To install a solar overflow valve, first prepare the materials and tools needed for the installation, including the valve itself, appropriate fittings, sealant, tools for cutting and securing pipes, and safety gear. Secondly, ensure you have a clear understanding of the system’s layout and identify the location for valve placement, usually at the highest point of the solar circulation system. Thirdly, turn off the system and drain any fluids to prevent spills or leaks. Fourthly, follow the manufacturer’s instructions for the valve, which often includes cutting existing pipes and installing the valve with proper fittings. Finally, check all connections for leaks and ensure the system operates correctly after installation.

1. ESSENTIAL TOOLS AND MATERIALS

Before embarking on the installation of a solar overflow valve, having the right tools and materials is paramount. The essential items include:

- Solar overflow valve: This is the primary component that primarily directs excess water away.

- Pipe fittings: Various sizes may be necessary depending on the existing system configuration.

- Sealant or thread tape: To ensure a leak-proof installation at all connections.

In addition to these, tools such as pipe cutters, wrenches, screwdrivers, and safety goggles will be important. Proper preparation cannot be overlooked, as it significantly enhances efficiency and safety during the installation process. Each piece plays a critical role, and ensuring all materials are available beforehand promotes a smoother workflow.

Moreover, obtaining an installation manual from the manufacturer ensures adherence to specific guidelines and best practices, essential for warranty validation and optimal performance. Moreover, consider including a pipe cleaning tool to aid in preparing existing pipes by removing any rust, debris, or old sealant that may interfere with a smooth installation.

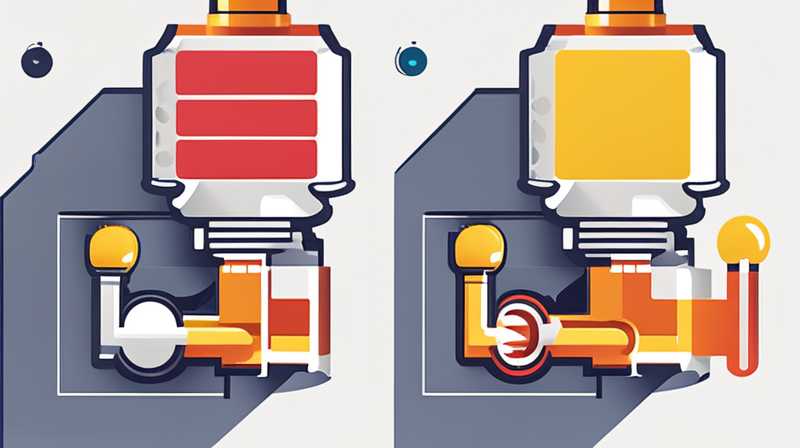

2. UNDERSTANDING THE WORKING MECHANISM

One must understand the mechanism of a solar overflow valve to install it effectively. At its core, this valve is designed to manage excess fluid in a solar heating system. When the system operates beyond its capacity, the overflow valve opens to prevent damage from overpressure situations.

This mechanism generally works on the principle of pressure differentials. When the internal pressure reaches a certain threshold indicating that the storage tank or pipes are full, the overflow valve activates, diverting excess fluid. This action helps to maintain the efficiency and longevity of the solar heating system by ensuring that pressure levels remain within specified limits, preventing the risk of bursts or leaks in the plumbing.

Understanding this basic principle aids in determining where the valve should be installed. Proper placement typically involves locating the highest point in the solar panel network, helping to ensure that any overflow is effectively directed away from the panels, thus protecting the entire system against potential damage.

3. LOCATING THE INSTALLATION POINT

Determining the proper installation point for the solar overflow valve is critical. Generally, the best location is at the highest point in the solar system to allow effects against gravity and ensure effective drainage. A thorough examination of the existing layout can reveal suitable locations.

When examining your system, consider areas adjacent to the storage tank or points where fluid naturally collects. By selecting such spots, you can facilitate a more effective overflow discharge and minimize the potential for backflow. To assist this process, sketch a layout of your system, marking potential locations for the valve, as this will assist significantly in visualizing flow paths.

Additionally, during this assessment phase, ensure that the installation point will not obstruct existing components or maintenance access. It is important to maintain clear access points for future inspections or repairs. This careful consideration at the outset will pay dividends by simplifying any future troubleshooting operations.

4. DRAINING THE SYSTEM AND SAFETY MEASURES

Before commencing the physical installation of the solar overflow valve, safety measures and draining the system are imperative. Ensure the entire solar system is turned off. This step reduces the likelihood of accidents and injuries during installation. Even seemingly minor fluid leaks can pose risks to safety and property.

Next, locate any drain valves associated with your system, and use these to evacuate water from the pipes. This step may require you to place a bucket or hose beneath the draining points for fluid collection. Allow sufficient time for water to fully empty from the storage tank and all pipes to ensure a dry working environment.

Beyond draining operations, wearing safety gear, such as gloves and safety glasses, ensures protection from unexpected leaks or splashes during installation. Furthermore, confirm that you have basic emergency procedures in place, including knowing where water shut-off valves are located, which can provide peace of mind during the installation process.

5. INSTALLING THE VALVE ONTO THE PIPE

Following the preparation, you can finally proceed to the installation of the valve onto the pipe. First, measure the size of the existing pipes and determine any necessary adjustments for the valve dimensions.

Carefully cut the existing pipes with a pipe cutter. Ensure that the cuts are clean and straight, which is essential for a snug fit. The installation should typically be approached methodically, aligning the valve without rushing. For connecting the valve, use the appropriate fittings—sometimes, elbow joints or connectors are necessary depending on your system layout.

When making the connections, apply sealant or thread tape to the threaded areas to create a robust, leak-proof seal, which is vital for maintaining system integrity. After placing the valve, secure it adequately, and double-check alignments before tightening fully, as misalignments can lead to undue stress on the system.

6. TESTING AND ADJUSTING THE SYSTEM

Post installation, the next stage revolves around testing the system for function and leaks. This is a critical phase to verify that the installation adheres to safety standards and operate as anticipated. Initially, restore water supply to the solar system, allowing it to fill gradually. Monitor all connection points for any signs of pressure loss or leakage.

While the system fills, it may be beneficial to activate the solar heating system to ensure the valve operates correctly in its intended function. During this testing process, confirm that the overflow valve opens at pressure levels specified by the manufacturer. This verification often requires monitoring pressure gauges present in the system, ensuring they reach the designated activation threshold.

In case of any leaks, your immediate focus must be on shutting off the system again to address such issues. Often, a situation as simple as an overtightened fitting or an insufficient seal can necessitate repeat examinations or adjustments until confidence in the installation is established.

7. MAINTENANCE AND LONG-TERM CARE

Once the installation completes, focusing on maintenance and long-term care will ensure the solar overflow valve and the overall system continues to operate effectively. Regular checks should be part of your maintenance routine, scrutinizing the valve for any signs of wear or degradation.

Consider scheduling inspections at least once or twice annually, or more frequently to coincide with seasonal system checks. Look for cracks, corrosion, or any irregularities in both the valve and surrounding connections. Identifying small issues early can lead to less complicated and more cost-effective repairs down the line.

In addition to visual inspections, periodic testing of the valve functionality is wise. Activating the overflow valve under controlled conditions can affirm that it responds correctly under pressure, which is essential for ensuring system safety. Keeping records of maintenance and tests helps track performance over time and offers insight into when substantial replacements might become necessary.

FAQs

WHAT IS A SOLAR OVERFLOW VALVE AND HOW DOES IT WORK?

A solar overflow valve serves as a critical component in solar heating systems by channeling excess fluid away from the system to prevent overpressure situations. When fluid expands due to heating, or there’s an increase in pressure beyond the capacity of the system, the overflow valve opens up to divert the excess fluid, ensuring safety and preventing potential damage such as pipe bursts or leaks. The mechanism functions based on pressure differentials; if the pressure exceeds a predetermined level, the valve activates, helping to maintain optimal operating conditions. Ultimately, it plays a vital role in preserving the integrity and longevity of your solar heating system.

CAN I INSTALL A SOLAR OVERFLOW VALVE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While many homeowners may feel empowered to undertake a solar overflow valve installation themselves, it greatly depends on their comfort and expertise with plumbing and solar systems. Individuals with a solid understanding of plumbing principles, along with experience in working with solar systems, may successfully complete the installation independently. However, for those lacking experience, hiring a qualified professional can ensure proper installation and adherence to safety standards, thus mitigating risks of future issues. If uncertain about the undertaking, engaging a professional can help ensure the system functions correctly and efficiently, providing peace of mind.

WHAT MAINTENANCE IS REQUIRED FOR A SOLAR OVERFLOW VALVE?

Maintaining a solar overflow valve involves regular inspections and testing to ensure optimal performance. You should perform visual checks at least once a year, examining the valve for any signs of wear, damage, or leaks. Additionally, periodic testing of the valve’s functionality allows you to confirm that it responds correctly to pressure changes. This may involve simulating conditions that would normally activate the valve. Keeping clear records of maintenance activities will help diagnose any emerging issues over time, making adjustments or replacements easier when they become necessary. Proper maintenance prolongs the life of both the valve and the solar heating system.

Maintaining a solar overflow valve involves essential tasks that help to ensure optimal functionality and efficiency of a solar heating system. Regular visual checks and functional tests are paramount. Individuals should plan for visual inspections at least once a year. During these checks, inspect the valve for obvious signs of wear, including fractures, corrosion, and leaks. Should any irregularities arise, addressing them quickly becomes crucial to prevent larger issues that may occur. For testing, it is wise to simulate conditions that would typically engage the valve, verifying that it opens within expected pressure parameters. Similarly, maintaining clear records of maintenance activities, including dates and specifics of inspections or repairs, can provide valuable insights into the system’s performance over time. Ultimately, a well-maintained solar overflow valve not only ensures system reliability but also contributes to the longevity of the entire setup.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-a-solar-overflow-valve/