How to install solar aluminum plastic tube

1. Solar aluminum plastic tubes are essential components in solar heating systems, featuring several key characteristics: 1, They enhance efficiency through excellent thermal conductivity, 2, They are lightweight and easy to handle, 3, Their durability ensures a long lifespan, 4, They contribute to cost-effectiveness in solar energy systems. The importance of solar aluminum plastic tubes cannot be overlooked, as they play a crucial role in transferring heat from solar collectors to thermal storage tanks effectively. When installing these tubes, proper measures and techniques should be followed to ensure optimal performance and long-term functionality. Among those, careful handling during installation, appropriate connections, and ensuring tight seals to prevent leaks warrant special attention.

1. UNDERSTANDING SOLAR ALUMINUM PLASTIC TUBES

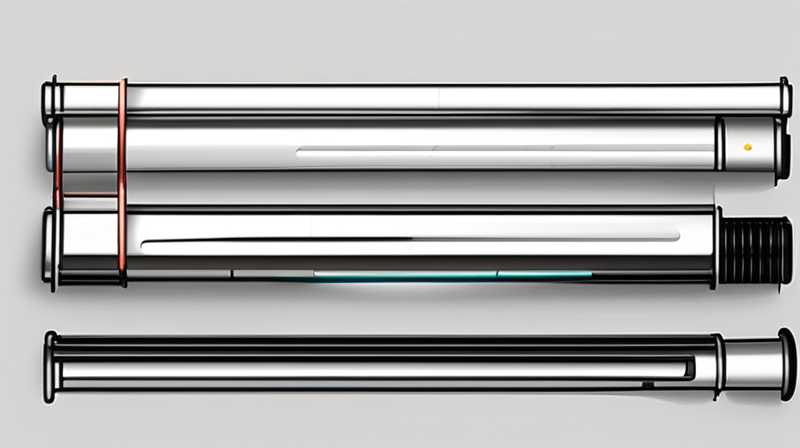

The solar aluminum plastic tube is a specialized component designed primarily for solar heating applications. Composed of a combination of aluminum and plastic, these tubes are engineered to maximize heat transfer while maintaining necessary structural integrity. An understanding of how these tubes work is crucial for their effective installation. The aluminum layer serves to conduct heat rapidly, while the plastic exterior facilitates easy installation and prevents corrosion.

Moreover, the selection of these tubes greatly impacts the overall solar system’s efficiency. Higher quality materials can withstand extreme temperatures while providing excellent insulation. Consequently, installers should evaluate their options and select the best suited for their specific conditions. A thorough understanding of the purpose and functionality of these tubes is crucial before proceeding with installation, as it sets the foundation for effective implementation.

2. PRE-INSTALLATION CONSIDERATIONS

When approaching the installation of solar aluminum plastic tubes, several preliminary aspects should be addressed. A comprehensive assessment of the installation site is vital. This involves evaluating sunlight exposure, potential shading from nearby structures, and the orientation of the solar collectors. The goal should be to achieve maximum solar gain; therefore, correct positioning is essential to the overall effectiveness of the system.

Furthermore, the tools and materials needed for the installation process should be gathered in advance. Adequate measuring tools, cutting tools, and necessary fittings must be prepared. Ensuring that all items are compatible with aluminum plastic tubes is critical to prevent any delays or complications during the installation. Ensuring a smooth installation process requires meticulous planning and preparation, along with an understanding of safety precautions, as working with tools and materials may entail potential hazards.

3. STEP-BY-STEP INSTALLATION PROCESS

The installation of solar aluminum plastic tubes is methodical and requires careful execution of each phase. The first important task involves cutting the tubes to the correct lengths required for the solar heating system. Precision in measurement is essential; too long or too short connections can lead to efficiency losses and difficulties during assembly.

Once the tubes have been appropriately cut, the next step is to connect them properly to the solar collectors. Adhere to manufacturer guidelines strictly, as each system may have unique requirements according to its design. The connections must be secure and well-sealed to prevent leaks, which could impede the system’s overall efficiency.

After the primary connections are in place, the tubes must be attached securely to the structure, minimizing any movement that could cause stress or damage during operation. Proper mounting hardware should be utilized, ensuring that the installations not only support the weight of the tubing but also accommodate any thermal expansion or contraction that might occur with temperature fluctuations.

4. TESTING AND ADJUSTMENTS

Following the completion of the installation, performance testing is a crucial subsequent step. This involves checking all connections for leaks and ensuring that each tube functions as intended within the system. A simple pressure test can help ascertain whether the connections remain watertight under operational conditions.

If any leaks or weaknesses are discovered, immediate adjustments should be made. Additionally, checking the system’s flow rates and temperatures allows for fine-tuning adjustments to optimize performance. These tests help ensure that the solar system operates at its maximum efficiency from the onset, leading to better overall energy savings.

Organizing regular maintenance checks post-installation also plays a critical role in the longevity of the system. Keeping a scheduled routine for evaluating the connections, performance, and condition of the tubes is essential for identifying potential issues before they escalate. Such proactive measures can significantly enhance the durability and effectiveness of the solar heating system.

5. MAINTENANCE OF SOLAR ALUMINUM PLASTIC TUBES

Ongoing care and maintenance of solar aluminum plastic tubes require diligence. Regular inspections are recommended to assess the condition of the tubes and their fittings. Any signs of wear, corrosion, or damage should be addressed promptly to minimize any negative impacts on efficiency.

Proper cleaning methods should be employed during maintenance routines. Dirt, dust, or debris can accumulate on the surface, reducing solar absorption and thereby diminishing overall system effectiveness. Utilizing gentle cleaning techniques will ensure that the tubes maintain optimal performance without risking damage.

Furthermore, the inspection of all connections is vital to check heat and pressure tolerances. Any misalignments or loose connections should be repaired or replaced to maintain system integrity. Emphasizing routine maintenance extends the lifespan of the system while ensuring that the energy output remains at desirable levels.

6. SAFETY MEASURES TO IMPLEMENT

While embarking on the installation journey of solar aluminum plastic tubes, implementing safety measures is non-negotiable. Working with tools and possibly elevated structures can pose risks; therefore, using appropriate personal protective equipment is essential. Gloves, safety glasses, and sturdy footwear should be standard attire during any installation process.

Furthermore, if working at heights, using a sturdy ladder or scaffold is critical for maintaining safety. Proper training in lifting techniques and the handling of tools minimizes the likelihood of injuries during installation. It is prudent to adhere to local building codes and regulations, ensuring that all safety guidelines are followed effectively.

Lastly, securing installation areas to prevent unauthorized access or accidents during the process will ensure a safer work environment. Highlighting the significance of safety measures not only protects the individuals undertaking the project but also ensures that the installation remains unencumbered by avoidable incidents.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE ADVANTAGES OF USING SOLAR ALUMINUM PLASTIC TUBES?

Solar aluminum plastic tubes offer a plethora of advantages. To begin with, they possess superior thermal conductivity due to the aluminum layer, which facilitates effective heat transfer from solar collectors to the thermal storage systems. This leads to improved energy efficiency and lower operational costs in solar heating applications.

In addition, their lightweight nature simplifies handling and installation. This reduction in weight means less structural support is needed for installation fixtures, thereby lowering overall labor and material costs. Moreover, these tubes exhibit excellent resistance to environmental factors such as UV radiation and oxidation, ensuring longevity and durability in challenging conditions.

The ability of aluminum plastic tubes to maintain insulation properties is another significant benefit. Enhanced insulation reduces heat loss during transfer, further contributing to the system’s overall efficiency. As a result, their combination of efficiency, durability, and installation ease makes them an ideal choice for solar heating installations.

HOW DO I MAINTAIN SOLAR ALUMINUM PLASTIC TUBES?

Effective maintenance of solar aluminum plastic tubes involves several crucial steps. Firstly, regular inspections should be scheduled to assess the physical condition of the tubes and check for signs of wear and tear. Any damage, such as cracks or corrosion, needs immediate attention to prevent further deterioration of the system.

Secondly, cleaning practices should be employed periodically. Accumulations of dirt, grime, and debris can hinder the tubes’ efficiency by limiting their ability to absorb sunlight. Using soft cloths and non-abrasive cleaners is recommended to preserve the integrity of the tube’s surfaces.

Additionally, monitoring the connections and securing fittings is vital for maintaining optimal performance. Loose connections can lead to leaks and inefficiencies in the solar system. Regularly tightening and verifying connections ensures that the system operates safely and effectively. Lastly, keeping records of maintenance activities and any issues found can help in tracking the performance and longevity of the solar aluminum plastic tubes over time.

CAN I INSTALL SOLAR ALUMINUM PLASTIC TUBES MYSELF?

Yes, it is feasible for an individual to undertake the installation of solar aluminum plastic tubes independently. However, it is vital to have a comprehensive understanding of the installation process, tools, and safety measures involved. Prior research and familiarity with the components and technical specifications of the solar system will aid in ensuring a successful installation.

If the individual possesses good mechanical skills and can follow guidelines or instructions available from manufacturers, the task becomes more manageable. Nonetheless, awareness of local building codes and regulations is paramount, as compliance may dictate certain procedural requirements during installation.

For those lacking confidence or skills, professional assistance is always an accessible option. Ultimately, whether opting for a DIY route or seeking professional help, thorough preparation and knowledge are essential for a successful installation. The quality of the installation significantly influences the performance and longevity of the solar heating system.

In summary, the installation of solar aluminum plastic tubes embodies critical processes that contribute to maximizing solar energy systems’ efficiency. Rigorous pre-installation planning, meticulous execution of each phase, effective maintenance strategies, and adherence to safety protocols guarantee successful deployment. The profound advantages these tubes present, such as enhanced thermal transfer and durability, further solidify their value in solar applications. Building a solid understanding of how to effectively install, maintain, and utilize solar aluminum plastic tubes will ultimately contribute to the overall success of solar energy projects, leading to sustainable energy solutions and significant long-term benefits. An ongoing commitment to safety, in addition to proactive maintenance, ensures the installation’s integrity and performance over the years, paving the way for a cleaner, greener future in energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-aluminum-plastic-tube/