To install a float valve on a solar barrel effectively, several essential steps must be followed. 1. Gather necessary materials, including a float valve compatible with your barrel size, appropriate tools (like a drill, wrench, and screwdriver), and Teflon tape for sealing. 2. Identify the correct location on the barrel where the float valve will be installed to ensure optimal water level control and minimal water loss. 3. Prepare the barrel by ensuring it is clean and dry at the installation site. 4. Attach the float valve securely following specific installation instructions to prevent any leaks that may occur during operation or post-installation.

The float valve, designed to automatically regulate water levels, plays a crucial role in maintaining consistent water availability for solar heating systems. Moreover, a well-installed float valve ensures minimal manual intervention, enhancing the overall efficiency and reliability of the solar barrel system. By following these steps, one can ensure a successful installation leading to a well-functioning solar water heating setup.

1. UNDERSTANDING FLOAT VALVES

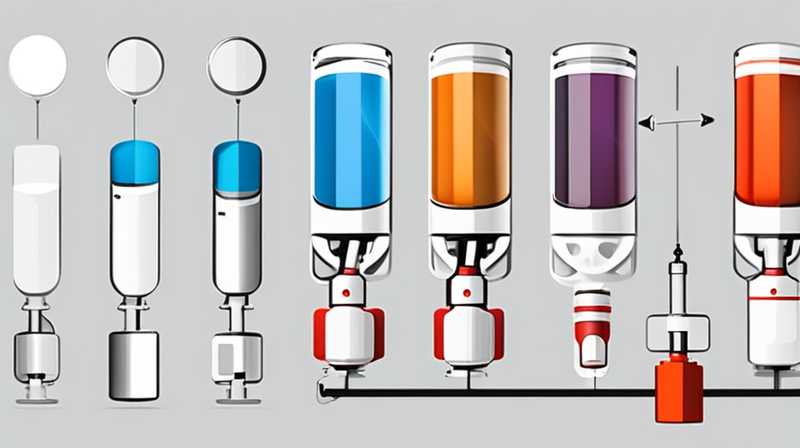

The float valve serves as an intricate part of many water systems, particularly in applications involving barrels, tanks, or cisterns. This device operates by utilizing a buoyant float that rises and falls with the water level, providing insights into the overall efficiency of water distribution systems. When installed correctly, this mechanism aids in maintaining an optimal water level, minimizing overflow and conserving resources.

The engineering behind float valves shows remarkable precision, ensuring that the valve opens and closes seamlessly in response to fluctuating water levels. Through this automatic process, the float keeps a consistent level within the barrel, contributing to efficient water usage and optimal solar energy harnessing. In contexts where water scarcity is an issue, float valves stand as a testament to smart resource management, allowing for dependability and sustainability in water utilization.

2. NECESSARY MATERIALS FOR INSTALLATION

Before embarking on the installation journey, assembling an appropriate toolkit is vital. Essential materials include a compatible float valve suited for the dimensions and type of your solar barrel, which can vary based on the manufacturer. Additionally, having a drill for creating holes, a wrench for tightening and securing connections, and a screwdriver is imperative to ensure a smooth process.

Moreover, consider incorporating Teflon tape to provide effective sealing around threaded connections. This small yet crucial component helps prevent leaks, which can be detrimental to the float valve and the solar barrel system. Inspection of the existing barrel is also recommended, examining for cracks or imperfections that could compromise the installation integrity. Securing high-quality components contributes to long-lasting performance, enabling the float valve system to function properly in conjunction with your solar barrel.

3. PREPARING THE BARREL FOR INSTALLATION

Thoroughly preparing the barrel for the float valve installation is a step that should not be overlooked. Ensure that the barrel is empty and clean, free from any debris, dirt, or contaminants that could interfere with the float valve’s operation. A clean surface will support a secure installation while minimizing future maintenance requirements.

Prior to installation, an examination of the barrel’s current state is essential. This involves checking for structural integrity, ensuring there are no leaks or damages that could lead to complications. Alongside a physical inspection, determining the perfect site for the float valve is crucial; it should be positioned at an optimal height to facilitate effective water level monitoring. Proper planning at this stage sets the groundwork for a successful installation, ensuring the longevity and effectiveness of the system.

4. INSTALLATION PROCESS IN DETAIL

With the preparations finalized, move into the actual installation process. Begin by marking the desired location on the barrel where the float valve will be installed, ensuring it aligns with the height measurement predefined. Use the drill to create an appropriately sized hole for the valve, which requires attention to detail. Precision in this step will help avoid unnecessary complications later in the installation process.

After creating the hole, install the float valve by threading it into the prepared opening. Secure it tightly with the wrench, ensuring it is snug enough to prevent leaks without over-torquing, which can damage the valve. An important component to this process involves wrapping Teflon tape around the valve threads, providing extra sealing protection. Make sure to test the valve by filling the barrel to check for leaks; this step is crucial for ensuring the longevity and effective operation of the installed valve.

5. TESTING THE INSTALLATION

Once the installation process concludes, the next step is comprehensive testing to ascertain that the float valve functions as intended. Gradually fill the barrel with water, closely monitoring the float valve’s movement and its ability to adjust the water level. Observe how the float rises and falls within the barrel, seeking any irregularities that might indicate problems in the installation.

Pay attention to the valve’s responsiveness; it should automatically close when the optimal water level is reached and open again when the water level decreases. Conducting a thorough test allows for identifying any potential issues, such as leaks, that may require immediate attention. Early detection of problems can save time and resources, ensuring that the entire system remains functional and efficient in the long run.

6. MAINTAINING YOUR FLOAT VALVE

Ensuring the longevity of your float valve necessitates regular maintenance checks. It is advisable to periodically inspect the valve for any signs of wear, residues, or debris that might inhibit its operation. Regular maintenance not only extends the life of the valve but also enhances the overall efficiency of the solar barrel system.

Cleaning the valve periodically allows it to function without obstruction, ensuring that it maintains the desired water levels effectively. If problems arise during function, such as the valve not closing properly or leaks forming around the seal, investigate and address these issues promptly. Well-maintained float valves promise adequate water management, playing a critical role in creating a sustainable and efficient solar water heating system.

FREQUENTLY ASKED QUESTIONS

WHAT IS A FLOAT VALVE, AND HOW DOES IT WORK?

A float valve is a mechanism designed to regulate water levels in tanks, barrels, or cisterns by automatically open or closing based on the float’s position in the water. The float rises or falls with the level of water, triggering the opening or closing of the valve. This automatic process ensures that once the desired water level is reached, the flow of water is stopped, preventing overflow. Conversely, when the water level drops, the float descends, reopening the valve to allow water to flow back into the system.

The operational efficiency of float valves in capturing water from various sources, including rainwater systems, is paramount in applications to conserve water resources. Discerning the intricacies in float valve functionality will aid individuals in choosing the right model for their requirements, leading to better overall water management.

HOW DO I KNOW IF THE FLOAT VALVE IS WORKING PROPERLY?

Determining whether the float valve functions correctly necessitates a systematic approach. Begin by visually inspecting the valve for any signs of debris or damage that could affect its performance. Fill the barrel gradually with water, watching how the float responds to the changing water levels. A properly functioning valve will open to allow water to flow in when the level drops and close when the desired level is achieved.

If the float valve remains closed when the water level is low or fails to close when the level is reached, it may indicate a malfunction. Regular maintenance checks, looking for leaks or unusual noises, are essential for ensuring that the valve retains its operational integrity over time. Implementing these measures results in efficient management of water levels, reinforcing the float valve’s role in a sustainable system.

CAN I INSTALL A FLOAT VALVE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

The installation of a float valve can typically be handled as a do-it-yourself project, provided that the individual possesses basic mechanical skills and tools needed for the task. Engaging in research to understand the dimensions and compatibility of the valve with the existing system is crucial. Following installation guides or manufacturer instructions with diligence can yield a successful outcome.

However, in cases of complexity or uncertainty, consulting a professional may be advantageous. A qualified expert can ensure a proper installation, minimizing potential risks associated with improper setup, such as leaks or operational inefficiencies. Ultimately, the decision depends on individual confidence and comfort level with mechanical tasks, but the availability of professional assistance is always a viable option for those in doubt.

In light of the information provided, installing a float valve on a solar barrel encompasses several critical steps, from preparation to installation and maintenance. Understanding the functionality and significance of the float valve contributes to efficient water management and enhanced solar system performance. Engaging proactively during installation ensures optimal outcomes, highlighting the tool’s role in sustainable living practices. Through diligent examination of necessary materials, informed planning during installation, and consistent maintenance, individuals can maximize the effectiveness and longevity of their water systems. Being diligent in these steps leads to an effective and reliable solar barrel system. The importance of understanding float valves cannot be overstated, especially in the growing context of environmentally conscious practices that aim to ensure sustainable resource utilization. By delving deeper into this aspect of solar heating, one ultimately invests in both personal utility and broader environmental health.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-a-float-valve-on-a-solar-barrel/