role. Given the increasing reliance on renewable energy, employing solar electric hoists positions organizations as leaders in adopting sustainable practices. Additionally, proactive engagement in training, regular inspections, and operational best practices optimizes overall productivity. The transition to solar-powered systems not only saves costs but also contributes positively to the environment, fostering a broader cultural shift towards sustainability. Proper execution of each phase enhances safety standards and boosts efficiency while aligning operations with environmental objectives. Thus, organizations capitalizing on such advanced solutions can look forward to a successful and sustainable future in their operational endeavors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-electric-hoist/