How to install electric solar bracket

1. Proper assessment of the mounting location is essential, 2. Gathering the necessary tools and materials is crucial, 3. Securely attaching the brackets is vital, 4. Testing the installation ensures functionality. Installation of electric solar brackets involves meticulous planning and execution to guarantee optimal performance and durability of solar panels.

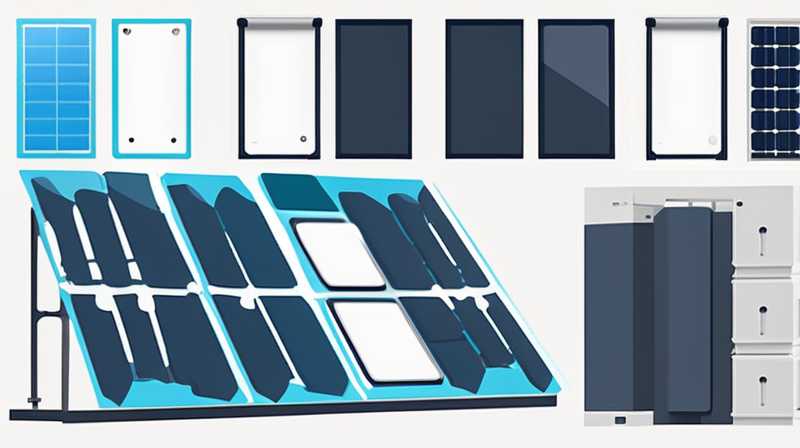

1. OVERVIEW OF SOLAR BRACKETS

In contemporary energy solutions, electric solar brackets offer robust support structures designed to secure photovoltaic panels effectively. These components are pivotal, as they directly influence the efficiency, lifespan, and overall performance of solar energy systems. The brackets must withstand environmental challenges, including wind and snow loads, while ensuring proper orientation of the panels for maximum solar gain.

Selecting appropriate brackets hinges on various factors, such as panel dimensions, local climate conditions, and the intended installation surface. Heavy-duty materials like aluminum or galvanized steel are commonplace due to their resistance to corrosion and durability. Additionally, understanding the installation method is crucial, as it can vary depending on whether the brackets are mounted on rooftops, ground structures, or pole systems.

2. IDENTIFYING THE INSTALLATION LOCATION

Determining where to install the solar brackets is an initial priority. A thorough inspection of the site is essential to evaluate the amount of sunlight exposure available throughout the day. Shading from trees, buildings, or other obstructions can significantly reduce energy capture, thereby necessitating a carefully selected installation area free of such hindrances. Ideally, panels should face south (in the Northern Hemisphere) or north (in the Southern Hemisphere) to optimize solar exposure.

It’s also advisable to take into account the orientation and tilt angle of the solar panels. These factors can augment energy absorption, requiring potential adjustments to the bracket installation to ensure that the angle is conducive to optimal energy capture. Furthermore, reviewing local zoning laws and regulations concerning solar installations can prevent future legal complications.

3. GATHERING TOOLS AND MATERIALS

Prior to embarking on bracket installation, compiling all requisite tools and materials is critical for an efficient workflow. The following items are commonly needed: a drill with appropriate drill bits, a level, a measuring tape, wrenches, and mounting hardware such as bolts and brackets specific to solar panels. Ensuring that all tools are in good working order will minimize interruptions during the installation process.

Moreover, evaluating your solar panel kit can yield additional components like mounting rails, which may support the brackets. Reading the manufacturer’s instructions can provide insights into specific requirements or recommendations they may have for the process, ensuring that no critical components are overlooked. Using high-quality materials and accessories is integral to securing the longevity of the installation, avoiding future issues with rust, structural weaknesses, or disintegration of components.

4. MOUNTING THE BRACKETS

With all tools and materials at hand, the next step involves the actual mounting of the electric solar brackets. Begin by marking the positions for the brackets, ensuring they align with the panel’s mounting points. It’s crucial to use a level to ensure accuracy, as uneven brackets can lead to misalignment of solar panels. Once the positions are marked, drill pilot holes in the designated locations, being cautious not to breach necessary waterproofing or barrier elements within a roofing structure.

Next, attach the brackets according to the specifications provided in the installation kit. Utilizing a torque wrench to achieve the manufacturer’s recommended tightness can prevent future loosening or damage to the mounting structure. Each bracket should be securely fixed and double-checked to ensure stability. As with any construction or installation process, following the proper safety protocols is paramount. Wearing protective gear and adhering to safety recommendations will mitigate the risk of accidents.

5. MOUNTING THE PANELS ON THE BRACKETS

After the brackets have been securely installed, it’s time to mount the solar panels themselves. Establish a systematic approach to carefully lift and place each panel onto the brackets. Ensuring that the panels are aligned correctly with the brackets’ mounting points is essential, as misalignment can lead to stress on the panels and a decrease in efficiency.

Use the mounting hardware included with the solar panel kit carefully, ensuring that each screw or bolt is appropriately tightened to maintain a secure hold. Consider using spacers as recommended by the manufacturer to provide necessary ventilation between panels, which can help prevent overheating and inefficiency. After mounting all panels, performing a thorough inspection to confirm correct installation and firm attachment is wise.

6. WIRING AND ELECTRICAL CONNECTIONS

Following the physical installation of the solar panels on brackets, attention must turn to the necessary electrical connections. The wiring process involves connecting the solar panels to an inverter system that converts the generated DC power to usable AC power. Careful attention to wiring techniques is vital to avoid potential electrical hazards. Utilizing connectors specifically designed for solar applications prevents moisture and enhances durability.

Engaging a qualified electrician to assist with wiring can ensure that local electrical codes are adhered to rigorously. This step is paramount, as faulty wiring can lead to inefficient operation or hazardous conditions. Furthermore, installing DC and AC disconnects can facilitate safety and servicing when needed. Always double-check guidelines provided by panel manufacturers to ensure proper integration with inverter systems. Following these steps diligently supports the safety and performance of the entire solar installation.

7. TESTING SYSTEM FUNCTIONALITY

Once the installation procedure is concluded, conducting tests is an indispensable step in the overall process. Verification of the installation’s functionality involves checking all connections and ensuring that panels produce the expected output of electricity. Measurements of voltage and current should be taken using appropriate testing devices to confirm that everything operates as it should. If discrepancies are observed, revisiting connections and adjustments may be necessary.

It’s also advisable to monitor the system over the coming days or weeks to observe performance levels under various conditions. If the system does not perform optimally, diagnosing potential issues, including misalignment or faulty wiring, will be critical. Analyzing performance data can help assess whether the installation meets energy generation expectations and demonstrate the effectiveness of the chosen site and approach.

8. MAINTENANCE OF SOLAR INSTALLATIONS

Upkeep of the solar installation is essential for optimizing performance over time. Regular inspections should include checks on bracket integrity, panel cleanliness, and electrical connections. Dirt, dust, and debris can accumulate and adversely affect the efficiency of solar panels, thereby necessitating cleaning to maximize solar gain. Depending on the environmental conditions, determining the optimal frequency for cleaning is key.

Furthermore, ensuring that trees or other foliage do not grow in ways that cast shadows on the panels is also vital. Any growth that encroaches on the installation site should be managed proactively. Additionally, keeping connections dry and free from corrosion will maximize longevity. Following the initial installation process, maintaining an ongoing schedule for inspections and routine maintenance tasks ensures sustained effectiveness of the solar energy system.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF INSTALLING SOLAR BRACKETS?

Installing solar brackets fundamentally supports the secure attachment of solar panels while enhancing their durability and performance. By providing stability, these brackets help resist strong wind and snow loads, fostering resilience throughout various weather conditions. Additionally, proper installation can optimize the angle and orientation of the solar panels, allowing for improved solar exposure and energy capture.

This leads to increased efficiency and a return on investment over time, making solar energy a more viable option for residential and commercial applications. Moreover, brackets are often designed to facilitate ease of maintenance, enabling users to access panels for cleaning or repairs without hassle. If you factor in the longevity of solar energy systems, investing in quality solar brackets is an economically sound decision that supports sustainable energy solutions.

CAN I INSTALL SOLAR BRACKETS MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

The decision to self-install solar brackets or engage a professional technician hinges on various factors, including personal skill level, installation complexity, and familiarity with electrical systems. For those possessing construction experience and understanding of solar energy systems, a DIY approach may yield satisfactory results. However, it’s imperative to be cognizant of the potential risks, such as improper installation leading to inefficiency or safety hazards.

If an individual feels unsure or lacks experience with such installations, hiring a professional is advisable. Professional installers often bring expertise in adhering to local codes and regulations, which can be particularly beneficial. Additionally, leveraging their skills can ensure that every component is installed correctly. Investing in professional installation can lead to peace of mind concerning safety and system performance, providing significant reassurance for homeowners and businesses alike.

HOW OFTEN SHOULD SOLAR INSTALLATIONS BE MAINTAINED?

Maintenance frequency for solar installations is contingent upon a multitude of variables, including geographical location, environmental conditions, and the surrounding landscape. In areas with higher dust or pollen accumulation, routine cleaning of solar panels is advisable to prevent efficiency loss due to dirt buildup. Likewise, regions that experience heavy rainfall may need less frequent maintenance, as natural precipitation often aids in washing panels.

Routine inspections should occur at least annually, encompassing checks on the structural integrity of mounting brackets, the clarity of solar panels, and the condition of electrical connections. Implementing a schedule of regular monitoring can preemptively identify potential issues, ensuring seamless operations throughout the lifespan of the system. Proactive maintenance not only extends the longevity of installations but also maximizes energy production, ultimately optimizing the investment in solar technology.

CONCLUDING REMARKS

The installation of electric solar brackets encompasses a series of crucial steps that demand careful attention and expertise. Proper assessment of the location, gathering of essential materials, and secure mounting procedures play pivotal roles in guaranteeing an effective and durable setup. By understanding how to navigate these processes, individuals can ensure that their solar installations achieve maximum efficiency and longevity. Undertaking tasks such as wiring and functionality testing further supports the seamless operation of the system, empowering users with sustainable energy solutions. Establishing a routine maintenance schedule not only preserves the functionality of solar installations but enhances their overall performance while safeguarding the investment involved. Ultimately, thorough planning and execution are imperative in facilitating successful solar energy utilization, thereby contributing to more environmentally responsible energy consumption practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-electric-solar-bracket/