1. Solar panels can be effectively attached using strong adhesives, ensuring a secure long-term bond. 2. The process requires careful surface preparation, including cleaning and drying, to enhance adhesion. 3. Selecting the right adhesive is crucial; options include silicone, epoxy, and polyurethane. 4. Follow specific instructions for the adhesive to achieve optimal results, ensuring it is suitable for outdoor use. 5. Monitor the panels post-installation for any movement or detachment to address issues promptly.

INTRODUCTION TO SOLAR PANEL ADHESIVES

Adhesives play a pivotal role in securing solar panels in various installations. Understanding the nuances of applying glue allows users to make informed decisions regarding the longevity and stability of their solar systems. While many opt for professional installation, there exists a significant segment that prefers manual application due to cost-effectiveness or personal preference. This guide serves to demystify the process and deliver comprehensive insights into gluing solar panels manually.

Choosing the right adhesive is paramount in ensuring a steadfast attachment. The market presents several options, each with distinct specifications and suitability suited for different materials and weather conditions. The criteria for selection often hinge upon the environmental conditions, the material of the panels, and the substrate to which they will be adhered. Furthermore, surface preparation is equally critical, as failure in this area could lead to inadequate bonding and subsequent detachment.

CHOOSING THE RIGHT ADHESIVE

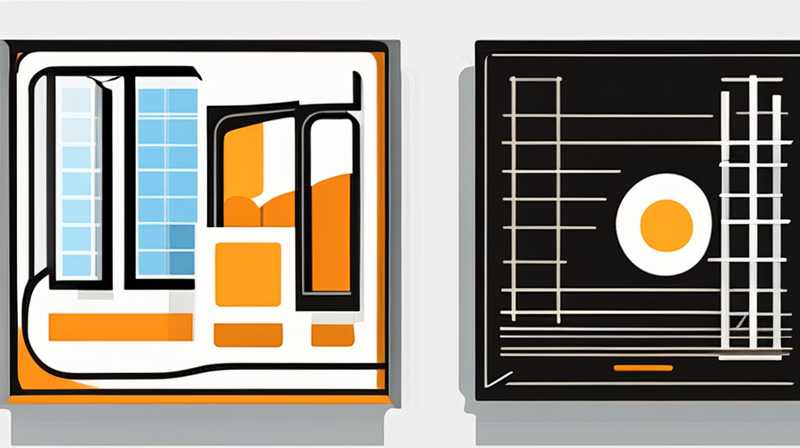

The plethora of adhesives available can be overwhelming, yet each has its unique set of advantages. Among the most popular choices are silicone sealants, polyurethane adhesives, and epoxy resins. Each of these adhesives offers distinct characteristics that cater to specific needs and surfaces.

SILICONE SEALANTS are particularly favored for their flexibility and resistance to moisture. They bond excellently with diverse materials, making them suitable for a range of substrates. Moreover, silicone stands out for its UV resistance, ensuring longevity even under direct sunlight. However, caution must be exercised as not all silicone sealants are designed for structural bonding, so checking the manufacturer’s specifications becomes essential.

POLYURETHANE ADHESIVES, conversely, excel in situations where a rigid bond is required. Their structural integrity and resistance to environmental stresses underscore their advantage for applications on most materials. However, they do require adequate surface preparation and might not be suitable for certain flexible installations where movement is expected. For installations subjected to extreme temperatures or fluctuating conditions, polyurethane can offer a more durable solution.

Lastly, EPOXY RESINS are renowned for their durability and strength, making them the go-to adhesive in heavy-duty applications. They provide resistance to chipping, cracking, and moisture penetration. However, the application of epoxy is more time-sensitive, as it cures quickly, demanding swift action during installation. Understanding the distinct characteristics of these adhesives can lead to significantly better outcomes in solar panel bonding.

SURFACE PREPARATION IMPORTANCE

Effective surface preparation cannot be overstated in the quest for reliable adhesion. Panels and substrates must be thoroughly cleaned to remove any residues, dust, or moisture that may compromise the bond. Each type of material has its specific cleaning requirements, thus necessitating attention to detail during this phase.

CLEANING METHODS may include the use of solvents or non-abrasive detergents to ensure that the surfaces are pristine prior to application. For photovoltaic panels, a gentle approach is favorable to avoid damaging the surface. It is prudent to validate the compatibility of cleaning agents with the photovoltaic material itself to prevent any adverse reactions.

Following the cleaning process, attention should also be directed toward optimizing drying conditions. Surfaces must be entirely dry before proceeding with adhesive application, as moisture can inhibit bonding and potentially lead to long-term issues. Employing a lint-free cloth can aid in confirming that no traces of particles remain, contributing to the overall success of the bonding process.

APPLICATION TECHNIQUE

Implementing the adhesive correctly is crucial in achieving desired results. The technique varies based on the selected adhesive; however, general principles can guide the process for effective application.

ADHESIVE APPLICATION often involves even and continuous beads, ensuring complete coverage while avoiding excess. Using a caulk gun for silicone sealants can facilitate more precise application, significantly reducing the odds of over-application. With polyurethane, applying a generous amount at the edges can enhance bonding, while ensuring even distribution across the entire surface can provide adequate structural integrity.

For epoxy resins, particular care should be exercised in mixing components according to manufacturer specifications. A precise mix ratio ensures optimal performance, preventing issues with curing or bonding later. Utilizing applicators such as spatulas or brushes can aid in managing the flow and ensuring thorough contact with the surface.

Finally, aligning the panels carefully after application is paramount. Once placed, the bond may require some time to cure correctly. Securing the panels with temporary supports may mitigate any movement until curing is complete.

CURING TIME AND POST-INSTALLATION

Understanding the curing time for the chosen adhesive is critical. Different adhesives have varying curing durations that ultimately dictate how soon the solar panels can be operational.

DRYING AND CURING TIMES for silicones can range from a few hours to up to 24 hours for full strength. Polyurethane typically requires 24 hours for initial setting and may take up to several days to hit full strength. Epoxies, on the other hand, often harden in a relatively short time frame, but achieving full bond strength might take longer, depending on the formulation.

Monitoring the panels post-installation is essential to ensure everything remains secure throughout the curing phase. Regular checks within the initial days after installation can help identify any issues early on, preventing costly damage to both the panels and the mounting surface.

It’s also advisable to perform extensive checks after a significant weather event. Environmental factors like high winds, heavy rain, or snow accumulation can compromise the bond, necessitating prompt inspection and action if any signs of detachment are observed.

CARING FOR GLUED SOLAR PANELS

Once solar panels are installed, ongoing maintenance becomes necessary to ensure longevity and effectiveness. Regular inspections can help identify minor issues before they escalate into serious concerns.

INSPECTING THE SEAL can give hints about the adhesive’s performance. Cracking, peeling, or visible gaps may indicate deterioration that may ultimately require reapplication or additional securing measures. When assessing seal integrity, be wary of environmental wear and tear, as UV exposure and fluctuating temperatures can take a toll.

Cleaning solar panels periodically is also vital. Ensure they remain free of debris or contaminants that could reduce their efficiency. Using safe cleaning solutions ensures the effulgence of the panels is restored and promotes optimal energy absorption.

Monitoring performance metrics from the installation phase onward will provide a continuous understanding of panel efficiency. Significant declines in performance might hint at underlying issues, possibly related to the adhesive bond or misunderstandings in the installation process.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ADHESIVES ARE BEST FOR SOLAR PANELS?

When selecting adhesives for solar panel installation, three types are frequently recommended: silicone sealants, polyurethane adhesives, and epoxy resins. Silicone is often chosen for its flexibility and moisture resistance, making it an excellent choice for varied environmental conditions. Polyurethane provides a rigid bond, ideal for surfaces that encounter shifts or structures requiring high durability. Epoxy is recognized for its strength, especially in heavy-duty applications. Each of these adhesives has unique advantages, and the selection should depend on environmental conditions, material compatibility, and the specific project requirements. Before applying, always verify the manufacturer’s guidelines to ensure suitability and effectiveness in outdoor applications.

HOW DO I PREPARE THE SURFACES BEFORE APPLYING ADHESIVES?

Surface preparation entails several critical steps to guarantee optimal adhesion. First, the surfaces of both the solar panels and the mounting substrate should undergo thorough cleaning. This involves using non-abrasive cleaners or solvents tailored to the materials being used. Residue, dirt, or moisture can all negatively affect adhesive bonds. After cleaning, drying is equally important; even minor dampness can compromise adhesion. Typically, a lint-free cloth is advised for this purpose to avoid introducing additional debris. Ensuring the surfaces are smooth and uniform also enhances bonding. Taking these preparatory steps is crucial to the longevity and success of the glued solar panel installation.

WHAT SHOULD I WATCH FOR AFTER INSTALLATION?

After installation, several factors warrant ongoing attention. Begin by tracking the performance of the solar panels through energy output metrics. This monitoring will offer insights into potential adhesive issues or other installation flaws. Additionally, conduct routine visual inspections of the adhesive seal. Look for signs of deterioration such as cracks, peeling, or evidence of moisture intrusion. Weather-related checks are crucial, particularly after heavy storms or high winds. If any irregularities arise, immediate assessment and repair become essential to prevent compromising the system. Finally, understanding the adhesive’s curing time is crucial to avoid stress on the bond during this period.

AFTER-CURING MAINTENANCE AND LONGEVITY MEASURES

Maintaining the integrity of glued solar panels involves regular inspections and proactive measures. After the adhesive has fully cured, it is critical to observe the condition of the bond over time. Substantial fluctuations in temperature or harsh weather might lead to wear on the adhesive. Inspection intervals should be planned after significant environmental events to catch any potential issues early.

Additionally, regular cleaning can ensure panels are devoid of pollutants or contaminants that can impede performance. This ongoing care helps preserve the adhesive strength and the overall system efficiency, contributing to the long-term functionality of the solar installation. Keeping a log of inspections and maintenance provides insights that can guide future servicing needs.

***** The endeavor of attaching solar panels manually calls for a thorough understanding of the processes involved, from selecting suitable adhesives to ensuring an adequate environment for application. A meticulous approach to both preparation and execution can facilitate a robust bond that withstands the test of time. Engaging with environmentally friendly and weather-resistant adhesives will promote not only the functionality of the panels but also their stability in diverse conditions. Monitoring and maintaining the system can greatly extend its service life, thus yielding better returns on the initial investment. Ultimately, investing time and effort during adhesive selection, application, and upkeep can lead to a successful and sustainable solar energy project. The landscape of solar energy continues to evolve, and staying informed about best practices will empower users to harness the full potential of their installations. In the face of challenges, those who are proactive about care and monitoring will reap the benefits of a diligently maintained solar energy system. As solar technology further develops, so too should the methods of its implementation and maintenance, ensuring efficiency and resilience in an ever-changing environment. *****

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-glue-solar-panels-manually/