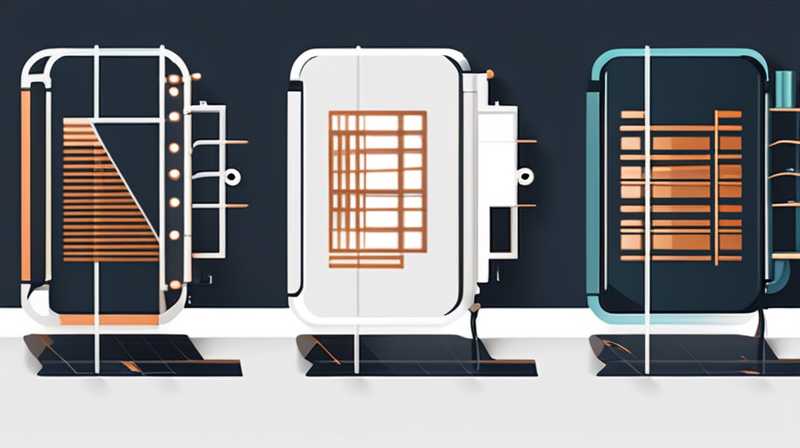

When it comes to the installation of solar copper joints, the process involves a series of precise steps to ensure successful integration into solar energy systems. Here are the essential components of the installation process: 1. Selecting Appropriate Materials, 2. Preparing the Workspace, 3. Proper Soldering Techniques, 4. Inspection and Testing Procedures. The selection of materials is critical as it affects the performance and longevity of the system. Using high-quality copper joints and connectors significantly enhances the conductivity and resilience of the electrical connections.

1. SELECTING APPROPRIATE MATERIALS,

In the journey of installing solar copper joints, the choice of materials plays a crucial role. Selecting high-quality copper components is of utmost importance, as they directly influence the performance and durability of solar power systems. Copper joints serve various functions, including interconnecting solar cells, linking modules, and enabling energy transfer. It’s essential to favor materials that meet industry standards and certifications to ensure long-lasting results.

Beyond copper joints, the choice of flux, solder, and other fittings is equally significant. Flux aids in the bonding process, preventing oxidation, and ensuring a clean solder joint. Using the correct solder formulated for electrical applications guarantees excellent conductivity and reduced resistance at electrical connections. Each of these components must be sourced from reputable suppliers to mitigate the risk of quality control issues and ensure compliance with safety regulations.

2. PREPARING THE WORKSPACE,

Preparation of the workspace is a fundamental phase in the installation process of solar copper joints. Creating a clean, organized, and well-ventilated area enhances focus and minimizes the risk of accidents or errors during installation. Adequate lighting is essential to clearly see small components, especially while soldering intricate joints.

Prior to starting any installation steps, all necessary tools and materials should be laid out in an accessible manner. Essential tools often include soldering iron, wire cutters, multimeter, and heat shrink tubing. Having these items on hand increases efficiency and reduces disruptions during work. Furthermore, it’s advisable to wear the appropriate safety gear, such as gloves and goggles, to protect against potential hazards associated with soldering and working with electrical materials.

3. PROPER SOLDERING TECHNIQUES,

Mastering soldering techniques is paramount to establishing quality connections within solar copper joints. Effective soldering involves several critical steps that demand precision and skill. A well-chosen soldering iron with the correct wattage is essential to achieve optimal heating without damaging the copper joints. Too much heat can lead to degradation of materials, while too little may not form a proper joint.

Initiate the soldering process by thoroughly cleaning all connection surfaces. This step prevents impurities that could weaken the bond and affect electrical performance. After cleaning, heat the connection point with the soldering iron to prepare it for solder application. Apply the solder gently until it flows smoothly into the joint. Observing the right amount of solder is important; excess can lead to short circuits, while too little may cause unstable connections. After completing the joint, allow it to cool naturally without disturbance to ensure structural integrity.

4. INSPECTION AND TESTING PROCEDURES,

Following the soldering phase, rigorous inspection and testing procedures should be followed to verify the integrity of all connections. Inspecting solder joints visually is a fundamental step; look for any signs of oxidation, weak flows, or inconsistencies that could indicate problems. Even the tiniest flaw can lead to significant electrical issues down the line.

Testing the connections with a multimeter is crucial to ensure proper functionality. By checking for continuity and confirming resistance levels, any anomalies can be identified early. A thorough testing protocol encapsulates both voltage and current readings, simulating the operation conditions that the solar array will encounter. Ultimately, this meticulous approach to inspection and testing safeguards the long-term performance and safety of the solar energy system.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SOLAR COPPER JOINTS ARE AVAILABLE?

Solar copper joints come in various types designed for specific applications within the solar energy sector. The most common types include compression joints, soldered joints, and crimped joints. Compression joints utilize mechanical pressure to hold two copper pieces together, making them easy to install without requiring heat. Conversely, soldered joints involve melting solder to join copper surfaces, providing a strong and conductive bond. Crimped joints are created by deforming a metal sleeve around the copper wires, ensuring a tight connection. Each joint type has its advantages and ideal usage scenarios, which should be assessed based on individual project requirements and site conditions.

HOW DO I MAINTAIN SOLAR COPPER JOINTS AFTER INSTALLATION?

Maintenance of solar copper joints is vital to ensure long-lasting performance. Regular inspections should be scheduled to identify any signs of wear, corrosion, or oxide formation. Cleaning is equally essential; using a soft cloth or appropriate cleaner can help remove dirt and contaminants. If corrosion is detected, immediate action is necessary, such as resealing or replacing the affected joints. Furthermore, ensuring that connections remain tight and free from excessive mechanical stress will enhance longevity. Emphasizing proactive maintenance practices will protect the investment in solar technology and optimize energy output.

CAN I INSTALL SOLAR COPPER JOINTS MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

The decision to install solar copper joints independently or hire a professional hinges on several factors, notably skill level, experience, and the complexity of the solar system. For those with basic electrical knowledge and soldering experience, performing the installation might be feasible. However, complications in larger systems or specific local regulations regarding electrical installations may warrant professional assistance. Engaging a certified installer also brings the benefit of expertise and adherence to safety standards, ultimately ensuring a correctly installed system that minimizes future risks. Therefore, evaluating personal capabilities against project requirements is crucial in making this decision.

Utilizing appropriate materials in the installation of solar copper joints holds significant importance for the performance and efficiency of solar systems. Preparing the workspace meticulously cannot be overstated, as it sets the tone for the entire installation process. Mastering proper soldering techniques ensures robust connections vital for system safety and longevity. Lastly, stringent inspection and testing phases are essential in confirming that all joints meet performance standards. The overall process demands a profound level of diligence and expertise, which contributes significantly to the successful operation of solar energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-copper-joints/