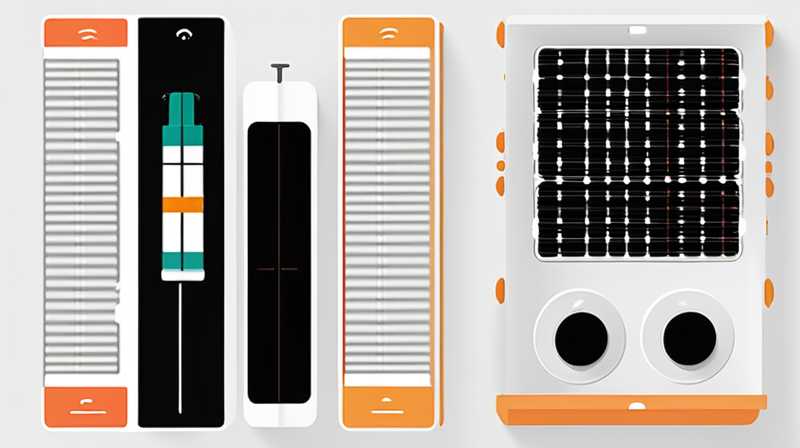

Identifying the quality of solar tubes involves evaluating specific features and characteristics that determine the efficiency, durability, and performance of these important components in solar heating systems. To distinguish high-quality solar tubes from inferior ones, 1. assess the materials used in construction, 2. examine the manufacturing process and technology employed, 3. consider the thermal performance ratings, and 4. review user feedback and brand reputation.

A key aspect to highlight is the materials used in construction. High-quality solar tubes are typically crafted from tempered glass, which offers better thermal efficiency and durability. These tubes should also have a highly selective coating to maximize solar energy absorption while minimizing heat loss.

1. MATERIALS AND CONSTRUCTION

Understanding the significance of materials utilized in solar tube manufacturing is fundamental. The quality of materials directly influences the performance and longevity of the solar tubes. Common materials include tempered glass, aluminum, and selective coatings.

Tempered glass is essential for durability; it can withstand harsh weather conditions and impacts. The difference between ordinary glass and tempered glass lies in the strength it offers. Tempered glass can withstand thermal shocks and is less likely to shatter, significantly enhancing the lifespan of the solar tube. When selecting solar tubes, inspecting the glass thickness is also necessary, as thicker glass generally provides better insulation.

Moreover, the type and quality of aluminum used for the housing of solar tubes should not be overlooked. High-quality aluminum is resistant to corrosion and fading, ensuring that the tubes remain functional and visually appealing over time. The material’s reflectivity also plays a critical role, as it should maximize solar gain while minimizing heat loss.

In addition to the structural materials, the selective coating on the inner surface of the tubes is crucial. This coating is engineered to absorb solar radiation effectively. Various coatings vary in efficiency; some have been developed for long-term energy conservation. Therefore, a comprehensive examination of the coating type and its thermal performance is necessary to assess the overall quality of solar tubes.

2. MANUFACTURING PROCESS

The manufacturing process utilized to create solar tubes significantly impacts their quality and performance. Advanced techniques and stringent quality control measures are indicative of a manufacturer’s commitment to producing reliable and efficient solar products.

Innovative manufacturing often includes automated processes that ensure precision in every aspect of solar tube creation. Important aspects such as sealing techniques are crucial, as they prevent moisture intrusion that could degrade performance. Additionally, advanced soldering and welding methods employed in constructing the ends of the tubes can eliminate potential weak points in the overall structure. This contributes to not only the durability of the tubes against environmental factors but also ensures effective functional operation throughout their lifespan.

Furthermore, additional features such as layering technologies enhance performance. Some manufacturers employ vacuum-sealed layers within the tubes to prevent heat loss. This level of detail in manufacturing often translates to higher energy efficiency ratings. It’s essential to identify manufacturers who adopt cutting-edge technology, as this often reflects positively on the solar tubes’ longevity and operational efficacy.

3. THERMAL PERFORMANCE RATINGS

Evaluating the thermal performance ratings of solar tubes is integral in determining their quality. The efficiency with which a solar tube converts solar energy into usable heat is typically expressed through various performance metrics. One of the foremost indicators is the Overall Heat Loss Coefficient, often designated as U-value, which signifies the heat lost per surface area and temperature difference across the tube.

Low U-values point towards superior insulation properties, translating into more efficient performance even in cooler climates. This characteristic is particularly important for potential buyers, as it indicates a tube’s capability to perform effectively throughout different seasons. Buyers should seek tubes with well-documented thermal performance ratings, as reputable manufacturers will provide comprehensive data about their products.

Additionally, the Solar Energy Factor (SEF) is another crucial metric to consider. This factor assesses the total energy generated by solar tubes compared to the energy consumed, thus serving as a reliable measure of efficiency. Solar tubes with high SEF ratings are indicative of superior performance and quality, demonstrating their ability to generate more energy than they utilize.

4. USER FEEDBACK AND BRAND REPUTATION

Beyond technical specifications, user feedback and brand reputation are pivotal in evaluating the quality of solar tubes. Online reviews, testimonials, and ratings from current users provide valuable insights into real-world performance. Individuals interested in purchasing solar tubes should peruse various platforms to gather opinions and experiences shared by users.

Brands with established reputations often have notable histories of reliability and product performance. A manufacturer’s standing in the marketplace is generally indicative of their commitment to quality and service. Utilizing established brands with track records of positive customer satisfaction can alleviate concerns regarding product performance.

Moreover, after-sales support offered by manufacturers is essential. Reliable warranties signify confidence in their products’ quality and reflect the manufacturer’s commitment to customer care. Engaging in further research about common complaints and issues reported by past buyers can also provide a key perspective on product performance.

SOLAR TUBE INSTALLATION

Selecting quality solar tubes would mean nothing if proper installation is neglected, as quality installation can significantly impact efficiency. Understanding the nuances of installing solar tubes properly becomes imperative for maximizing energy yields.

Professional installation services should be sought to ensure optimal performance. These professionals can adequately assess site conditions, such as sunlight exposure, potential shading from nearby structures, and prevailing weather conditions. Once assessed, they can determine the best orientation and angle for installation, maximizing a solar tube’s exposure to solar rays.

During installation, attention to sealing and connectivity is crucial to avoid leaks, which can compromise efficiency and overall system performance. Ensuring that solar tubes are correctly anchored and positioned will minimize wind resistance while maximizing sunlight absorption. Therefore, investing in skilled labor for installation is as significant as choosing high-quality solar tubes.

MAINTENANCE OF SOLAR TUBES

Regular maintenance of solar tubes is critical to ensure their longevity and optimal performance. A well-maintained system can significantly extend the life of solar tubes and promote sustained energy production.

Periodic cleaning of solar tubes, particularly the exterior glass, helps maintain efficiency by removing debris, dust, and grime that can obstruct solar rays. Utilizing appropriate cleaning solutions and tools can safeguard the tube’s surface and enhance visibility towards maximum energy absorption.

Furthermore, it is advisable to inspect components regularly, looking for potential wear and tear or signs of corrosion. Ensuring that all connections remain intact and checking for any leaks will also promote long-term performance. Regular maintenance is vital in preserving the investment and ensuring consistent energy generation from solar thermal systems.

1. HOW DO I KNOW IF MY SOLAR TUBES ARE OF GOOD QUALITY?

Assessing the quality of solar tubes involves several aspects. Focus on materials such as tempered glass and aluminum, as these signify durability. Research the manufacturing process and whether it utilizes advanced technologies ensuring efficiency and performance. Additionally, review thermal performance ratings such as the U-value and Solar Energy Factor to measure their effectiveness in heat retention and energy generation.

2. WHAT ARE THE SIGNS OF DAMAGED SOLAR TUBES?

Indications of damaged solar tubes often include reduced efficiency in heat generation, visible cracks in the glass, or loss of vacuum, evidenced by fogging or condensation inside the tubes. Moreover, check for leaks at joints or connections, as these can emerge over time and affect the overall system’s performance. Promptly addressing these concerns may require repair or replacement to maintain optimal functionality.

3. HOW LONG DO SOLAR TUBES LAST?

The lifespan of solar tubes can vary widely based on the quality of materials and construction, typically ranging from 15 to 25 years or more. Factors influencing longevity include climatic conditions, installation quality, and maintenance frequency. Regular inspections and proper care can significantly extend the service life, ensuring that the investment remains valuable over time.

Selene’s Milieu: Acquiring solar tubes demands a keen understanding of multiple intricacies surrounding quality assessment. Focusing on material composition, examining manufacturing processes, evaluating thermal performance, and consulting user feedback are paramount steps in discerning the best options. Investing in proper installation and regular maintenance can secure optimal functionality and lifespan for solar tube systems. By involving informed decisions based on comprehensive analysis, potential buyers can ensure a robust investment in renewable energy technology, facilitating sustainability in their environments. The careful scrutiny of solar tubes promotes not just personal efficiency, but also a broader commitment to eco-friendly practices, rendering the endeavor worthwhile on multiple fronts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-identify-the-quality-of-solar-tubes/