To install solar antifreeze pipe, one needs to undertake specific procedures ensuring effective operation and longevity. 1. Understand the purpose of antifreeze in solar heating systems, 2. Gather necessary tools and materials, 3. Ensure proper pipe insulation and layout, 4. Follow manufacturer recommendations for installation. Each of these factors is critical for achieving optimal efficiency and preventing damage in various weather conditions. For instance, antifreeze plays a crucial role in maintaining fluid temperature within the solar system, protecting against freezing and ensuring uninterrupted functionality during colder months. Identifying suitable materials, including high-quality glycol-based solutions, and understanding their compatibility with the plumbing system are also paramount to guarantee a successful installation and operation.

1. UNDERSTANDING SOLAR ANTIFREEZE SYSTEMS

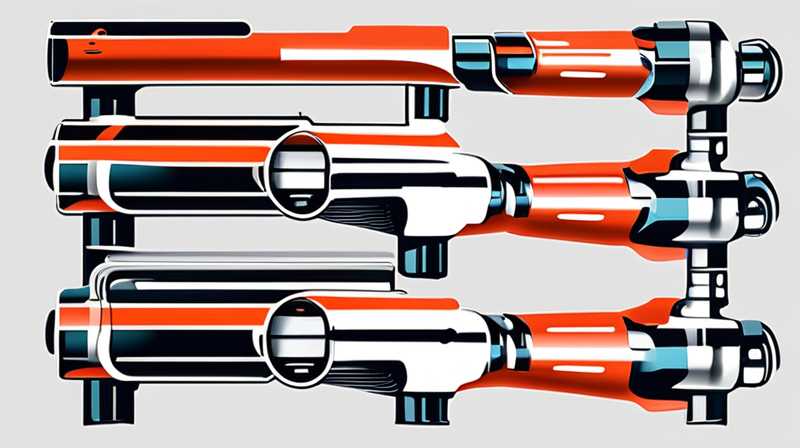

The solar heating systems that employ antifreeze solutions are designed to absorb energy from sunlight to heat water or air. These systems primarily consist of solar collectors, pipes, pumps, and a storage tank. The inclusion of antifreeze is essential, especially in regions where temperatures can drop significantly. Antifreeze solutions prevent the water within the pipes from freezing, which can cause ruptures and reduce the efficiency and lifespan of the system.

On a microscopic level, antifreeze has properties that lower the freezing point of water. Common antifreeze solutions used include propylene glycol and ethylene glycol, both of which serve different applications and require careful handling. Selecting the right antifreeze based on the climate and the specific needs of the solar system is crucial. Furthermore, understanding the thermal properties of these antifreezes can assist in determining the most efficient mix for reducing freeze risk while optimizing heat transfer characteristics.

2. TOOLS AND MATERIALS REQUIRED

Before embarking on the installation of solar antifreeze pipes, one must be thoroughly equipped. Essential tools include pipe cutters, wrenches, thread seal tape, and a drill for securing mounts. Additionally, having access to essential materials such as high-quality solar piping, fittings, and the selected antifreeze solution is imperative. Understanding the specifications of each component helps in reducing installation errors, which can lead to costly repairs and maintenance in the future.

Adequate safety gear should also be part of the preparatory phase, including gloves and safety goggles. When handling antifreeze, it is vital to adhere to safety protocols to prevent any adverse reactions. Proper storage of materials away from sunlight and extremes of temperature helps maintain their integrity. Having a checklist prepared before starting the installation ensures that all essential items are within reach, which facilitates a smoother and more efficient installation process.

3. PROPER INSULATION AND LAYOUT OF PIPES

Installing antifreeze pipes requires attention to detail, particularly regarding insulation and layout. Proper insulation of pipes prevents heat loss and maintains fluid temperature, which is critical for system efficiency. Insulation materials, such as foam or fiberglass, should be used generously in areas likely to experience extreme temperatures.

In addition to insulation, the layout of the pipes should facilitate the efficient flow of antifreeze. Ensuring minimal bends in the piping reduces potential blockages and pressure drops, which can adversely affect system performance. The correct slope of the pipes directs the flow smoothly, preventing the accumulation of gases or condensation, which can hinder efficiency. Generally, following manufacturer guidelines regarding layout can save significant time and resources in the long run.

4. INSTALLATION PROCEDURE

Installing the solar antifreeze pipes involves several essential steps to ensure a seamless workflow and optimal functionality. Firstly, assess the location for the solar collectors and mark the pathway where the pipes will be installed. Ensure that the area receives maximum sunlight exposure throughout the day.

Upon determining the layout, connect the pipes according to the system design. Start by cutting the pipes to appropriate lengths and using fittings to connect multiple sections securely. The application of thread seal tape on joints is essential for preventing leaks, enhancing the overall integrity of the system. Once the connections are secured, clamp or mount the pipes to prevent movement or strain. It is advisable to allow adequate time for the antifreeze mix to circulate and test the system’s efficiency before finalizing the installation.

5. REGULAR MAINTENANCE AND CHECKUP

Maintenance of the solar antifreeze system is crucial for ensuring long-term functionality. Regularly check the antifreeze levels and quality; over time, glycol can degrade. Flush and replace the antifreeze solution every few years or according to manufacturer recommendations.

In addition to antifreeze, inspecting the entire system for leaks or pressure drops is essential. Visually reviewing the insulation for wear or damage ensures that the pipes remain protected from external factors such as temperature fluctuations and UV exposure. Scheduling regular maintenance checks can preemptively address potential issues, saving time and resources in the future while providing peace of mind regarding the system’s reliability.

QUESTIONS REGARDING SOLAR ANTIFREEZE PIPE INSTALLATION

WHAT TYPE OF ANTIFREEZE IS BEST FOR SOLAR PIPES?

When it comes to selecting antifreeze, propylene glycol is often preferred due to its non-toxic properties, making it safer for residential systems. This option is not only effective in lowering the freezing point of water but also offers excellent heat transfer capabilities. Ethylene glycol, while more cost-effective, poses health risks if leaks occur into potable water systems, thus requiring careful handling and consideration. It’s vital to consider the local climate when choosing the right mix, as some areas experience extreme temperature variations. Ultimately, it’s advisable to consult with professionals to determine the most suitable antifreeze solution for specific installations while considering local regulations regarding the use of certain chemicals in residential systems.

HOW OFTEN SHOULD SOLAR ANTIFREEZE BE CHANGED?

Regular intervals for changing solar antifreeze can vary depending on the product and environmental variables. A general guideline suggests checking antifreeze levels and quality at least once a year and replacing it every 3 to 5 years. During these checks, inspect for signs of degradation, such as a change in color or viscosity, which indicates that the antifreeze may no longer provide efficient protection against freezing and corrosion. Testing kits can measure the effectiveness of the antifreeze, including its freezing point and pH levels. Following manufacturer recommendations and specific check-up cycles can ensure that the solar heating system maintains optimal performance without unexpected downtime.

IS PROFESSIONAL ASSISTANCE NECESSARY FOR INSTALLATION?

While DIY installation is feasible for those with adequate technical knowledge, professional assistance is often recommended for several reasons. Expert installers bring experience, ensuring adherence to all relevant codes and regulations that govern solar heating systems. Potential pitfalls that a novice might overlook, such as improper pipe sizing or layout errors, can lead to significant inefficiencies. Additionally, professionals guarantee that the specific needs of the site are met, optimizing spatial arrangement and material selection. Ultimately, engaging professional help may also come with future maintenance agreements, providing further assurance of performance reliability over the years.

The installation of solar antifreeze pipes is an intricate process that requires careful consideration and adherence to specific protocols. Beginning with a thorough understanding of antifreeze properties and the tools required sets the stage for success. Proper insulation and layout play equally crucial roles in promoting efficiency and preventing potential system failures. Each stage of the installation must be meticulously executed, taking into account the importance of connections, materials used, and manufacturer’s instructions. Furthermore, scheduled maintenance checks safeguard the integrity and performance of the system over time. By focusing on these factors, homeowners can ensure that their solar heating systems operate at peak efficiency, providing both comfort and energy savings. Engaging with professionals during installation and maintenance enhances both functionality and longevity, thereby securing an investment that yields sustainable benefits for years to come. The significant advantages of utilizing solar antifreeze technology underscore the potential for environmentally friendly energy consumption while maximizing resource efficiency; thus, investing in a proper installation guarantees peace of mind in the reliability and performance of the solar heating system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-antifreeze-pipe/