1. Installing an aluminum-plastic tube for solar energy requires several critical steps that ensure efficiency and longevity. 2. The process begins with selecting the appropriate aluminum-plastic tube, which must conform to industry standards for solar applications. 3. Next, precise measurements should be taken to determine the length and configuration needed for optimal performance, considering factors such as system layout and energy output goals. 4. Proper installation techniques must then be employed to secure the tubing, minimizing any potential energy losses due to improper fitting or installation mistakes. It’s essential to follow manufacturer guidelines meticulously at every phase to guarantee that the system operates effectively without compromising its structural integrity or performance.

1. UNDERSTANDING ALUMINUM-PLASTIC TUBING

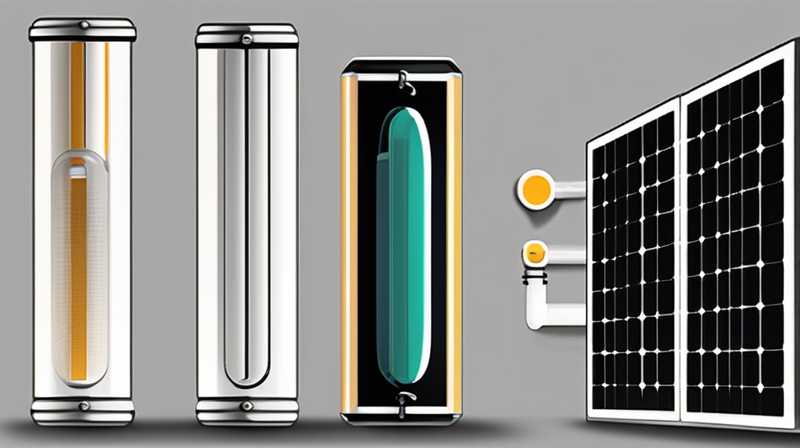

To grasp why aluminum-plastic tubing is immensely favored in solar applications, one must consider its composite nature. Aluminum-plastic tubes combine the lightweight properties of aluminum with the durability of plastic, leading to increased versatility in deployment. This amalgamation not only allows for easier installation but also guarantees resilience against environmental factors.

Moreover, maintaining solar systems with aluminum-plastic tubes becomes significantly simpler than with traditional materials. The resistance of these tubes to corrosion is exceptional, which is paramount in solar applications where exposure to varied climatic conditions is a given. This means that the longevity of the entire solar energy system can be enhanced through the use of this innovative material.

2. SELECTING THE RIGHT TUBING

Choosing the appropriate aluminum-plastic tube for solar panels entails careful consideration of several technical specifications. A significant aspect to focus on includes the pressure ratings of the tubes, which should align with the system’s operational necessities. Utilizing tubes that can withstand maximum pressures without leakage is critical to ensuring the effectiveness of the solar energy conversion process.

The dimensions of the tube also play a pivotal role. It is vital to match the tubing’s diameter with the fittings and connectors used in the solar system to prevent energy losses through gaps or poorly fitted joints. Compatibility with existing components ensures that the overall system performs at its best, maximizing the potential return on investment.

3. TAKING ACCURATE MEASUREMENTS

Before initiating the installation, an accurate assessment of the installation area is crucial. Consider the layout of the solar array, the angle of incidence of sunlight, and any potential obstructions that could impact performance. Each of these factors will have a direct influence on how the aluminum-plastic tubes are positioned and installed.

In this phase, meticulous measurements must be recorded. Evaluate the total length of tubing required and account for any bends or curves that need to be integrated into the design. Utilizing measuring tools such as laser distance meters can enhance precision, allowing for an effective fit that minimizes waste and maximizes efficiency.

4. PREPARING THE INSTALLATION SITE

An optimal installation site contributes significantly to the effective use of aluminum-plastic tubes in solar energy systems. The area should be cleared of any debris or obstacles that might interfere with the installation process. Moreover, checking for existing electrical cables or structural components within the provided space is necessary to avoid unforeseen complications.

Once the site is adequately prepared, the next step includes laying out the tubing plan based on previously taken measurements. This often entails marking the ground to indicate where tubes will be placed and ensuring that paths for laying out the tubes are unobstructed. Keeping the design organized not only streamlines the installation process but can also provide valuable insights during future maintenance.

5. INSTALLATION TECHNIQUES

When beginning the installation of aluminum-plastic tubing for solar energy systems, employing the right techniques is critical. Research and apply proper techniques for securing the tubes to the supporting structure of the solar panels, as this can impact longevity and performance. Ensuring that the tubes are installed tightly will reduce the likelihood of energy losses significantly through friction or improper connections.

A common method includes the use of brackets or clamps to hold the tubing in place securely. This not only aids in stability but can be essential in environments subject to wind or other stresses. Furthermore, consider using heat-shrink connectors for joints to eliminate potential leaks while providing additional insulation against outdoor elements.

6. TESTING THE SYSTEM

Once installation is complete, conducting tests to verify system integrity is mandatory. Pressure testing the entire setup can identify any potential leaks that could impede system efficiency. Employing water, air, or other testing mediums can ensure that joints and fittings are sealed properly.

Monitoring the system’s performance over a span of time is also recommended. Utilizing gauges and data loggers to track energy production or loss during operation will provide valuable insight into system efficiency. If irregularities are noted, it could indicate problems with the tubing installation that may require adjustments.

7. MAINTAINING THE SYSTEM

Regular maintenance will significantly extend the lifecycle of the aluminum-plastic tubes and, subsequently, the solar energy system itself. Inspection of the tubing should be conducted periodically to ascertain its condition and detect any potential wear. In particular, look for signs of corrosion or stress that may have been exacerbated by environmental factors.

Additionally, employing a routine cleaning regime can enhance performance significantly. Debris accumulation can block sunlight or cause heat accumulation, reducing energy production. Utilizing appropriate methods and non-corrosive cleaning agents will ensure that the tubes remain effective over time.

8. COMMON CHALLENGES IN INSTALLATION

Despite the straightforward nature of the installation process, several challenges can arise that require prompt resolution. One common issue is the potential for tubing to kink during installation, which could compromise functionality. Utilizing proper handling techniques and support systems can mitigate this risk significantly.

Another challenge can involve environmental factors, such as weather conditions during installation. If improper conditions exist (like rain or high winds), it may render the installation ineffective, leading to unnecessary delays. Awareness of weather forecasts and planning installations during optimal conditions can circumvent these obstacles entirely.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF ALUMINUM-PLASTIC TUBING IS BEST FOR SOLAR APPLICATIONS?

Selecting the right type of aluminum-plastic tubing for solar applications hinges on several criteria. First, it is essential to ensure compatibility with specific solar panels and systems, considering factors like pressure ratings and diameter. Tubes designed specifically for solar energy must withstand temperature fluctuations, UV radiation, and other environmental stresses without degrading or deforming. Conducting thorough research on various manufacturers and their specifications will ensure you select the best possible option for your installation.

It’s advisable to consult with professionals or experts in solar energy systems when in doubt about which tubing is suitable for your needs. By assessing the overall solar setup, including panel orientation and ambient conditions, you can make more informed decisions that will enhance efficiency. Additionally, investing in high-quality tubing will contribute to the longevity of the entire solar system, ultimately saving costs in repair and replacement.

HOW DO I MAINTAIN ALUMINUM-PLASTIC TUBES IN MY SOLAR ENERGY SYSTEM?

Maintenance of aluminum-plastic tubes within solar energy systems involves regular inspections and cleaning to ensure optimal performance. Begin by visually examining the tubes for any signs of wear, such as stress marks, corrosion, or kinks, which can occur over prolonged exposure to environmental elements. Addressing these issues promptly will minimize downtime and potential damage to the overall system.

Moreover, conducting a thorough cleaning process to eliminate dirt or debris build-up will enhance the efficiency of energy transfers. Utilizing appropriate cleaning agents that do not damage the tube’s surface is essential. In cases where extensive repairs are necessary, consider consulting professionals for guidance on replacing damaged sections without disrupting the entire system. Regular maintenance ensures a sustainable, long-lasting solar installation.

WHAT SHOULD I DO IF THERE’S A LEAK IN MY ALUMINUM-PLASTIC TUBING?

If a leak is detected in the aluminum-plastic tubing, immediate action is crucial to prevent further complications within the solar energy system. Firstly, isolate the affected section of the tubing by shutting off power to the system as a precautionary measure. Inspect the area around the leak carefully, identifying the extent of the damage and if it is a result of wear or poor installation.

Depending on the severity of the leak, you may need to repair or replace the affected tubing section. For minor leaks, a sealing tape or adhesive specifically designed for plastic can provide a temporary solution. However, replacing the damaged section may be necessary for a long-term fix, ensuring that the tubing maintains its integrity and functions efficiently. Calling a certified technician might be advisable if you are unsure about the repairs, as they can offer insights based on experience and expertise.

In summary, embarking on the journey of installing aluminum-plastic tubing for solar energy systems necessitates careful planning and execution. It starts with a thorough understanding of the material and the selection of the right tubing followed by accurate measurements of the installation area. Attention to detail during installation ensures an efficient solar energy system that can withstand environmental pressures. Periodic maintenance and awareness of common challenges will facilitate the longevity and performance of the entire solar setup. Ultimately, a systematic approach to installation and upkeep transforms these components into reliable assets, propelling the forward momentum in renewable energy.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-aluminum-plastic-tube-for-solar-energy-2/