To install 16 pipes of a solar barrel, specific steps must be observed. 1. Preparation, verify the location and necessary tools. 2. Layout, outline the design for pipe placement. 3. Assembly, connect the pipes carefully ensuring secure fits. 4. Testing, assess the system for leaks and functionality. 5. Finalization, adjust any elements for optimized performance. The most crucial point is the assembly process; it involves precise measurements, appropriate fittings, and careful handling to avoid future leaks and ensure efficient operation. This step dictates the overall success of the installation and directly impacts the efficiency of the solar heating system.

1. PREPARATION

The initial phase of any installation process necessitates adequate preparation. Prior to embarking on the actual task of installing the 16 pipes of a solar barrel, effective planning is imperative. Assessing the site where the installation will take place ensures that environmental conditions such as sunlight exposure, wind direction, and proximity to heat sources are taken into account.

Identifying the tools required for this undertaking is another critical aspect of preparation. Essential instruments may include pipe cutters, wrenches, seals, and any other fitting tools. Familiarity with these tools can substantially augment efficiency during installation. Furthermore, collecting all needed components beforehand will prevent interruptions that could arise from searching for parts after the process has commenced.

Throughout the preparation stage, attention to detail must be paramount. Any oversight in this stage could lead to significant complications later on, which emphasizes the importance of thorough planning and organization. An efficient preparation phase not only facilitates a smoother installation but also serves as a foundation for the entire project.

2. LAYOUT

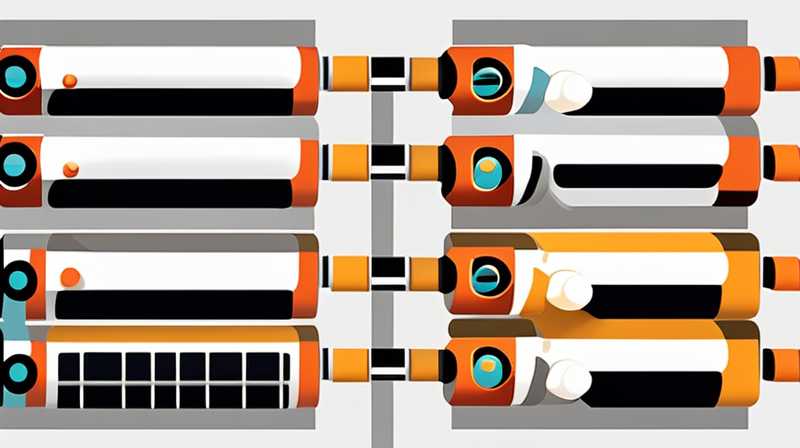

Once the initial planning stages are completed, the next step entails strategizing the layout of the solar barrel pipes. This involves both the positioning and the design of the pipe arrangement. Determining the optimal configurations can greatly influence the efficacy of the solar heating system.

A detailed map of the proposed layout should reflect the positioning of each pipe. This blueprint allows for a systematic approach to installation by illustrating the precise distances and angles at which pipes will be placed. When determining placement, geographical factors such as slope and sun exposure must be thoroughly examined. This ensures not only convenience but also enhances the solar energy harvesting capacity of the system.

Additionally, one must consider potential environmental obstructions that could negate the advantages of the chosen layout. Objects like trees or buildings casting shadows could drastically reduce the system’s efficiency. While laying out the plan, an assessment of future growth in the area and potential modifications to the space may also be warranted. This foresight is essential for sustaining the system’s performance in the long term.

3. ASSEMBLY

The assembly of the solar barrel pipes requires a meticulous approach to ensure all components fit together correctly. When executing this stage, it is imperative to pay attention to the selection of appropriate fittings and seals for the pipes. Correct assembly practices are vital to avert leaks and ensure that the system operates efficiently over an extended period.

As each piece is fitted together, it is essential to adhere to the specifications outlined in the manufacturer’s instructions. These guidelines often provide detailed steps on how to connect each pipe, the order of assembly, and specific torque requirements necessary for secure fittings. An understanding of these technical details helps mitigate any potential misalignments during assembly.

Moreover, it is recommended to conduct periodic check-ins throughout the assembly process. This may include verifying that all pipes are level and aligned correctly, as minor deviations can lead to significant issues down the line. Proper assembly not only enhances the functionality of the system but also assures longevity.

4. TESTING

After the assembly is completed, the next phase is focused on testing the entire system. Rigorous evaluation is crucial to ascertain that everything operates as intended. Listening for any unusual sounds, observing for leaks, or detecting changes in fluid pressure can all indicate issues that may need addressing.

In addition to physical checks, a pressure test could be performed to ensure that the pipes can withstand the operational pressure without any compromise. It is common to encounter minor issues during this phase, such as small leaks or misalignments, which should be rectified immediately.

Proper testing guarantees that the installation is not only functional but reliable as well. An efficient solar barrel system minimizes maintenance costs over time, so ensuring it operates flawlessly from the outset is crucial. A thorough round of testing aligns the system for optimal performance and prevents future malfunctions that could disrupt energy efficiency.

5. FINALIZATION

With the system fully assembled and tested, the finalization of the project consists of wrapping up all loose ends. This process may include securing any exposed piping, ensuring everything is correctly insulated, and conducting a final review of the entire layout. Proper finishes improve the aesthetic of the installation while also shielding the components from environmental damage.

It may also involve educating users or stakeholders about the system’s functionality and maintenance requirements. This training may cover essential topics, including understanding energy output metrics or recognizing signs of system malfunctions. Involvement of the living entity plays an integral role in the ongoing efficiency of the solar barrel.

In sum, finalizing an installation should not be taken lightly. This last step solidifies not only the physical work completed but also assures stakeholders of ongoing support for any future queries or needs for maintenance. The longevity of the system depends significantly on the attention given to the last stages of the installation process.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE REQUIRED FOR INSTALLING SOLAR BARREL PIPES?

For installing solar barrel pipes, various materials are essential. A primary component includes the pipes themselves, which are often made from materials such as PVC or copper, chosen for their durability and thermal conductivity. Fittings, including connectors, elbows, and tees, allow for the correct assembly of the pipes and provide necessary turns and junctions. Insulation material is also crucial, as it helps maintain heat within the system, optimizing energy collection. Additional components may include valves, gauges, and seals to enhance functionality and provide monitoring options. Having access to the appropriate materials not only ensures a smoother installation but also enhances the overall effectiveness of the solar heating system.

HOW LONG DOES IT TAKE TO INSTALL A SOLAR BARREL PIPE SYSTEM?

The duration of installing a solar barrel pipe system can vary significantly based on several factors. Primarily, the complexity of the design plays a pivotal role, as any intricate designs may require additional time for precise assembly. In general, simpler systems might take approximately 8 to 12 hours for completion, while more complex setups could extend this duration to two days or more. The expertise level of the installers also contributes to the timeline; experienced professionals may complete the task more swiftly than novices due to their familiarity with the process. Nevertheless, it is essential to allocate ample time for thorough preparation, assembly, testing, and finalization to ensure the system’s longevity and proper functionality.

CAN I INSTALL A SOLAR BARREL SYSTEM MYSELF?

Choosing to install a solar barrel system independently is feasible, but it requires a thorough understanding of the installation process, tools, and materials involved. One must possess a solid comprehension of plumbing and heating principles, as well as the operational mechanics of solar energy systems. If the individual has experience with similar projects, then it could further aid in the success of the installation process. However, it’s crucial to consider the potential challenges and ensure all safety measures are implemented. Consulting professional installers, even to verify one’s work, can significantly enhance confidence in the installation while improving the system’s efficacy. Ultimately, whether undertaking this project alone or hiring professionals, a strong commitment to do it correctly is essential for long-term performance.

In summary, properly installing 16 pipes of a solar barrel entails several crucial steps that cannot be overlooked. The success of such an installation relies significantly on rigorous preparation, thoughtful layout design, precise assembly, thorough testing, and systematic finalization. Each phase builds upon the previous, ensuring a comprehensive approach that maximizes efficiency and longevity of the solar heating system. The critical aspect of the entire process is the assembly of the pipes; ensuring they are connected securely and appropriately will ultimately define the system’s functionality. Such commitment to quality within each stage guarantees not only immediate operational success but also enduring reliability over time, fostering environmental sustainability through the effective utilization of solar energy. Given the complexities involved, whether undertaken independently or with professional guidance, meticulous attention to every detail is paramount in realizing a successful installation. Adhering to these principles reflects a serious commitment to both craftsmanship and sustainable practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-16-pipes-of-solar-barrel/