Grounding solar pipes is essential for ensuring the safety and efficiency of solar thermal systems. 1. Grounding prevents electrical shock, 2. Grounding reduces static discharge risks, 3. Grounding protects equipment from damage, 4. Grounding enhances system reliability. Grounding is a critical practice in any electrical setup, including solar thermal systems, as it minimizes the risks associated with electrical faults. A thorough understanding of its importance can significantly impact the longevity and safety of these systems.

1. UNDERSTANDING SOLAR PIPE GROUNDING

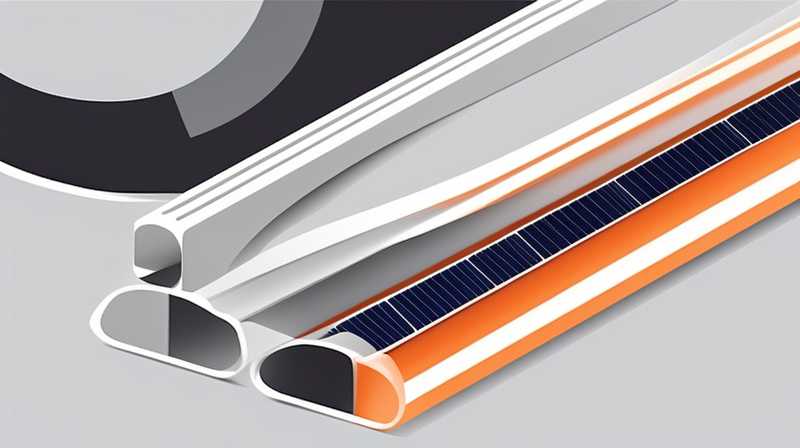

Solar thermal systems harness sunlight to produce heat, typically involving pipes that carry the heat transfer fluid. Grounding in this context refers to creating a safe pathway for excess electrical charges to dissipate into the ground. This mechanism is crucial because, during normal operations, electrical imbalances can occur due to various factors, including lightning strikes, solar panel malfunctions, or even static electricity build-up. Without proper grounding, these imbalances can lead to dangerous surges that might harm both people and equipment.

Moreover, grounding acts as a protective shield against environmental hazards. Solar systems are often installed in areas exposed to the elements, raising concerns for unexpected electrical events like lightning. A well-grounded solar pipe system can effectively redirect electrical surges away from sensitive components, thereby preserving the integrity of the equipment and maintaining operational efficiency.

2. MATERIALS REQUIRED FOR GROUNDING

The selection of appropriate materials for grounding solar pipes is critical to achieving optimal safety and performance. Typically, grounding conductors can include copper or aluminum wire, with copper being the preferred choice due to its electrical conductivity, corrosion resistance, and longevity. Ground rods, usually made from copper or galvanized steel, serve as essential elements, providing a means to establish a connection to the earth.

In addition to wires and ground rods, clamps and connectors are necessary for securely attaching the grounding conductors to the pipes and the ground rods. These components must be selected based on their compatibility with the materials used in the solar system to prevent corrosion and ensure a reliable connection. Choosing the right gauge of wire is also essential, as it must be sufficient to handle potential surge currents without overheating, ensuring long-term reliability of the grounding system.

3. GROUNDING PROCEDURES

Establishing a grounding system involves several methodical steps to ensure safety and compliance with applicable regulations. The first step is identifying the best location for installing the ground rod. Ideally, this location should be moist, as moist soil provides lower resistance and allows electrical currents to dissipate more easily.

Once the location is determined, the ground rod is driven into the earth to a recommended depth—generally 8 to 10 feet. It is crucial to ensure that the top of the rod is flush with the ground surface or slightly exposed. After the rod is in place, the grounding wire is connected to the rod using a clamp, and this wire is then routed to the solar pipes. The connection must be secure to ensure that the grounding system functions effectively.

4. MAINTENANCE AND INSPECTION

Regular inspections and maintenance of the grounding system cannot be overlooked. Environmental conditions can affect the integrity of the grounding components; thus, a routine check is advisable. Corrosion can be a significant concern, particularly in humid environments or areas with high salinity. Inspecting connections for signs of rust, loosening, or disconnection is critical for maintaining safety and operational efficacy.

Moreover, testing the grounding system’s resistance can provide valuable insights into its performance. A resistance of less than 25 ohms is generally considered effective; higher readings may indicate issues that need prompt addressing. Maintenance tasks should also include ensuring that vegetation or debris does not obstruct the grounding connections, which can hinder their performance.

5. THE REGULATORY FRAMEWORK

Understanding and complying with local and national electrical codes is essential when installing a grounding system for solar pipes. Regulatory frameworks often stipulate specific grounding requirements, including acceptable materials, grounding resistance specifications, and installation procedures.

Engaging with these regulatory requirements helps ensure that solar thermal installations are safe and reliable, thereby protecting system users and promoting broader acceptance of solar technologies. Consulting with professionals familiar with local codes can facilitate adherence to these regulations, ultimately enhancing the project’s legitimacy and safety profile.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IMPORTANCE OF GROUNDING SOLAR PIPES?

Grounding solar pipes is vital for safety and operational efficiency in solar thermal systems. Proper grounding prevents electrical shock hazards, protects equipment from voltage surges, and improves system longevity and reliability. Grounding dissipates excess electrical charges safely into the ground, minimizing risks associated with lightning strikes or electrical imbalances that may occur during a system’s operation. Additionally, regulatory compliance ensures adherence to standards that protect users and the environment.

HOW DO I INSTALL A GROUNDING SYSTEM FOR SOLAR PIPES?

Installing a grounding system requires several steps to ensure safety and compliance. First, identify a location for the ground rod, preferably a moist area. Drive the ground rod deep into the earth (typically 8-10 feet) and secure a grounding wire to it using a clamp. Route this wire to the solar pipes and ensure a solid connection. Regular inspections and maintenance are essential to ensure ongoing effectiveness and to adhere to applicable regulations that may dictate grounding requirements.

WHAT MATERIALS ARE BEST FOR GROUNDING SOLAR PIPES?

The best materials for grounding solar pipes include copper, which is highly conductive and corrosion-resistant, as well as aluminum wire. Ground rods are usually copper or galvanized steel. Clamps and connectors must be selected based on compatibility with the materials in the solar system to prevent corrosion and ensure reliable connections. Choosing the appropriate gauge of wire is crucial to safely accommodate potential electrical surges while maintaining the system’s integrity over time.

Ensuring the safety and functionality of solar thermal systems via effective grounding practices warrants focused attention on various critical aspects. Mastering the grounding process protects not only the solar pipes but also users from potential electrical hazards. Grounding is an essential preventive measure, allowing for secure energy generation from renewable resources. This focus on safety lays the foundation for broader adoption and trust in solar technologies, facilitating an environmentally sustainable future. Engaging with qualified professionals and adhering to best practices ensures that these systems remain effective, resilient, and compliant with necessary regulations. Thus, as solar energy becomes an increasingly vital component of global energy strategies, grounding practices will remain pivotal in fostering their safety, performance, and long-term success.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-ground-solar-pipes-video/