Installation of a wall-mounted solar angle valve involves several crucial steps, which can be summarized as follows: 1. Preparation is essential. Before installation, gather all necessary tools and materials, ensuring the area is clean and accessible. 2. Select the location with care. It is vital to choose an appropriate position for the valve to optimize both accessibility and functionality. 3. Follow precise instructions. Adhering to specific manufacturer’s guidelines guarantees a safe and efficient installation. 4. Test for leaks after installation. Once the valve is fitted, conduct thorough testing to identify any potential leaks that may compromise the system’s integrity. Among these points, preparation proves to be crucial, as having the right tools and working in a clean area can significantly influence the installation’s success.

1. PREPARATION FOR INSTALLATION

Successful installation of a wall-mounted solar angle valve begins with comprehensive preparation. This phase includes gathering all necessary tools and materials that ensure the process goes smoothly. Essential tools include a wrench, screwdriver, Teflon tape, and potentially a drill, depending on wall composition. Ensure that the valve you select is compatible with your existing solar system, which often involves checking specifications from the manufacturer or consulting with a professional.

Additionally, the surrounding area must be examined for cleanliness and accessibility. An organized workspace not only enhances productivity but also minimizes the risk of accidents. Having the right tools on hand avoids the frustration of interrupting the installation to acquire additional materials. Preparing this way lays a solid foundation for a successful installation and reduces the likelihood of issues at later stages of the process.

2. CHOOSING THE RIGHT LOCATION

Selecting the correct location for mounting a solar angle valve is imperative for both functionality and accessibility. The first consideration is the proximity to existing solar plumbing to minimize the necessity for extensive piping adjustments. Ideally, the valve should be placed in a spot that allows for easy operation and maintenance. Ensuring that the area is unimpeded by other fixtures or structures can facilitate a more straightforward operation of the valve as well.

Furthermore, consideration of natural elements such as sunlight exposure and potential weather-related impacts is critical. The location must offer adequate protection from harsh weather conditions, particularly if the angle valve is situated outdoors. In some instances, installing the valve in a shaded area can prevent overheating and prolong its lifespan significantly, enhancing system efficiency over time. Ultimately, a careful selection of the location is integral to the long-term efficacy of the solar setup.

3. FOLLOWING INSTRUCTIONS

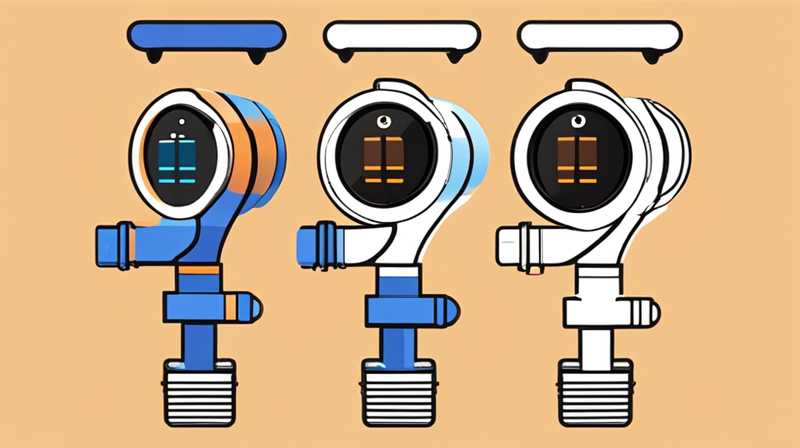

Adherence to precise manufacturer instructions cannot be overstated when installing a wall-mounted solar angle valve. Installation guides typically provide step-by-step procedures tailored specifically for the product, which helps in avoiding common pitfalls. These manuals often include information about the valve components, necessary pre-installation checks, and specific torque requirements for fittings. Following these guidelines helps to avoid damage to either the valve or the connected solar system.

Moreover, if you encounter uncertainties while dissecting the instructions, consulting a professional can mitigate risks of improper installations. Continuous reference to the instructions ensures precision in alignment and secure fastening. Besides manufacturer instructions, online tutorials and videos can serve as supplementary resources that provide visual demonstrations of the installation processes. Ensuring a thorough understanding of all procedural elements is vital for the successful installation of the solar angle valve.

4. INSTALLING THE VALVE

With the preparations completed and the installation location determined, it is time to begin the physical installation of the wall-mounted solar angle valve. Begin by marking the spots on the wall where the valve will be mounted. These markings should correspond accurately to the valve’s attachment points. Utilizing a level during this step ensures correct alignment and functionality once the installation is complete.

Next, pre-drilling holes at the marked locations may be necessary, depending on the wall type. If you are dealing with concrete or brick walls, specific masonry bits and anchors are needed for effective installation. In contrast, drywall may suffice with simple wall anchors or screws. Once the holes are made, securely fasten the valve using the appropriate fasteners while ensuring that it sits flush against the wall. Pay attention to gaskets or O-rings, which should be replaced or checked during this installation phase to prevent leaks.

5. CONNECTING THE PIPING

Following the initial valve installation, connecting the piping is a crucial next step. Ensure that all pipes leading to and from the valve are clean and free from debris. This prevents any blockages that could impair functionality. Here, using Teflon tape on the threads of the pipes promotes a watertight seal. Carefully thread the pipes into the valve, employing either hand-tightening or wrench, ensuring they do not cross-thread or overtighten.

During this stage, maintaining alignment is essential. Check each joint to confirm that they are properly aligned and not putting undue stress on the valve itself. A misaligned connection can lead to future leaks and requires significant effort to correct. After establishing proper connections, double-check all attachments and fittings before considering the installation complete.

6. TESTING FOR LEAKS

Once installation has reached the conclusion, immediately conducting a thorough testing for leaks is paramount. Turn on the water flow to the system slowly while observing all connected fittings and the valve itself. If any water seeps out, it indicates a poor connection that requires addressing. Tightening the fittings may resolve minor leaks; however, if problems persist, disassembling and inspecting threaded connections may be necessary.

Utilizing a pressure gauge to monitor the system’s pressure can also highlight issues. Abnormalities in pressure may signal leaks or other complications in the system. This phase should not be rushed; taking time to thoroughly inspect the setup will save time and effort in the long run by preventing future maintenance burdens. Proper water pressure stabilization ensures the system operates as designed, confirming the effectiveness of the installation.

7. MAINTENANCE TIPS

Long-term efficacy of a wall-mounted solar angle valve hinges significantly on routine maintenance. Checking for leaks periodically is crucial, particularly in the seasonal shifts when the temperature fluctuates. Inspecting every fitting and connection for signs of wear or damage can prevent bigger issues down the line. If any wear is spotted, replacing the affected component immediately is advisable.

Similarly, clear any debris around the valve, as this could create future obstructions or operational difficulties. Keeping the area clean not only promotes longevity but also ensures accessibility to the valve should repairs or adjustments be needed. Regular annual maintenance checks alongside daily inspections can preserve the system’s integrity, allowing for efficient and dependable performance for years ahead.

8. EXPANSION AND ENHANCEMENTS

Upon successful installation and maintenance of a wall-mounted solar angle valve, consider potential enhancements that can further improve system performance. Integration of additional solar components such as expansion tanks or solar controllers enhances overall energy efficiency and provides improved heat management within the system.

Furthermore, upgrading to smart technology can enable remote monitoring and operation, providing real-time insights into performance levels. Such enhancements can significantly optimize the overall energy yield while offering greater control over the solar system’s operation, enabling comprehensive oversight and adjustments as needed. This level of management ensures optimal performance through fluctuating environmental conditions, effectively extending service life while maximizing utility.

COMMON QUESTIONS

WHAT TOOLS ARE NEEDED FOR INSTALLATION?

During the installation of a wall-mounted solar angle valve, having the right tools is crucial for a successful outcome. Essential items include a wrench, which assists in tightening and loosening fittings, a screwdriver for securing any screws, and Teflon tape to ensure leak-proof connections. Additionally, a level can be helpful to guarantee that the valve is mounted correctly. Depending on your specific wall type, you might need a drill and appropriate bits, especially if the wall is concrete or brick. Ensure that you’re equipped with any additional materials suggested by the manufacturer for their particular valve model to streamline the installation process.

Additionally, verifying compatibility between your tools and the valve is vital, as using the wrong size could lead to stripping threads or damage. A protractor may also be necessary if the angle between connections requires precision cuts. Overall, having all required tools prepared beforehand can significantly enhance the installation experience.

HOW TO TROUBLESHOOT LEAKS AFTER INSTALLATION?

Post-installation, discovering leaks can lead to frustration; however, troubleshooting is essential to maintaining system integrity. First, identify the source of the leak by examining all connections and the valve itself. A visual inspection often reveals whether fittings are loose or improperly sealed. If the leak is minor, simply tightening the fittings may suffice. However, for persistent issues, it might be necessary to disassemble and replace any damaged components, such as O-rings or gaskets.

To avoid future leaks, routinely scheduled inspections can aid in early detection of wear or damage. Additionally, consider the temperature fluctuations within the environment, as they can cause materials to expand or contract, potentially weakening seals. Implementing preventive measures ensures the integrity of the system, keeping it operational and reliable over time.

HOW CAN I IMPROVE THE LONGEVITY OF THE VALVE?

Enhancing the longevity of a wall-mounted solar angle valve revolves around proactive maintenance practices. Start with regular inspections to catch any early signs of wear, such as corrosion or buildup of debris. Clean the area surrounding the valve regularly, and ensure that all connections remain secure. Elevating awareness about seasonal weather changes is also beneficial; extreme temperatures can influence the materials used in the valve’s construction.

Additionally, consider employing protective measures, such as insulation for pipes in extreme weather climates, to avoid damage. Installing quality components from the outset plus routinely monitoring performance will contribute to longevity while ensuring reliable operation throughout the year. Establishing a preventive maintenance routine can significantly extend the lifespan of the valve and its surrounding infrastructure.

Installation of a wall-mounted solar angle valve represents both a technical task and an opportunity for enhancing energy efficiency. Preparing adequately, choosing a favorable location, following manufacturer instructions, and maintaining the system are all pivotal components of a successful venture. Recognizing that this process requires careful execution further emphasizes the need for thorough understanding and preparation before commencing installation. Therefore, an ultimate balance of functionality and accessibility will yield optimal results, and ongoing diligence with inspections and maintenance will bolster operational durability. This process, when executed properly, not only improves the efficiency of a solar setup but also supports sustainable energy practices that can benefit both the user and the environment for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-a-wall-mounted-solar-angle-valve/